Have you ever faced a problem with your lathe carriage not moving? It can be so frustrating! Imagine planning to create an amazing project, but your lathe just won’t cooperate. You’re not alone. Many people encounter this common issue.

Some might wonder why this happens in the first place. It can feel a bit like a puzzle. But don’t worry, fixing it is not as hard as it may seem. With a little help, you can get your lathe working again.

Did you know that many people learn to solve this problem by trial and error? They often find simple solutions that work. With the right tricks and tips, you can quickly get your lathe carriage moving smoothly.

In this article, we will explore easy and effective ways to fix the lathe carriage. Whether you’re a beginner or a pro, you’ll find helpful ideas. Let’s dive in and get your projects back on track!

Lathe Carriage Not Moving Fix: Troubleshooting Solutions

Fixing a Lathe Carriage That Won’t Move

Is your lathe carriage stuck? This common issue can be frustrating, but there are simple fixes. Start by checking for debris or rust. Sometimes, a good cleaning is all it needs. Next, inspect the drive mechanisms and belts. They might be loose or damaged. If these steps don’t work, consider checking the lubrication. Proper oiling ensures smooth motion. Remember, a little maintenance goes a long way in keeping your lathe running well!Identifying the Signs of a Malfunctioning Carriage

Symptoms indicating the carriage is stuck or not moving. Potential causes of carriage movement failure.Noticing issues with the lathe? There are clear signs of a stuck or non-moving carriage. Watch for these symptoms:

- Strange noises when trying to move the carriage.

- The carriage does not respond to controls.

- Visible rust or dirt blocking movement.

Several factors can cause this problem:

- Poor lubrication prevents smooth action.

- Dirt buildup can create obstructions.

- Mechanical wear may hinder movement.

Fixing these issues early can save time and effort!

What are the common signs of a malfunctioning carriage?

Common signs include unusual noises, no response to commands, and visible blockage from dirt or rust.

Troubleshooting Steps to Diagnose the Issue

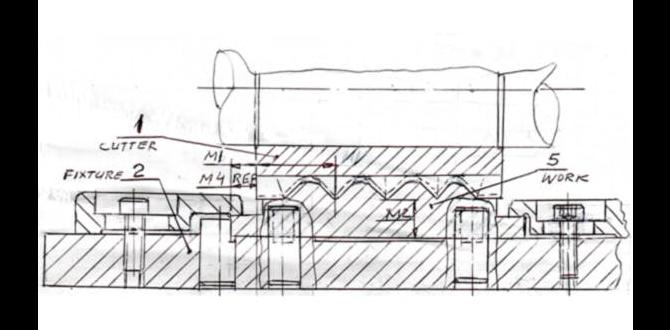

Stepbystep guide to inspecting the lathe setup. Tools required for inspection and diagnosis.To fix the lathe carriage not moving, start by checking the setup step-by-step. First, look for any visible obstructions. You don’t want your lathe having a tantrum over a tiny scrap! Next, use a wrench to check if all screws are tight. Loose screws can make things wobbly. Having the right tools is crucial. A simple checklist would include: measuring tape, wrench, and a flashlight to spot those sneaky issues!

| Tool | Purpose |

|---|---|

| Measuring Tape | Check for alignment |

| Wrench | Tighten screws |

| Flashlight | Spot hidden problems |

Remember, taking your time can lead to smooth sailing—or rather, smooth machining!

Common Issues and Their Solutions

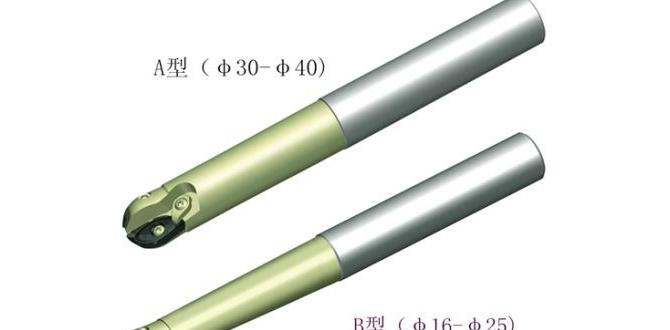

Gear or rack misalignment issues. Problems with the lead screw.Lathe machines can be tricky! If the carriage isn’t moving, it might be due to some common issues. First, check the gear or rack. If they’re misaligned, the carriage might decide to take a vacation. Tightening them can solve the problem. Next, look at the lead screw. If it’s damaged, the carriage won’t budge. Clean and lubricate it. If all else fails, get professional help. Your lathe’s home alone, and it needs a little TLC!

| Issue | Solution |

|---|---|

| Gear/Rack Misalignment | Tighten or realign components |

| Lead Screw Problems | Clean and lubricate or replace |

Checking for Obstructions and Debris

How to inspect for blockages. Methods for cleaning and maintaining moving parts.Sometimes, the carriage on your lathe doesn’t want to move, and that can feel like your pet cat ignoring you when you call! First, take a good look for any obstructions hiding in plain sight. Dust bunnies and grease can sneak around like ninjas. Use a flashlight to inspect the moving parts for any debris.

To keep things flowing smoothly, use a soft brush and some lubricant weekly. It’s like a spa day for your lathe—it deserves some pampering! Here’s a handy checklist to help you:

| Action | Frequency |

|---|---|

| Check for debris | Weekly |

| Clean moving parts | Monthly |

| Lubricate parts | Monthly |

Keeping your lathe clean is key to avoiding big headaches later! A tidy workspace is a happy workspace. So grab that brush and let’s get to cleaning!

Lubrication Techniques for Smooth Operation

Importance of lubrication in lathe machinery. Best lubricants to use and their application.Keeping your lathe running smoothly is much like giving your pet a good belly rub—lubrication is key! Proper lubrication prevents wear and tear, helping your lathe do its job without grumbling. Use light machine oil for smooth parts and grease for tougher spots. Each lubricant has its special place, much like how peanut butter belongs on toast, not pizza. Check the table below for the best lubricants and where to use them!

| Lubricant Type | Application |

|---|---|

| Light Machine Oil | For moving parts and bearings |

| Heavy Grease | For gears and heavy-duty sections |

| Wax-Based Lubricant | For fine finishes and protecting against rust |

When your lathe feels sluggish, don’t fret! A little oil or grease can work wonders. Remember, a well-lubricated lathe is a happy lathe!

When to Seek Professional Help

Indicators that a professional service may be necessary. Guidelines for choosing a qualified technician.If you notice strange sounds or a complete stop in the lathe, it may be time for help. Also, if parts look damaged or you can’t fix the issue after multiple tries, don’t hesitate to call a professional. Choosing the right technician is key. Look for:

- Experience – Check how long they’ve worked with lathes.

- Reviews – Read what other customers say.

- Certifications – Ensure they’re trained and qualified.

Getting help early can save time and money. It’s better to ask for help than to make things worse.

When should I call a technician?

If your lathe isn’t working and you’ve tried fixing it, it’s wise to seek help. Professionals can quickly find and fix problems.

Preventative Maintenance Tips for Longevity

Recommended routine maintenance practices. Key factors that contribute to carriage lifespan.Keeping your lathe carriage happy is like keeping a cat fed and purring. First, check the lubrication regularly. Dirty oil is like a flat tire; it won’t get you far! Clean the slides and adjust the belt tension so it doesn’t fling off in a fit of rage. Surprising fact: regular maintenance can extend the life of your lathe by up to 50%! Below is a quick checklist:

| Routine Maintenance Task | Frequency |

|---|---|

| Oil the carriage | Weekly |

| Clean the bed | Monthly |

| Check belt tension | Every 6 months |

Remember, a little care goes a long way. Treat your lathe like the valuable tool it is, and it will serve you well!

Conclusion

In summary, if your lathe carriage isn’t moving, check the power supply, lubricant, and for any obstructions. Regular maintenance can prevent these issues. You can also consult your user manual for specific advice. Don’t hesitate to reach out to experts if needed. With these steps, you can get your lathe working smoothly again. Happy machining!FAQs

What Are The Common Causes Of A Lathe Carriage Not Moving?If the lathe carriage isn’t moving, it could be stuck because something is blocking it. You might have dirt or debris in the way. Sometimes, the parts might be too tight or rusty. Check if the power is on and if everything is connected properly. Also, make sure the controls are in the right position.

How Can I Troubleshoot The Feed Mechanism On My Lathe If The Carriage Is Stuck?To troubleshoot the stuck carriage on your lathe, first, check for any visible obstacles. Look for chips or debris blocking the path. Next, make sure the feed lever is in the correct position. You can also try moving the carriage by hand gently. If it still won’t move, check the machine’s manual for more help.

What Maintenance Steps Can Prevent The Lathe Carriage From Becoming Immovable?To keep the lathe carriage moving smoothly, we should clean it often. Dust and dirt can make it stick. Next, we should check the oil level. Adding oil helps the moving parts slide easily. Finally, we can look for any loose screws and tighten them. This keeps everything in place and working well.

Are There Specific Adjustments That Need To Be Made If The Lathe Carriage Is Misaligned?Yes, we need to make some adjustments if the lathe carriage is misaligned. First, check the alignment using a ruler or straightedge. If it’s off, loosen the screws on the carriage. Then, gently move it into the right position. Finally, tighten the screws back up to keep it in place.

How Do I Safely Disassemble And Inspect The Carriage Assembly For Any Obstructions Or Damage?To safely take apart the carriage assembly, first, turn off and unplug the machine. Next, use a screwdriver to remove any screws holding it together. Be careful and keep track of the screws. Once it’s open, look for anything stuck or broken inside. If you see anything unusual, it’s best to ask an adult for help!