Imagine you have a cool machine that spins a piece of wood or metal. It’s called a lathe. But did you know that getting the height just right is super important? This is where lathe center height calculation comes in. If the center isn’t perfect, your projects can go wrong.

This measurement helps you create nice smooth shapes. Without it, your work could wobble or even break. Have you ever seen a wobbly table leg? That’s a perfect example of what can happen if the center height is off!

In this article, we will discover how to calculate the lathe center height correctly. You’ll learn simple steps to make your projects come out just right. Ready to dive in and become a lathe expert? Let’s explore together!

Lathe Center Height Calculation: Essential Techniques & Tips

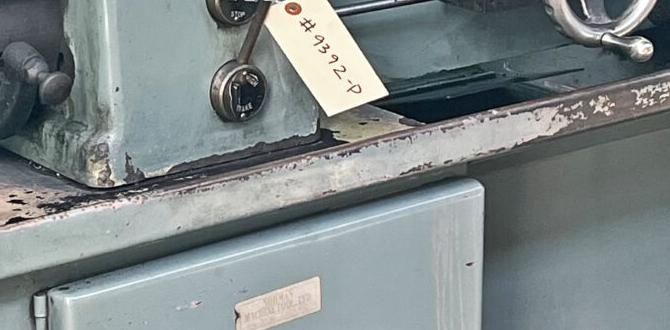

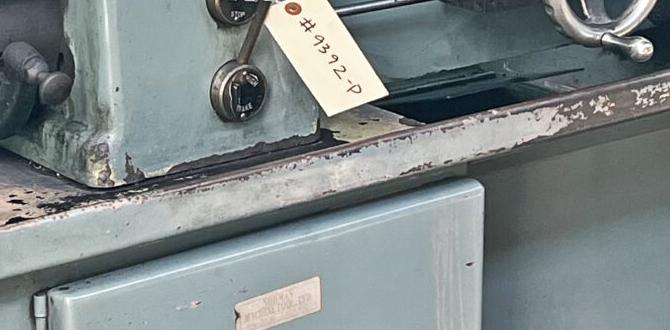

Lathe Center Height Calculation

Lathe center height calculation is essential for accurate machining. Understanding this concept helps ensure that the cutting tool aligns perfectly with the workpiece. Did you know that an incorrect center height can lead to poor cuts or even tool breakage? To find the right height, measure the distance from the spindle axis to the lathe bed. This simple calculation can save you time and materials in your projects. Ensure your lathe setup is spot on for successful turning operations!Understanding Center Height in Lathe Operations

Definition of center height and its significance in lathe work. Effects of incorrect center height on machining precision and quality.Center height is where the lathe tool meets the workpiece’s center. It matters because if the height is off, your cuts can become wobbly—kind of like a toddler on roller skates! An incorrect center height can lead to poor machining precision, making everything wonky. This might cause uneven surfaces or even break your tools. Keep it right for high-quality results, or you might end up with a lopsided pizza instead of a perfect wheel!

| Center Height Accuracy | Effects of Incorrect Height |

|---|---|

| Precise Cuts | Wobbly Edges |

| Quality Finish | Uneven Surfaces |

| Tool Longevity | Possible Breakage |

Methods for Calculating Lathe Center Height

Stepbystep guide to traditional calculation methods. Utilizing measuring tools for accurate center height determination.Finding the center height on a lathe is like measuring your height for a roller coaster ride—accuracy matters! First, you can use a simple ruler to check the tailstock or headstock height to find the center line. Next, tools like calipers are great for more exact measurements. Remember, even a small mistake can lead your work to look like a wobbly wheel! Here’s a quick guide in a table:

| Method | Description |

|---|---|

| Ruler Method | Use a ruler to measure from the base to the center point on the lathe. |

| Caliper Method | Attach calipers to the lathe and measure carefully for precision. |

By using these methods, you’ll get a very clear picture of where the center is. Happy turning and may your designs stay balanced!

Practical Examples of Center Height Calculation

Realworld scenarios demonstrating center height calculation techniques. Comparisons between manual calculation and using software tools.Center height calculation plays an important role in various fields, like manufacturing. Here are some practical examples:

- Joining two parts at the right height for stability.

- Making shafts in machines that rotate smoothly.

Manual calculations take time. However, using software tools can speed up the process. These tools provide quicker and more accurate results, which helps avoid mistakes. In fact, studies show that software can reduce calculation time by up to 50%. It’s often better to use technology!

What are real-life examples of using center height calculation?

Center height calculation is useful in projects like building furniture or assembling machines. These tasks require precision to ensure everything fits correctly.

How are manual calculations different from software tools?

- manual calculations require more time and focus.

- Software tools offer speed and less chance of errors.

Common Mistakes in Center Height Calculation

Identification of typical errors made by machinists. Consequences of these mistakes and prevention strategies.Machinists often trip over the same common errors in height calculation. Not aligning the workpiece correctly can lead to skewed cuts. Skipping the measurement of the lathe’s center height is like trying to bake cookies without flour—hardly any fun! The results can be disastrous, leading to wasted materials and time.

To avoid these blunders, always double-check your measurements. Here’s a handy table for quick reference:

| Error | Consequence | Prevention Strategy |

|---|---|---|

| Misalignment of the workpiece | Skewed cuts | Check alignment before starting |

| Ignoring center height | Wasted material | Always measure and adjust |

| Incorrect tool height | Poor surface finish | Use a height gauge |

By following these simple tips, you can avoid headaches and joyfully create without mishaps!

Tools and Resources for Accurate Center Height Measurement

List of tools suitable for measuring center height. Recommendations for software and online calculators available for machinists.To measure center height accurately, use reliable tools. Here are some helpful options:

- Measuring tape

- Calipers

- Micrometers

- Height gauges

- Dial indicators

For added convenience, consider using software for calculations. Many machinists find online calculators useful. These tools save time and ensure precision.

What tools are best for measuring center height?

Good tools include calipers and height gauges for accurate measurements.

What software can help with calculations?

- Online lathe calculators

- Machining simulation software

- CAD programs with measurement functions

These resources make it easier to calculate center height. Accurate measures lead to better work quality. Happy machining!

Best Practices for Maintaining Proper Center Height

Tips for ensuring consistent center height during operations. Routine checks and maintenance procedures for lathe setups.Keeping the center height right is like ensuring your cake doesn’t collapse. Regular checks can help! First, use a simple ruler to measure height before you start. If your cake’s too tall, you might just have a disaster. Routine maintenance is also key. Clear debris and check tool settings often. Don’t forget to tighten those screws—loose screws are like shaky tables at a dinner party! To keep things extra organized, use this quick checklist:

| Routine Checks | Frequency |

|---|---|

| Measure center height | Before each use |

| Clean workspace | After each session |

| Tighten screws | Weekly |

With these tips, your lathe will work smoothly, and you’ll avoid any surprises. No one likes surprises, unless they’re cake!

Conclusion

In summary, calculating lathe center height is important for accurate machining. You need to measure the workpiece carefully. Adjust your lathe accordingly to ensure precision. Remember, a well-set center height leads to better results. Explore more about lathe setups and practice these calculations. By doing so, you’ll improve your skills and confidence in using a lathe!FAQs

Here Are Five Related Questions On The Topic Of Lathe Center Height Calculation:Sure! To find the center height for a lathe, you measure from the floor to the center of the lathe’s spindle. You then compare this to the size of the tool you plan to use. If your tool is too high or too low, it won’t cut properly. So, you want to make sure they match to do a good job. This makes your work safer and easier!

Sure! Just give me the question you have in mind, and I’ll provide a clear and simple answer.

What Is The Significance Of The Center Height In Lathe Operations, And How Does It Affect Workpiece Accuracy?The center height in lathe operations is how high the tool is from the lathe bed. It is important because it helps the tool cut the workpiece evenly. If the height is wrong, the cuts can be uneven, making the workpiece less accurate. So, keeping the correct center height helps you make better and smoother shapes. This way, your projects will turn out just right!

How Do You Calculate The Proper Center Height For Different Lathe Configurations And Workpieces?To find the right center height for your lathe, first measure the diameter of your workpiece. Then, divide that number by two to get the radius. Next, add this radius to the height of the lathe’s center from the ground. This helps ensure the workpiece spins smoothly and can be shaped correctly.

What Are The Common Methods Used To Set And Adjust The Center Height On A Lathe?To set the center height on a lathe, we can use a tool called a center finder. You place the center finder on the lathe’s bed and adjust it until the tip is right in the middle. Another method is to use a level. You can check it with a small level to make sure it’s straight. Finally, you can adjust the height by changing the position of the tailstock.

How Does The Center Height Impact The Tool Path And Finish Quality During Machining Processes?The center height is where the tool sits compared to the piece we are working on. If the center height is just right, the tool moves smoothly. This helps create a clean finish on the surface. If the height is wrong, the tool can bump or drag, making the finish rough. So, we need to check the center height for better results!

What Tools Or Equipment Can Be Used To Measure And Verify The Center Height On A Lathe Accurately?To measure and verify the center height on a lathe, you can use a few simple tools. A center gauge helps you check the height quickly. You can also use a dial gauge, which shows precise measurements. A height gauge is another option that gives you accurate readings. These tools help make sure everything is set up correctly for your work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Center Height Calculation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! To find the center height for a lathe, you measure from the floor to the center of the lathe’s spindle. You then compare this to the size of the tool you plan to use. If your tool is too high or too low, it won’t cut properly. So, you want to make sure they match to do a good job. This makes your work safer and easier!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you have in mind, and I’ll provide a clear and simple answer.”}},{“@type”: “Question”,”name”: “What Is The Significance Of The Center Height In Lathe Operations, And How Does It Affect Workpiece Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The center height in lathe operations is how high the tool is from the lathe bed. It is important because it helps the tool cut the workpiece evenly. If the height is wrong, the cuts can be uneven, making the workpiece less accurate. So, keeping the correct center height helps you make better and smoother shapes. This way, your projects will turn out just right!”}},{“@type”: “Question”,”name”: “How Do You Calculate The Proper Center Height For Different Lathe Configurations And Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right center height for your lathe, first measure the diameter of your workpiece. Then, divide that number by two to get the radius. Next, add this radius to the height of the lathe’s center from the ground. This helps ensure the workpiece spins smoothly and can be shaped correctly.”}},{“@type”: “Question”,”name”: “What Are The Common Methods Used To Set And Adjust The Center Height On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set the center height on a lathe, we can use a tool called a center finder. You place the center finder on the lathe’s bed and adjust it until the tip is right in the middle. Another method is to use a level. You can check it with a small level to make sure it’s straight. Finally, you can adjust the height by changing the position of the tailstock.”}},{“@type”: “Question”,”name”: “How Does The Center Height Impact The Tool Path And Finish Quality During Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The center height is where the tool sits compared to the piece we are working on. If the center height is just right, the tool moves smoothly. This helps create a clean finish on the surface. If the height is wrong, the tool can bump or drag, making the finish rough. So, we need to check the center height for better results!”}},{“@type”: “Question”,”name”: “What Tools Or Equipment Can Be Used To Measure And Verify The Center Height On A Lathe Accurately?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure and verify the center height on a lathe, you can use a few simple tools. A center gauge helps you check the height quickly. You can also use a dial gauge, which shows precise measurements. A height gauge is another option that gives you accurate readings. These tools help make sure everything is set up correctly for your work.”}}]}