Have you ever watched a lathe in action? It spins and carves, creating beautiful pieces of wood or metal. But what happens to all those tiny chips that fly off? They can be messy! That’s where a lathe chip tray design plan comes into play.

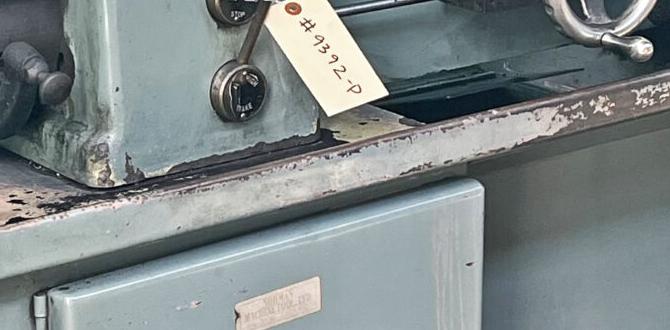

Imagine walking into a workshop. You see a lathe at work, cutting cleanly through material. Beside it, there’s a neat chip tray catching all those shavings. How satisfying it is to see everything tidy! With a thoughtful chip tray design, you gain both cleanliness and efficiency.

Many people may not think about this important piece of equipment. A good chip tray saves time and energy. Plus, it helps keep the workspace safe and organized. Did you know that a well-planned chip tray can even improve your lathe’s performance? It’s true! So, let’s dive into how you can create the perfect lathe chip tray design plan for your projects.

Lathe Chip Tray Design Plan: Essential Tips And Ideas

Lathe Chip Tray Design Plan

Creating a lathe chip tray design plan can make your workspace neat and tidy. Chip trays catch the debris from machining, preventing mess and promoting safety. Did you know a well-designed tray can save time on clean-up? When planning your tray, consider size, material, and how it will attach to the lathe. You’ll want something that’s easy to empty and durable enough for daily use. A little effort in planning goes a long way in keeping your area organized!Understanding the Importance of a Chip Tray

Explanation of chip tray functionality in lathe operations. Benefits of having an effective chip disposal system.A chip tray is key in lathe operations. It collects metal shavings and debris as the machine works. This keeps the workspace clean and safe. Without a good chip tray, chips can cause accidents and damage. An effective disposal system helps maintain the machine, prolonging its life. Here are some important benefits:

- Improved Safety: Less clutter means fewer trip hazards.

- Better Efficiency: A clean workspace boosts productivity.

- Easy Maintenance: Quick cleaning keeps machines running smoothly.

What does a chip tray do?

A chip tray collects and stores debris from the lathe. It protects the machine and workspace. Having one helps in keeping tools clear and ensures a smoother operation.

Essential Design Considerations

Key design features to enhance performance and ease of use. Importance of size and shape tailored to lathe specifications.Designing a lathe chip tray needs some thought. Start by thinking about size. A tray that’s too small may overflow, while one that’s too big could take up extra space. Performance matters too! A well-shaped tray helps catch every little chip. Also, consider how easy it is to clean. No one wants to dig around for the last stubborn bit! Remember, a smart design keeps your workspace tidy and your mind happy.

| Design Feature | Importance |

|---|---|

| Size | Must fit lathe perfectly! |

| Shape | Helps catch all chips! |

| Ease of Cleaning | Saves time and effort! |

Step-by-Step Guide to Creating a Chip Tray

Detailed instructions on measuring and cutting materials. Assembly process and necessary hardware.Making a chip tray is simple. First, measure your lathe’s base. Use a tape measure for accuracy. Cut materials with a saw according to your measurements. Assemble your tray using screws. Ensure each piece fits snugly. Here’s what you’ll need:

- Wood or metal for the tray

- Screws or bolts for assembly

- Drill for making holes

- Sandpaper for smoothing edges

By following these steps, you’ll create a sturdy chip tray that helps keep your workspace clean.

What materials do you need to make a chip tray?

You’ll need wood or metal, screws, a drill, and sandpaper. These items ensure your chip tray is strong and well-made.

Innovative Features to Integrate

Options for drainage systems and filtration. Ideas for custom attachments and modifications.Creating a smart lathe chip tray design plan can help improve your workspace. Some cool ideas to think about include:

- Drainage systems: Adding a drain can make cleaning easier. It helps remove waste quickly.

- Filtration options: Filters can catch tiny metal pieces. This keeps your workspace clean.

- Custom attachments: Consider brackets for tools. These can help save space and keep things organized.

- Modifications: Think about adjustable heights for trays. This allows you to fit different machines.

These features can make your lathe chip tray more useful and tidy.

What are some effective drainage system options?

Simple and effective drainage systems include using funnels or pipe systems. They help to direct liquids away from the tray easily. This keeps things neat and prevents spills.

What custom attachments are helpful?

- Magnetic strips for easy tool access.

- Holders for oil bottles and brushes.

- Hook attachments for cables and cords.

Maintenance Tips for Longevity

Best practices for maintaining cleanliness and functionality. Common issues and solutions for chip trays.Keeping your lathe chip tray clean is key to its long life. Regular cleaning helps it work well. Here are some simple tips:

- Wipe the tray after each use.

- Check for rust or cracks regularly.

- Remove chips quickly to avoid build-up.

Common problems include tray overflow and stuck chips. If the tray overflows, empty it more often. For stuck chips, try using a brush to loosen them up. Following these steps ensures your tray stays functional and durable!

What are common issues with chip trays?

Chip overflow and stuck debris are common issues.

How to solve these problems?

- Empty the chip tray regularly.

- Use a soft brush to clean stubborn debris.

Examples of Effective Chip Tray Designs

Showcase of various designs from different lathe users. Analysis of design effectiveness and user feedback.Lathe users have shared some clever chip tray designs that work wonders. For example, some users have curved edges to prevent chips from spilling out. Others prefer removable trays for easy cleaning. Feedback shows that simple designs often perform best. A happy user once declared, “My chips aren’t sneaky anymore!” Check out the table below for popular designs and their effectiveness.

| Design Type | Effectiveness | User Feedback |

|---|---|---|

| Curved Edges | High | “No more chips on the floor!” |

| Removable Tray | Medium | “Cleaning is a breeze!” |

| Magnetic Base | High | “Stays put while I work!” |

Frequently Asked Questions

Answers to common queries regarding chip tray usage and design. Discussion of best practices and user experiences.| Question | Answer |

|---|---|

| What is a chip tray? | A chip tray collects shavings and debris from a lathe. |

| How often should I empty it? | Empty it regularly, especially if it starts looking like a mini mountain! |

| Can I design my own? | Of course! Let your creativity flow, like those chips! |

Many people wonder how to keep their workspace tidy with a lathe chip tray. The best practice is to make sure you clean it frequently to avoid clogs. Users often share that a tray with proper drainage is vital. Don’t be shy to experiment; a unique design can work wonders! After all, every tray is a chance to express your inner artist, even if it’s just to keep the mess at bay.

Conclusion

In summary, a lathe chip tray design plan helps keep your workspace clean. It directs chips away from the lathe, improving safety. When designing yours, consider size, material, and drainage. You can find more tips online or in books about metalworking. By following these steps, you’ll create a useful tool for your projects. Let’s get started on your design today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Chip Tray Design Plans:Sure! Here are some ideas for designing a lathe chip tray. First, think about how big the tray needs to be. You want it to catch all the small pieces that fall while you work. Next, make sure it is easy to clean. You can use smooth materials that don’t hold onto dirt. Lastly, design it so it fits well with your lathe machine. This will help keep your workspace neat!

Sure! Please provide the question you would like me to answer.

What Materials Are Most Suitable For Constructing A Durable And Effective Lathe Chip Tray?You can use metal, plastic, or fiberglass for a strong lathe chip tray. Metal is tough and lasts long. Plastic is lighter and easier to clean. Fiberglass is strong and won’t rust. Choose the one that fits your needs best!

How Can The Design Of A Lathe Chip Tray Be Optimized For Easy Clean-Up And Maintenance?To make a lathe chip tray easy to clean, you can design it with smooth surfaces. This helps dirt and chips slide out easily. You should also add a drain at the bottom, so liquid can flow out quickly. It’s helpful if the tray can be removed, too. That way, you can take it outside to clean.

What Dimensions Should Be Considered When Designing A Chip Tray To Fit Various Lathe Models?When designing a chip tray for lathe machines, we need to think about size, shape, and how deep it is. First, measure the width and length of different lathe models. Next, consider the height to make sure it holds all the metal shavings. We should also ensure it fits snugly under the lathe so it doesn’t fall out. Finally, allow space for easy cleaning and emptying the tray.

How Can A Lathe Chip Tray Be Integrated With Existing Workshop Drainage Or Waste Management Systems?You can connect the lathe chip tray to your workshop’s drainage system. First, you’ll need a pipe that leads from the tray to the drain. When you use the lathe, chips and fluids will flow into the tray and then down the pipe. This keeps your workspace clean and makes it easier to manage waste. Always check that the connections are tight to avoid spills!

What Features Can Be Included In A Lathe Chip Tray Design To Prevent Chips From Spilling Onto The Workshop Floor?A lathe chip tray can have tall sides to keep chips inside. You can add slanted walls that guide chips to a center point. Making the bottom smooth helps chips slide easily into a bin. A lid or cover can stop chips from flying out when the machine is running. These features help keep your workshop clean and safe!