Have you ever watched a lathe in action? It’s fascinating how these machines shape wood and metal. One important part of the lathe is the carriage. The lathe carriage stop plays a key role in ensuring that workpieces are cut accurately.

But what makes a good lathe carriage stop design? Imagine trying to carve a perfect piece, but the tool keeps slipping. Frustrating, right? That’s why understanding this design is so important.

Many creators overlook the carriage stop, but it can make a big difference. A well-designed stop helps prevent errors and saves time. You might be surprised to learn that even small changes can lead to greater precision in your work.

In this article, we will explore various designs. We will also share tips on how to find the right one for your needs. So, are you ready to dive into the world of lathe carriage stops? Let’s get started!

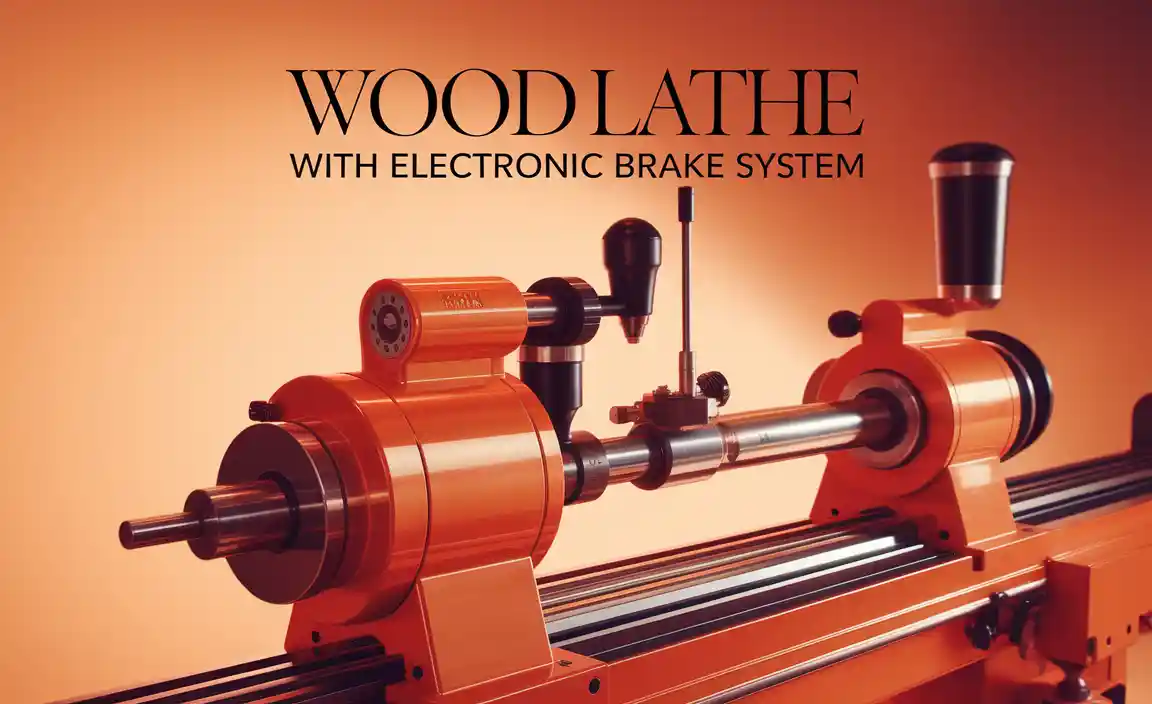

Lathe Carriage Stop Design: Essential Features And Functions

Lathe Carriage Stop Design

The lathe carriage stop is crucial for precise machining. It helps control the movement of the lathe’s carriage, ensuring accuracy in cuts. Did you know that a well-designed stop can improve your work efficiency? Different types of stops can be adjusted for various tasks. For example, some allow quick changes between short and long cuts. Understanding lathe carriage stop design can greatly enhance your projects. Don’t underestimate this small, yet powerful tool!Understanding the Purpose of a Carriage Stop

Explanation of carriage stops in lathe operations. Importance of precision in machining processes.A carriage stop is an important tool in lathe operations. It helps limit how far a tool moves on the workpiece. This ensures that cuts are precise and consistent. Precision is key in machining processes. It leads to high-quality work and reduces mistakes. A small error can cause bigger problems in final products. Using a carriage stop improves accuracy and saves time.

What is the role of a carriage stop in lathe operations?

A carriage stop guides the cutting tool, ensuring exact measurements and preventing overcutting.

Key benefits of carriage stops:

- Ensures accurate cuts

- Reduces material waste

- Increases efficiency

Types of Lathe Carriage Stops

Fixed vs. adjustable carriage stops. Advantages and disadvantages of each type.There are two main types of carriage stops: fixed and adjustable. Fixed stops stay in one spot and are simple to use, like a loyal dog that follows orders. However, they can limit your options. Adjustable stops are like a playful puppy; they can change positions for different tasks. They give you more versatility but can be a bit tricky to manage. Below is a table showing some pros and cons:

| Type | Advantages | Disadvantages |

|---|---|---|

| Fixed | Easy to set up, reliable | Limited adjustments |

| Adjustable | Flexible for various tasks | Can be complex to adjust |

Choosing the right type really depends on your needs. If you want simplicity, go for fixed. If versatility is your goal, adjustable is the way to go. Whether you’re fixed like a statue or adjustable like a yoga master, both types have their perks!

Key Design Considerations for Lathe Carriage Stops

Material selection for durability and performance. Dimensions and tolerances for optimal functionality.Choosing the right material for a lathe carriage stop is key for long-lasting use. Strong metals, like steel, are great for durability. They can handle wear and tear. It’s also important to get the dimensions just right. Correct tolerances ensure smooth operation. When everything fits well, the stop works better. This helps create better products, keeping both safety and quality in mind.

What materials are best for lathe carriage stops?

The best materials are steel and aluminum. They resist wearing down and provide strong support.

What dimensions matter for lathe carriage stops?

- Length: Should fit the lathe model.

- Width: Must allow smooth movement.

- Height: Needs to match the workpiece.

Step-by-Step Guide to Designing a Custom Carriage Stop

Necessary tools and materials for fabrication. Detailed design process: from concept to implementation.To create your custom carriage stop, you’ll need a few essential tools and materials. Gather things like a measuring tape, a saw, and some metal stock. Don’t forget safety goggles! Once you have everything, start planning your design on paper. Measure twice; cut once! This way, your stop will fit perfectly. Imagine the satisfaction of a project well done! Below is a basic table of what you’ll need:

| Tools | Materials |

|---|---|

| Measuring Tape | Metal Stock |

| Saw | Fasteners |

| Drill | Paint (optional) |

Now that you’ve got everything, sketch your design. Keep it simple and clear. Make adjustments as needed to ensure it works well. Testing is key! Once you’re happy, it’s time to put that plan into action. Install your new stop and watch how smooth your work becomes. It’s like magic—only with tools!

Implementing the Carriage Stop in Lathe Operations

Best practices for installing the carriage stop. Common challenges and how to overcome them.Installing the carriage stop on a lathe is a simple but important task. Here are some best practices to follow:

- Clean the lathe area before starting.

- Align the carriage stop carefully with the workpiece.

- Use the right tools for the installation.

- Test the stop regularly during use.

Common challenges include misalignment and difficulty in adjustment. To overcome these issues, double-check your measurements and adjust the stop slowly. A little patience goes a long way in achieving perfect results.

How can I ensure proper installation of the carriage stop?

Always **double-check your measurements** before tightening the carriage stop. This helps avoid mistakes and ensures accuracy while working. Remember, a well-installed stop improves your lathe’s performance!

Comparative Analysis of Commercially Available Carriage Stops

Key features of top products on the market. Price comparison and value assessment.Many carriage stops in the market have special features. Some popular ones include easy adjustment, solid build, and compatibility with different lathes. Prices vary greatly. Here’s a quick look:

- Basic model: $20 – Good for beginners.

- Mid-range model: $50 – Offers more durability and features.

- Premium model: $100 – Best quality and advanced options.

Choosing the right one depends on your needs and budget. Be sure to find a carriage stop that gives good value for your money.

What should I look for in a good carriage stop?

Look for adjustability, durability, and compatibility with your lathe for the best performance.

Testing and Calibration of Carriage Stops

Methods to ensure accuracy after installation. Importance of regular maintenance and adjustments.After you install carriage stops, it’s crucial to test and calibrate them. This ensures they work correctly for precise cuts. To check accuracy, you can:

- Use a measuring tool to verify distances.

- Make a few test cuts on scrap material.

- Adjust settings based on results.

Regular maintenance keeps your carriage stops in top shape. Small adjustments can help them function better. Poorly maintained stops can lead to mistakes. Always check and adjust them to avoid problems.

Why is regular maintenance important?

Regular maintenance prevents wear and tear. It saves you time and helps achieve better results.

User Experiences and Feedback

Testimonials from machinists and engineers. Case studies showcasing the effectiveness of various designs.Many machinists and engineers share strong opinions about the lathe carriage stop design. Their experiences help improve tools. For instance, one machinist reported, “This stop makes my work easier and faster.” Another added, “It’s accurate and simple to adjust.” Case studies show that better designs reduce mistakes and save time. Effective designs clearly lead to satisfied users.

What do users say about lathe carriage stops?

Users love the simplicity and efficiency of various designs. Feedback often includes:

- Improved accuracy

- Less downtime

- Easy adjustments

Such testimonials showcase the positive impact on everyday work. Designers and makers can learn a lot from this feedback.

Future Trends in Lathe Carriage Stop Technology

Innovations in materials and design techniques. The role of digital technology and automation in carriage stops.New ideas are changing lathe carriage stops. Lightweight materials make them easier to use. Design techniques focus on simplicity and speed. Digital technology allows for smart carriage stops. They can adjust with just a touch! Automation makes these stops quick and reliable.

- More durable materials

- Easy-to-use digital controls

- Faster operations due to automation

What are some recent innovations in lathe carriage stop technology?

Recent changes are exciting! Stronger materials and smart designs make work faster and safer. Also, digital controls help users operate them with ease.

Conclusion

In summary, a lathe carriage stop design helps you control your cuts accurately. It makes your work easier and more precise. Remember to choose materials that suit your needs. Experiment with different designs to find what works best for you. For more ideas and tips, check out additional resources or talk to experienced machinists. Happy machining!FAQs

Certainly! Here Are Five Questions Related To Lathe Carriage Stop Design:Sure! A lathe carriage stop helps you control how far the tool moves on a lathe machine. It makes sure the tool cuts at the right spot every time. You can set it to stop at different places for different tasks. This helps you work faster and more accurately! Would you like to know how to use it?

Sure! Just let me know the question you want me to answer, and I’ll help you with a simple response.

What Are The Essential Features That A Lathe Carriage Stop Should Have To Ensure Accurate And Repeatable Machining Operations?A lathe carriage stop should be easy to use. It needs to move smoothly so you can lock it in place. You want it to be strong, so it doesn’t slip during work. It should also be adjustable to let you set different lengths easily. This way, you can repeat your cuts perfectly every time.

How Does The Material Choice For A Lathe Carriage Stop Impact Its Durability And Performance In A Machining Environment?The material you choose for a lathe carriage stop affects how long it lasts and how well it works. If you use strong materials like steel, it won’t break or wear out easily. A durable stop helps the machine run better and makes your work more accurate. But if you pick a weak material, it can break quickly and cause problems. So, using the right material is very important!

What Are The Differences Between Adjustable And Fixed Lathe Carriage Stops, And In Which Scenarios Is Each Type Preferred?Adjustable lathe carriage stops can change their position easily. This helps you make different cuts without changing the tool. Fixed lathe carriage stops stay in one place and are good for making the same cuts over and over. You should use adjustable stops for different tasks, and fixed stops for repeated jobs.

How Can The Design Of A Lathe Carriage Stop Be Optimized To Facilitate Quick Setup Changes While Maintaining Precision?To make the lathe carriage stop easier to use, we can use simple knobs and levers. These make it quick to adjust without needing tools. We can also add clear markings so you can see where to set it. Using strong materials helps keep everything precise. This way, you can change setups fast and still make accurate parts.

What Safety Considerations Should Be Taken Into Account When Designing And Implementing A Lathe Carriage Stop?When designing a lathe carriage stop, we need to think about a few safety rules. First, we should make sure the stop is easy to see and use. This helps prevent accidents. Next, the stop should be strong and not break easily during use. Finally, we need to teach everyone how to use the lathe safely to reduce risks.