Imagine working in a workshop filled with buzzing machines and the smell of metal. Among these busy tools, the lathe stands out. It’s amazing how much a lathe can do. But have you ever thought about how to measure the carriage travel of a lathe? This skill is key to making precise parts.

Measuring carriage travel might sound tricky, but it’s essential for any machinist. It helps ensure that your cuts are exact and that your workpiece is just right. Have you ever felt frustrated when a tool doesn’t line up correctly? Proper measurements can save you from those headaches.

In this article, we will explore the importance of lathe carriage travel measurement. We’ll also share tips to help you get it right. Whether you’re a beginner or an experienced machinist, understanding this process can improve your work. So, let’s dive into the world of lathe carriage travel and discover its secrets together!

Lathe Carriage Travel Measurement: A Comprehensive Guide

Lathe Carriage Travel Measurement Explained

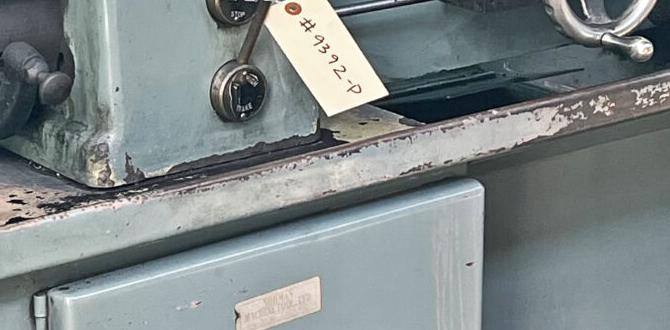

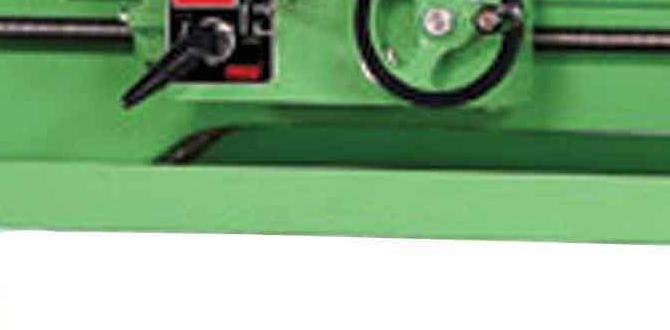

Lathe carriage travel measurement is essential for accurate machining. It allows users to know how far the carriage moves along the lathe bed. Proper measurement helps achieve precision in cuts and shapes. Imagine trying to carve your favorite design without knowing if your lathe is set right! By understanding how to measure travel accurately, you can avoid mistakes and enhance your skills. Did you know that even small miscalculations can lead to big errors in your projects?What is Lathe Carriage Travel?

Definition and importance in machining. How carriage travel affects precision and accuracy.Carriage travel on a lathe is how far the cutting tool moves along the workpiece. This distance is key because it directly impacts the precision and accuracy of the machining process. Picture trying to bake a cake without measuring the ingredients—yikes! If the carriage doesn’t travel right, your final product can end up being lopsided. A well-measured travel ensures smooth and even cuts, crucial for high-quality results.

| Key Point | Impact |

|---|---|

| Define Carriage Travel | Affects machining quality |

| Importance of Accuracy | Ensures perfect fit |

Components Involved in Carriage Travel Measurement

Description of key parts (carriage, leadscrew, etc.). Role of each component in the measurement process.Lathe carriage travel measurement is all about teamwork among key parts. The carriage holds the cutting tool and moves it along the workpiece. The leadscrew is like the backbone, guiding the carriage with precision. The handwheel helps adjust the position. Each component works together like a well-trained band. Without the leadscrew, the carriage might just dance around, and that wouldn’t cut it!

| Component | Role |

|---|---|

| Carriage | Moves the cutting tool along the workpiece. |

| Leadscrew | Guides the movement of the carriage. |

| Handwheel | Adjusts the carriage’s position accurately. |

Calibration of Measurement Tools

Importance of calibration for accuracy. Stepbystep process for calibrating measuring tools.Keeping measuring tools in check is essential for getting things right. Without proper calibration, even the best tools can go off the rails, leading to mistakes that can cost time and money. Luckily, calibrating your measuring tools is a breeze! Start by checking the device against a standard reference. Record any differences. Adjust the tool, and check again until it matches. Voilà! Your tools are now ready to perform like pros. Remember, a happy tool makes for a happy craftsman!

| Step | Description |

|---|---|

| 1 | Check against a known standard |

| 2 | Note any differences |

| 3 | Adjust the tool |

| 4 | Re-check until accurate |

Common Challenges in Carriage Travel Measurement

Typical issues (slippage, wear and tear). Solutions and best practices to mitigate these problems.Measuring the travel of a lathe carriage comes with its quirks. Slippage can make readings wild, like trying to catch a greased pig! Wear and tear on parts adds to the problem, making accuracy a bit tricky.

To tackle these pesky issues, regular maintenance is key. Keeping everything clean and well-lubricated helps a lot. Using quality components can also solve these problems by reducing wear. Preventive care is where the magic happens!

| Common Issues | Solutions |

|---|---|

| Slippage | Regular adjustments |

| Wear and Tear | Use high-quality parts |

Remember, a happy lathe means less headache!

Impact of Carriage Travel on Machining Operations

Influence on part quality and production efficiency. Case studies or examples of successful measurement impacts.The distance a lathe carriage travels can make a big difference in how well parts are made. If the travel is measured correctly, it can lead to better quality and faster production. For instance, in one case, a factory improved its output by 30% simply by refining its carriage travel measurement. That’s like finding a hidden ice cream stash! Proper measurement means fewer mistakes and more happy customers. It’s like measuring twice so you can cut once. Everybody loves saving time, right?

| Benefit of Proper Measurement | Example Impact |

|---|---|

| Improved Part Quality | Reduced errors by 15% |

| Increased Production Efficiency | Boosted output by 30% |

Tips for Accurate Carriage Travel Measurement

Best practices for machinists and technicians. Maintenance recommendations to ensure longevity and accuracy.To measure carriage travel accurately, follow these best practices: Ensure the lathe is clean and free from debris. A clean workspace improves accuracy and efficiency. Regularly check the setting of the dial indicators, as they may drift over time. This provides precise readings. Use a reliable standard gauge for calibration as it helps maintain consistent results.

For maintenance, consider these tips:

- Lubricate moving parts every month.

- Inspect the carriage for wear regularly.

- Keep the lathe bed free from rust.

These steps help extend the life of your lathe and ensure accurate measurements every time.

Why is regular lathe maintenance important?

Regular maintenance ensures long-lasting performance and accuracy in measurements. It prevents small issues from growing into bigger problems.

Conclusion

In summary, measuring lathe carriage travel is crucial for accurate machining. It helps us keep our work precise and efficient. You can use calipers or measuring tapes for this task. Understanding these measurements can improve your skills. We encourage you to practice measuring on your own lathe and explore more resources to enhance your learning. Keep experimenting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Carriage Travel Measurement:Sure! When we measure the lathe carriage travel, we want to see how far the carriage can move. The carriage is the part that holds the tool. You can use special tools to check this distance accurately. It helps us make sure our work on the lathe is correct and safe. This way, you get better results in your projects!

Sure! Please provide the question you want answered, and I’ll help you with that.

What Are The Common Methods Used For Measuring The Travel Distance Of A Lathe Carriage?We can measure the travel distance of a lathe carriage in a few ways. One way is to use a ruler or tape measure. You can also use a dial indicator, which shows how far the carriage moves. Some people use digital readouts that show the distance on a screen. Each method helps us know how far the carriage has traveled.

How Does The Accuracy Of Carriage Travel Measurement Affect Machining Precision?When we measure how far a machine moves, it needs to be very accurate. If it isn’t, the parts we make can end up the wrong size. This means pieces might not fit together or work right. So, paying attention to these measurements helps us make better and more precise parts. It’s like drawing a straight line; if your ruler isn’t exact, your line will be crooked!

What Tools And Instruments Are Recommended For Enhancing The Measurement Of Lathe Carriage Travel?To measure how far the lathe carriage moves, you can use a few tools. A digital caliper helps you see exact distances easily. A dial indicator shows small movements accurately. A ruler or measuring tape can also be handy for quick checks. These tools will make your measurements clearer and help you work better!

How Can Improper Measurement Of Lathe Carriage Travel Lead To Machining Errors Or Defects?If you don’t measure the lathe carriage travel correctly, you might cut too much or too little from the piece you’re working on. This can create parts that don’t fit together well. You could also make mistakes in shapes or sizes that shouldn’t be there. So, it’s important to measure accurately to avoid these problems!

What Are The Maintenance Considerations To Ensure Accurate Lathe Carriage Travel Measurements Over Time?To keep the lathe working well, we should check it regularly. Make sure the carriage is clean and free of dirt. Lubricate, or oil, the moving parts to help them slide easily. Check the belts and screws to see if they are tight. If anything seems worn out, replace it to keep everything accurate.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Carriage Travel Measurement:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When we measure the lathe carriage travel, we want to see how far the carriage can move. The carriage is the part that holds the tool. You can use special tools to check this distance accurately. It helps us make sure our work on the lathe is correct and safe. This way, you get better results in your projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want answered, and I’ll help you with that.”}},{“@type”: “Question”,”name”: “What Are The Common Methods Used For Measuring The Travel Distance Of A Lathe Carriage?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can measure the travel distance of a lathe carriage in a few ways. One way is to use a ruler or tape measure. You can also use a dial indicator, which shows how far the carriage moves. Some people use digital readouts that show the distance on a screen. Each method helps us know how far the carriage has traveled.”}},{“@type”: “Question”,”name”: “How Does The Accuracy Of Carriage Travel Measurement Affect Machining Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we measure how far a machine moves, it needs to be very accurate. If it isn’t, the parts we make can end up the wrong size. This means pieces might not fit together or work right. So, paying attention to these measurements helps us make better and more precise parts. It’s like drawing a straight line; if your ruler isn’t exact, your line will be crooked!”}},{“@type”: “Question”,”name”: “What Tools And Instruments Are Recommended For Enhancing The Measurement Of Lathe Carriage Travel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure how far the lathe carriage moves, you can use a few tools. A digital caliper helps you see exact distances easily. A dial indicator shows small movements accurately. A ruler or measuring tape can also be handy for quick checks. These tools will make your measurements clearer and help you work better!”}},{“@type”: “Question”,”name”: “How Can Improper Measurement Of Lathe Carriage Travel Lead To Machining Errors Or Defects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t measure the lathe carriage travel correctly, you might cut too much or too little from the piece you’re working on. This can create parts that don’t fit together well. You could also make mistakes in shapes or sizes that shouldn’t be there. So, it’s important to measure accurately to avoid these problems!”}},{“@type”: “Question”,”name”: “What Are The Maintenance Considerations To Ensure Accurate Lathe Carriage Travel Measurements Over Time?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lathe working well, we should check it regularly. Make sure the carriage is clean and free of dirt. Lubricate, or oil, the moving parts to help them slide easily. Check the belts and screws to see if they are tight. If anything seems worn out, replace it to keep everything accurate.”}}]}