Have you ever wondered how metal workers create such precise parts? One tool that helps them is the lathe collet system. This system holds workpieces tightly in place. It’s like a strong hand gripping a pencil, allowing for detailed work.

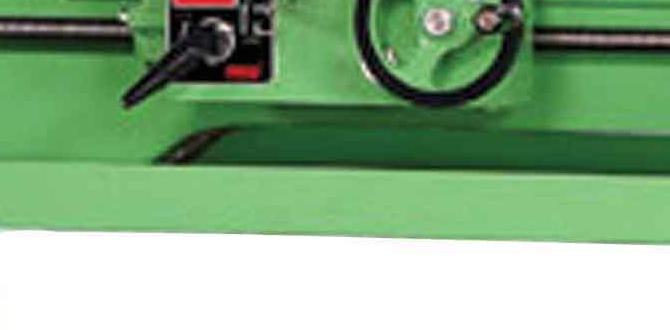

When looking for a metal lathe, you might feel overwhelmed by all the brands out there. Each brand offers different features. Some are well-known for their quality. Others may surprise you with their affordability. How do you choose?

Imagine you need to create a custom part for a school project. A reliable lathe collet system can make a big difference. It simplifies the setup and helps you get the job done smoothly. In this article, we will explore various metal lathe brands and their collet systems. You’ll learn what makes each one unique.

Let’s dive deeper into the fascinating world of metal lathes. You might discover a brand that fits your needs perfectly!

Lathe Collet System: Top Metal Lathe Brands Explained

Lathe Collet System and Metal Lathe Brands

A lathe collet system holds workpieces tightly. Did you know that different metal lathe brands offer various collet styles? This variety can really enhance your projects! Not all lathes are the same; some brands provide better precision and ease of use. Popular names like Grizzly and Jet are known for their reliability. When choosing a metal lathe, consider the compatibility of collets. A good collet system can make your metalworking experience smoother and more efficient.What is a Lathe Collet System?

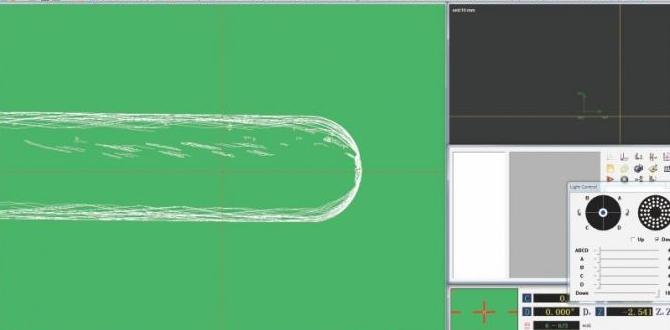

Definition and purpose of collet systems in metal lathes. Types of collets and their applications.A lathe collet system helps hold and grip tools in a metal lathe. This system ensures precision during cutting and shaping. Collets are versatile and come in various types, each serving a unique purpose. They enable quick changes between tools, saving time in projects. Here are two main types:

- Standard Collets: Used for general purposes, they hold different tool sizes securely.

- Specialty Collets: Designed for specific tasks, such as holding odd shapes or materials.

Collet systems improve work efficiency and accuracy, making them essential for any metal lathe user.

What are the main benefits of using a lathe collet system?

The main benefits include increased precision, faster tool changes, and improved grip on workpieces. These advantages make collet systems popular among machinists.

Benefits of Using a Collet System in Metal Lathes

Enhanced precision and repeatability in machining. Quick tool changes and improved productivity.A collet system offers many great benefits for metal lathes. It helps improve precision in machining tasks. This means parts fit better and work well together. It also offers repeatability. You can make the same part over and over with great accuracy.

Switching tools is quick and easy with this system. This saves valuable time. More time means better productivity! Overall, using a collet system makes machining more efficient and helps produce high-quality parts.

Why should I use a collet system in metal lathes?

Using a collet system increases precision and allows for faster tool changes. This means you get better results and save time.

Key benefits include:

- Enhanced precision

- Higher repeatability

- Quick tool changes

- Improved productivity

Key Features to Consider When Choosing a Collet System

Compatibility with different lathe models. Material and construction quality for durability.Choosing the right collet system can be a bit tricky, like picking the best pizza topping! First, check compatibility with your lathe model, because the wrong fit can turn your project into a disaster. Next, focus on material and construction quality. A solid build means it will last longer, which is great—trust us, you don’t want it breaking during a crucial moment!

| Feature | Importance |

|---|---|

| Compatibility | Ensures smooth operation |

| Material Quality | Enhances durability |

Popular Types of Collets for Metal Lathes

Description of standard, hexagonal, and specialty collets. Advantages and uses of each type in metalworking.Collets are special tools for holding workpieces securely while using a metal lathe. There are three popular types of collets: standard, hexagonal, and specialty collets. Each has unique uses and advantages.

- Standard Collets: These are the most common. They offer good grip on various shapes. They are great for basic turning tasks.

- Hexagonal Collets: These hold hex-shaped pieces tightly. They are perfect for projects needing precise angles.

- Specialty Collets: Designed for unique shapes and sizes, they help handle unique projects smoothly.

Using the right collet improves your work’s quality and safety. Choose the one that fits your metalworking needs best!

What are the advantages of using different collet types?

Each collet type provides better grip, efficiency, and precision. Using them correctly makes metalworking simpler and more effective!

Maintenance and Care for Lathe Collet Systems

Best practices for cleaning and storing collets. Tips for ensuring longevity and performance.To keep your lathe collet system in tip-top shape, cleanliness is key. Always wipe down your collets after use to remove grime. A soft cloth and some mild cleaner will work wonders. Store them in a dry, safe space—nobody likes a rusty collet! For longevity, check for wear and tear; a small crack can lead to big problems. Remember, even collets need their spa day!

| Best Practices | Tips for Longevity |

|---|---|

| Clean after each use | Inspect regularly for damage |

| Store in a dry area | Avoid dropping or mishandling |

| Use soft cleaning cloths | Lubricate occasionally |

Following these simple steps can help keep your collet system performing like a pro! Remember, happy collets = happy lathe!

Frequently Asked Questions about Lathe Collet Systems

Common misconceptions and queries addressed. Expert recommendations for new users.Many people think collet systems are super complicated, but they are easier than a pizza slice! A common question is, “Do I need to buy a special lathe?” The answer is no! Most lathes can work fine with collet systems. For beginners, experts suggest starting with brands like Taig or Grizzly. They’re as reliable as your favorite superhero! Remember, always check if the collet fits your lathe before buying. Here’s a quick FAQ table:

| Question | Answer |

|---|---|

| Can I use a collet with any lathe? | No, make sure it fits your machine! |

| Which brands are best for beginners? | Taig and Grizzly are great starters! |

| Are collets really worth it? | Absolutely! They help make precise cuts. |

Conclusion

In summary, lathe collet systems help you grip materials securely on metal lathes. Different brands offer unique features, so choose wisely. Research and compare options to find the best fit for your needs. Don’t forget to explore reviews and guides to deepen your understanding. With the right lathe and collet system, you can create amazing projects!FAQs

What Are The Advantages Of Using A Collet System Over Standard Chucks In Metal Lathes?A collet system holds the workpiece tightly and evenly. This means less chance of slipping while you work. Collets are easier to change than standard chucks. They also make it quicker to switch between different sizes, saving you time. Overall, using a collet system gives you better control and helps you do a cleaner job.

Which Brands Are Known For Manufacturing High-Quality Collet Systems For Metal Lathes?Some well-known brands that make high-quality collet systems for metal lathes are Hardinge, machinists like Royal, and Erickson. These brands create tools that help hold metal pieces tightly while we work on them. You can trust these brands because they are used by many workers and hobbyists. They make sure your metal projects turn out great!

How Do I Determine The Appropriate Collet Size For My Specific Metal Lathe Brand?To find the right collet size for your metal lathe, first check your lathe’s manual. This manual usually lists compatible collet sizes. You can also measure the spindle, where the collet fits. Finally, ask a store expert for help. They can guide you to the right size for your specific lathe.

Are There Any Compatibility Issues Between Collet Systems And Different Metal Lathe Brands?Yes, there can be compatibility issues between collet systems and different metal lathe brands. Each brand might have unique sizes and shapes for their collets. If you have a collet from one brand, it might not fit another brand’s lathe. It’s important to check if they match before using them together. Always ask a teacher or a helper if you’re not sure!

What Are Some Best Practices For Maintaining Collet Systems To Ensure Precision And Longevity In Metal Lathes?To keep collet systems working well on metal lathes, you should clean them regularly. Dust and dirt can mess up their accuracy. Always check for wear and tear so you can catch problems early. Use proper tools to install and remove the collets to avoid damage. Lastly, store them in a safe place to prevent accidents and keep them in good shape.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over Standard Chucks In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system holds the workpiece tightly and evenly. This means less chance of slipping while you work. Collets are easier to change than standard chucks. They also make it quicker to switch between different sizes, saving you time. Overall, using a collet system gives you better control and helps you do a cleaner job.”}},{“@type”: “Question”,”name”: “Which Brands Are Known For Manufacturing High-Quality Collet Systems For Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some well-known brands that make high-quality collet systems for metal lathes are Hardinge, machinists like Royal, and Erickson. These brands create tools that help hold metal pieces tightly while we work on them. You can trust these brands because they are used by many workers and hobbyists. They make sure your metal projects turn out great!”}},{“@type”: “Question”,”name”: “How Do I Determine The Appropriate Collet Size For My Specific Metal Lathe Brand? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right collet size for your metal lathe, first check your lathe’s manual. This manual usually lists compatible collet sizes. You can also measure the spindle, where the collet fits. Finally, ask a store expert for help. They can guide you to the right size for your specific lathe.”}},{“@type”: “Question”,”name”: “Are There Any Compatibility Issues Between Collet Systems And Different Metal Lathe Brands? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there can be compatibility issues between collet systems and different metal lathe brands. Each brand might have unique sizes and shapes for their collets. If you have a collet from one brand, it might not fit another brand’s lathe. It’s important to check if they match before using them together. Always ask a teacher or a helper if you’re not sure!”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Maintaining Collet Systems To Ensure Precision And Longevity In Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep collet systems working well on metal lathes, you should clean them regularly. Dust and dirt can mess up their accuracy. Always check for wear and tear so you can catch problems early. Use proper tools to install and remove the collets to avoid damage. Lastly, store them in a safe place to prevent accidents and keep them in good shape.”}}]}