Have you ever wondered how machines like lathes work? They create amazing things from simple blocks of metal. One key part of making them more precise is the CNC encoder. Installing a CNC encoder on a lathe can change the game for any workshop.

Imagine this: you want to make a perfect screw or a smooth rod. Without a CNC encoder, it can be tricky. But once it’s installed, your lathe can measure movements accurately. Why does this matter? It helps create parts with tight tolerances, ensuring they fit perfectly.

But how do you go about installing one? It might seem tough, but it’s easier than you think. Follow the right steps, and you’ll master it in no time. This article will guide you through the process step-by-step. You’ll be impressing friends and colleagues with your newfound skills soon!

Lathe Cnc Encoder Installation: A Step-By-Step Guide

Lathe CNC Encoder Installation

Installing a lathe CNC encoder is crucial for precision in machining. This device helps the machine understand its position correctly. Without it, you might face errors during operations, leading to costly mistakes. Imagine trying to build with blocks but not knowing where to place each piece! Proper installation involves careful alignment and wiring. Learn about the steps to ensure your lathe runs smoothly. A well-installed encoder keeps your projects on track and boosts your productivity!Understanding CNC Encoders

Definition and purpose of CNC encoders in lathe operations. Types of encoders used in CNC systems.CNC encoders are important tools in lathe machines. They help measure movement very accurately. This helps the machine make precise cuts and shapes. There are different types of encoders used in CNC systems:

- **Incremental Encoders**: They track motion changes effectively.

- **Absolute Encoders**: These give a precise position without needing a reference point.

Both types ensure that lathe operations work smoothly and correctly.

What is the main purpose of CNC encoders?

The main purpose of CNC encoders is to enhance precision in machine operations. They ensure that every cut is exact and reduces the chance of errors.

Benefits of Installing CNC Encoders on Lathes

Improved accuracy and precision in machining. Enhanced control over the lathe functions.Installing CNC encoders on lathes brings awesome benefits! First, it significantly boosts accuracy and precision in machining. Imagine cutting cupcakes with a ruler instead of a messy knife—much better, right? It also gives operators enhanced control over lathe functions. Think of it like having a remote for your robot vacuum. You get to decide exactly where it goes! With these improvements, you can create better parts and reduce errors.

| Benefits | Description |

|---|---|

| Improved Accuracy | Machining with higher precision, reducing mistakes. |

| Enhanced Control | Better command over lathe functions for smooth operation. |

Preparing for Installation

Tools and materials required for lathe CNC encoder installation. Safety precautions to take before beginning the installation.Before diving into a lathe CNC encoder installation, gather your tools. Here’s a quick checklist:

| Tools | Materials |

|---|---|

| Wrench | Encoder |

| Screwdriver | Mounting brackets |

| Wire stripper | Wiring cables |

Don’t forget safety gear! Wear goggles and gloves—your fingers and eyes will thank you. Avoid loose clothing like a cape, just in case you turn into a superhero during installation!

Step-by-Step Installation Process

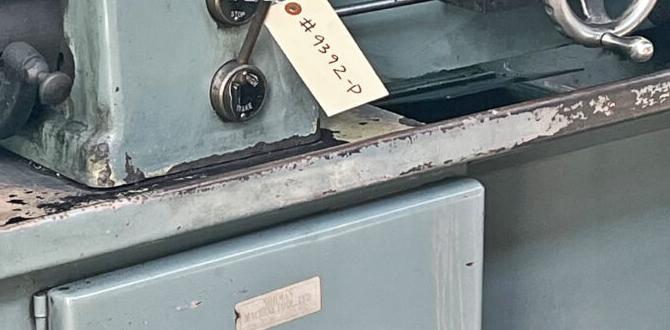

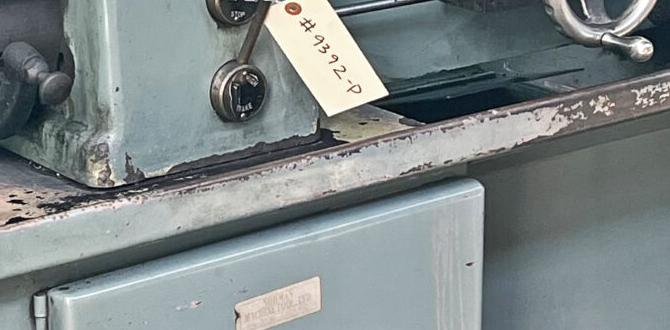

Removing existing components for encoder installation. Mounting the encoder securely on the lathe.Start by removing old parts from the lathe carefully. This prepares the machine for the new encoder. Next, find the right spot to attach the encoder. Ensure it fits snugly and stands firm. Use screws to hold it securely. Check that it aligns perfectly with the machine’s components. Taking these steps will help the encoder work smoothly. Remember, a stable setup means better performance!

Why It Is Important to Remove Existing Components?

Removing old components ensures a clean and safe installation for the new encoder. It prevents conflicting parts and allows for better functionality.

How Do You Mount the Encoder Properly?

- Choose an appropriate mounting location.

- Align the encoder with existing components.

- Tighten screws firmly to avoid movement.

- Double-check the fit before powering the machine.

Wiring and Connections

Detailed guide on wiring the CNC encoder to the lathe’s control unit. Common wiring mistakes to avoid during installation.Wiring your CNC encoder is crucial for a smooth setup. Start by connecting the encoder wires to the lathe’s control unit correctly. Follow the color codes to avoid confusion. Here are some common mistakes to steer clear of:

- Incorrect wire placement

- Forgetting to secure connections

- Not double-checking voltage levels

Always remember, a proper connection leads to better performance!

What should I consider during wiring?

Look for correct connections, double-check wire colors, and ensure secure fittings. Always read the manual for specifics. Your CNC encoder will work much smoother with these steps!

Configuring the CNC System

Adjusting settings in the CNC software for optimal performance. Calibration process to ensure accuracy postinstallation.To set up your CNC system, you need to adjust some key settings in the software. This ensures your machine works well. Calibration is also important. It helps check if everything is accurate after you install the encoder. Here are some quick steps for configuring:

- Open CNC software and find the settings menu.

- Input your machine’s specifications and size.

- Run a test to see if all parts move correctly.

- Adjust speeds and feeds based on material types.

- Double-check all measurements to ensure accuracy.

Following these steps will help your CNC work smoothly. Remember, a good setup can make a big difference in your project quality!

What is the importance of calibration after installation?

Calibration ensures that your CNC machine runs with precision. It keeps everything in line, reducing mistakes. Without proper calibration, you might face issues like inaccurate cuts or mismatched dimensions.

Troubleshooting Common Issues

Identifying and resolving wiring problems. Ensuring correct encoder signal output.Sometimes your CNC encoder might act like a mischievous cat, causing trouble. First, check those wires! A loose connection can lead to a big headache. Tighten everything and see if that fixes it. If not, you might have a signal issue. Make sure the encoder sends a clear output signal. If it’s fuzzy, it’s like your favorite TV show with bad reception.

| Issue | Solution |

|---|---|

| Loose wires | Tighten connections |

| Poor signal output | Check encoder settings |

| Incorrect wiring | Refer to the manual |

Remember, solving these problems can make your CNC run smoother. It’s like giving it a nice cup of coffee – it just gets more energetic and ready to work!

Maintenance Tips for Longevity

Regular checks to keep the encoder functioning optimally. Signs of wear and when to consider replacement.To keep your lathe CNC encoder running well, regular checks are key. Look for any signs of wear, such as strange noises or inconsistent readings. Catching problems early can save money. Here are some simple tips for maintenance:

- Check connections for dirt or dust.

- Calibrate regularly to ensure accuracy.

- Listen for unusual sounds during operation.

- Observe any changes in performance.

If you notice significant wear, it might be time for a replacement. Keeping an eye on these signs can help your encoder last longer, saving you from costly delays.

What should I check regularly on my encoder?

Regular checks include connections, calibration, and listening for sounds. These help ensure it runs smoothly and highlights any problems early.

Case Studies of Successful Installations

Realworld examples of enhanced performance postinstallation. Testimonials from users on improved lathe capabilities.Many users have shared successful stories about their lathe CNC encoder installations. For example, a local machine shop increased its productivity by 25% after upgrading their system. Another user reported smoother and more precise cuts, leading to fewer material waste and greater profits. Here are some key takeaways from these experiences:

- Improved speed and accuracy.

- Less downtime due to better reliability.

- Higher quality finished products.

These examples show that with the right upgrades, performance and satisfaction can really skyrocket!

How does a lathe CNC encoder improve performance?

A lathe CNC encoder enhances performance by providing precise feedback. This allows for better cutting accuracy and faster operations, leading to improved overall efficiency.

Conclusion

In conclusion, installing a CNC encoder on your lathe enhances accuracy and control. Start by gathering the right tools and reading the manual. Remember to secure all connections tightly. Don’t hesitate to ask for help if needed. For more detailed guidance, check online resources or videos. With practice, you’ll master this installation in no time!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cnc Encoder Installation:Sure! Installing a lathe CNC (Computer Numerical Control) encoder helps the machine know where it is. First, make sure you turn off the power. Next, you attach the encoder near the spindle of the lathe. You will connect the wires from the encoder to the control box. Finally, turn the power back on and test it to see if it works!

Sure! Please provide the question you would like me to answer.

What Are The Essential Components Required For Installing An Encoder On A Cnc Lathe?To install an encoder on a CNC lathe, you need a few important parts. First, you need the encoder itself, which helps measure the position. You also need a power supply to give energy to the encoder. Then, you will need wiring to connect everything together. Finally, you may need some tools, like a screwdriver, to help with the installation.

How Do You Determine The Correct Encoder Type And Resolution Needed For A Specific Cnc Lathe Application?To choose the right encoder for your CNC lathe, you start by thinking about what you need it to do. First, consider the movements and positions you want to measure. Then, look at the encoder’s type, like whether it counts steps or turns. Finally, check the resolution, which is how much detail it can detect. Higher resolution means more precision!

What Are The Common Installation Steps For Mounting An Encoder On A Cnc Lathe, And What Tools Are Necessary For The Process?To mount an encoder on a CNC lathe, you first need to turn off the machine. Then, you clean the area where you will install the encoder. Next, you place the encoder on its spot and secure it with screws. After that, connect the wires to the machine. You will need tools like a screwdriver, a wrench, and some safety glasses.

How Can You Troubleshoot Issues Related To Encoder Signals After Installation On A Lathe Cnc?To troubleshoot encoder signals after installing it on a lathe CNC, you can start by checking the connections. Make sure all wires are securely plugged in. Then, look for any visible damage on the cables. You can also test the encoder with a multimeter to see if it’s working correctly. If things still aren’t right, consult the machine’s manual for more help.

What Safety Precautions Should Be Taken During The Installation Of An Encoder On A Cnc Lathe?When we install an encoder on a CNC lathe, we need to be very careful. First, turn off the machine completely to avoid accidents. Then, wear safety glasses to protect your eyes. It’s also good to keep your hands and clothing away from moving parts. Finally, ask an adult for help if you’re not sure what to do.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cnc Encoder Installation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Installing a lathe CNC (Computer Numerical Control) encoder helps the machine know where it is. First, make sure you turn off the power. Next, you attach the encoder near the spindle of the lathe. You will connect the wires from the encoder to the control box. Finally, turn the power back on and test it to see if it works!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Required For Installing An Encoder On A Cnc Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install an encoder on a CNC lathe, you need a few important parts. First, you need the encoder itself, which helps measure the position. You also need a power supply to give energy to the encoder. Then, you will need wiring to connect everything together. Finally, you may need some tools, like a screwdriver, to help with the installation.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Encoder Type And Resolution Needed For A Specific Cnc Lathe Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right encoder for your CNC lathe, you start by thinking about what you need it to do. First, consider the movements and positions you want to measure. Then, look at the encoder’s type, like whether it counts steps or turns. Finally, check the resolution, which is how much detail it can detect. Higher resolution means more precision!”}},{“@type”: “Question”,”name”: “What Are The Common Installation Steps For Mounting An Encoder On A Cnc Lathe, And What Tools Are Necessary For The Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To mount an encoder on a CNC lathe, you first need to turn off the machine. Then, you clean the area where you will install the encoder. Next, you place the encoder on its spot and secure it with screws. After that, connect the wires to the machine. You will need tools like a screwdriver, a wrench, and some safety glasses.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Issues Related To Encoder Signals After Installation On A Lathe Cnc?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot encoder signals after installing it on a lathe CNC, you can start by checking the connections. Make sure all wires are securely plugged in. Then, look for any visible damage on the cables. You can also test the encoder with a multimeter to see if it’s working correctly. If things still aren’t right, consult the machine’s manual for more help.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During The Installation Of An Encoder On A Cnc Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we install an encoder on a CNC lathe, we need to be very careful. First, turn off the machine completely to avoid accidents. Then, wear safety glasses to protect your eyes. It’s also good to keep your hands and clothing away from moving parts. Finally, ask an adult for help if you’re not sure what to do.”}}]}