Have you ever wondered how metal parts are made with such precision? At the heart of this craft is the lathe. It’s a machine that shapes metal into useful items.

One key part of a lathe is the collet system. This system helps hold and secure the metal piece tightly. Imagine trying to hold a small nail while hammering. It would be tricky, right? The collet system makes the job much easier.

Whether you are a beginner or an expert, understanding the lathe collet system is important. It helps improve your work with the metal lathe carriage. You can create cleaner cuts and better shapes.

Did you know that using a proper collet can make a huge difference? Many beginners overlook this, but it can change how well your project turns out. Let’s explore the details behind these tools and see how they can help you become a better machinist.

Understanding The Lathe Collet System In Metal Lathe Carriage

Understanding the Lathe Collet System in Metal Lathe Carriage

The lathe collet system holds tools and materials securely. It offers better precision than a standard chuck. This system is great for small workpieces, often used in metalworking. Did you know? A collet can grip a range of sizes, making it super versatile. In a metal lathe carriage, it allows smooth movement and accurate cuts. Knowing how this system works can boost your skills and improve your projects! Have you tried using a collet yet?Understanding Lathe Collet Systems

Definition and function of collet systems in metal lathes. Types of collet systems: standard vs. precision collets.A lathe collet system is like a fancy handshake for your workpiece. It holds your material securely while the lathe spins it round and round. You have two main types: standard collets and precision collets. Standard collets are reliable for general projects, while precision collets provide a tighter grip for detailed work. Think of precision collets as the overachievers of the bunch! They ensure that even the tiniest parts stay put while you work your magic.

| Type of Collet | Best For |

|---|---|

| Standard Collets | General use and simple projects |

| Precision Collets | High-accuracy tasks and delicate materials |

Benefits of Using a Collet System in Metal Lathes

Enhanced workpiece stability and accuracy. Increased versatility for different workpieces and machining tasks.Using a collet system in a metal lathe brings some cool perks. First, it gives you better workpiece stability. Your materials won’t wiggle around as much, making everything super accurate, like a dart at a bullseye! Next, it boosts flexibility. You can easily switch between different tasks and pieces. Need to shape a tiny screw or a big chunk of metal? No problem! The collet system is like a magic box that handles it all.

| Benefit | Description |

|---|---|

| Stability | Reduces movement for better accuracy. |

| Versatility | Easily switch between different workpieces and tasks. |

Types of Collets for Metal Lathes

Description of common collet types: ER, 5C, and others. Comparison of collet types based on application and compatibility.Collets are essential for holding tools in metal lathes. There are various types, each with unique features. Here are some common types:

- ER Collets: These are versatile and widely used. They can hold many shapes and sizes.

- 5C Collets: These are popular for their precision. They are perfect for holding round workpieces.

- Other Collet Types: There are also 3J and 16C. These serve more specialized needs.

Choosing the right collet depends on your project. ER collets fit many tools, while 5C collets excel with round items. Compatibility is key. Using the wrong collet can affect accuracy. So, always pick the right tool for the job!

What are the main differences between ER and 5C collets?

The main difference is in flexibility and applications. ER collets are more versatile, suitable for various shapes. In contrast, 5C collets are known for holding round pieces tightly and accurately.

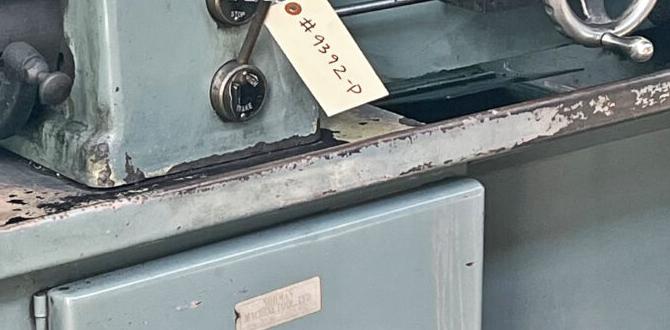

Installation and Setup of the Collet System

Stepbystep guide to installing a collet system on a metal lathe. Tips for aligning and securing collets for precision work.Setting up a collet system on your metal lathe can feel like launching a rocket, but it’s much easier! Start by cleaning your lathe to remove any dust bunnies hiding in corners. Next, securely attach the collet chuck. Check that it fits snugly—like your favorite pair of sneakers! For precise work, it’s essential to align your collets. Use a dial indicator to ensure perfect placement. A few twists of the wrench, and voilà! You’re ready to work. Remember, collets love a good snug hug—just not too tight!

| Step | Action |

|---|---|

| 1 | Clean the lathe |

| 2 | Attach the collet chuck |

| 3 | Align using a dial indicator |

| 4 | Secure collets tightly |

Maintenance and Care for Lathe Collet Systems

Routine maintenance practices to ensure longevity and performance. Troubleshooting common issues with collet systems.Taking care of your lathe collet system is like brushing your teeth; it keeps things running smoothly! Regular cleaning helps remove dust and chips. Don’t forget to check for wear and tear; after all, you wouldn’t wear a holey sock, would you? If something seems off, like a collet not gripping tight, try tightening it first. If that doesn’t fix it, consult the manual—it’s a lifesaver!

| Routine Maintenance | Troubleshooting Tips |

|---|---|

| Clean after use | Check for loose parts |

| Inspect for damage | Ensure collet is properly seated |

| Oil moving parts | Replace worn collets |

Applications of Collet Systems in Metalworking

Industrial applications: machining, fabrication, and assembly. Hobbyist applications: modelmaking and custom projects.Collet systems are very useful in metalworking. They help hold pieces tightly so tools can cut or shape them. For industrial work, they are great for:

- Machining: Making precise parts quickly.

- Fabrication: Building items from raw materials.

- Assembly: Putting together parts efficiently.

Hobbyists also love collet systems. They use them for:

- Modelmaking: Creating detailed models and miniatures.

- Custom projects: Making unique items just for fun.

Many people enjoy using collet systems. They make tasks easier and more fun!

What are the main benefits of using collet systems in metalworking?

The main benefits include better precision, faster work, and easy tool changes.

Comparing Collet Systems vs. Traditional Chuck Systems

Advantages and disadvantages of collet systems over chuck systems. Situations where collet systems provide superior results.Collet systems and chuck systems each have their own quirks. Collet systems wrap around the workpiece tightly, offering greater precision. This is a win for small parts! However, they may struggle with larger pieces. On the flip side, traditional chucks are like the reliable old friend. They can hold big things quite well but may miss the finer details. In situations requiring high accuracy, collet systems truly shine as the way to go!

| Feature | Collet Systems | Chuck Systems |

|---|---|---|

| Precision | High | Medium |

| Size range | Small to Medium | Large |

| Setup time | Quick | Slower |

Choosing the Right Collet System for Your Metal Lathe

Factors to consider: lathe size, workpiece types, and precision requirements. Recommended brands and models for various applications.Selecting the right collet system is important for your metal lathe. Start with the lathe size; this ensures the collet fits perfectly. Next, think about the workpiece types. Different materials need different collets. Finally, consider precision requirements. Do you need high accuracy or is a little wiggle okay? Popular brands include:

- Jacobs

- ER Collets

- Albrecht

- Weldon

These brands offer models suited for various tasks. Remember, the right collet can make your work easier and more precise.

What should I consider when choosing a collet system?

Consider the size of your lathe, the types of materials you work with, and how much precision you need.

Conclusion

In conclusion, a lathe collet system is essential for holding workpieces securely on a metal lathe carriage. It allows for precision and efficiency in shaping metal. We encourage you to explore more about different collet types and how they can improve your projects. By learning more, you can enhance your metalworking skills and create better results.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Carriages:1. What is a lathe collet system? A lathe collet system holds the metal tight when you work on it. It helps keep things safe and steady. 2. How does a metal lathe carriage work? The metal lathe carriage moves the cutting tool back and forth. It helps shape the metal by making it spin. 3. Why are collets better than regular chucks? Collets hold metal better than chucks. They grip tighter and let you work more accurately. 4. Can you use different sizes of collets? Yes, you can use different sizes of collets. Each one fits a specific size of metal, so you can choose the right one. 5. How do you change the collet? To change the collet, you loosen it and pull it out. Then, put in the new one and tighten it up.

Sure! Please provide a question for me to answer.

What Is The Primary Function Of A Collet System In A Metal Lathe, And How Does It Differ From Traditional Chuck Systems?A collet system helps hold a metal piece tightly in a lathe. It can hold smaller, more precise shapes better than a traditional chuck. A traditional chuck grips the piece from the outside, while collets snugly fit around it. This makes collets great for detailed work. You can switch collets quickly to fit different sizes of metal pieces.

How Do You Properly Set Up And Align A Collet System On A Metal Lathe To Ensure Optimal Precision During Machining?To set up a collet system on a metal lathe, first, make sure the lathe is off. Next, choose the right collet for your workpiece. Then, place the collet in the lathe’s spindle; it should fit tightly. After that, tighten the collet by spinning the handle clockwise. Finally, check if the workpiece is straight and secure before starting the machine.

What Are The Advantages Of Using A Collet System Over A Standard Three-Jaw Or Four-Jaw Chuck For Turning Operations?Using a collet system is great because it holds the piece more tightly and evenly. This means you get better shapes and surfaces when you work. Collets can hold different sizes without changing parts, making it faster and easier. They also take up less space and can handle smaller pieces better. Overall, collets help you do a cleaner job!

In What Situations Would You Choose A Specific Type Of Collet (E.G., Er Collet, Collet) For A Metal Lathe, And What Are The Characteristics Of Each?If you need to hold small tools, you might use an ER collet. ER collets are good because they can hold different sizes tightly. If you’re working with larger tools or parts, a standard collet might be better. Standard collets are strong and hold round shapes well. Always choose the type that fits your tool’s size and shape best!

How Can Maintenance Of The Collet System And Lathe Carriage Impact The Overall Performance And Longevity Of The Lathe?Taking care of the collet system and lathe carriage is important for your lathe. When we keep these parts clean and oiled, they work better. This means our projects turn out smoother and faster. Good maintenance helps the lathe last longer, saving us money. So, by checking and fixing these parts, we can enjoy using our lathe for years!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Carriages:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “1. What is a lathe collet system? A lathe collet system holds the metal tight when you work on it. It helps keep things safe and steady. 2. How does a metal lathe carriage work? The metal lathe carriage moves the cutting tool back and forth. It helps shape the metal by making it spin. 3. Why are collets better than regular chucks? Collets hold metal better than chucks. They grip tighter and let you work more accurately. 4. Can you use different sizes of collets? Yes, you can use different sizes of collets. Each one fits a specific size of metal, so you can choose the right one. 5. How do you change the collet? To change the collet, you loosen it and pull it out. Then, put in the new one and tighten it up.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide a question for me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Collet System In A Metal Lathe, And How Does It Differ From Traditional Chuck Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system helps hold a metal piece tightly in a lathe. It can hold smaller, more precise shapes better than a traditional chuck. A traditional chuck grips the piece from the outside, while collets snugly fit around it. This makes collets great for detailed work. You can switch collets quickly to fit different sizes of metal pieces.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Collet System On A Metal Lathe To Ensure Optimal Precision During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a collet system on a metal lathe, first, make sure the lathe is off. Next, choose the right collet for your workpiece. Then, place the collet in the lathe’s spindle; it should fit tightly. After that, tighten the collet by spinning the handle clockwise. Finally, check if the workpiece is straight and secure before starting the machine.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over A Standard Three-Jaw Or Four-Jaw Chuck For Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system is great because it holds the piece more tightly and evenly. This means you get better shapes and surfaces when you work. Collets can hold different sizes without changing parts, making it faster and easier. They also take up less space and can handle smaller pieces better. Overall, collets help you do a cleaner job!”}},{“@type”: “Question”,”name”: “In What Situations Would You Choose A Specific Type Of Collet (E.G., Er Collet, Collet) For A Metal Lathe, And What Are The Characteristics Of Each?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you need to hold small tools, you might use an ER collet. ER collets are good because they can hold different sizes tightly. If you’re working with larger tools or parts, a standard collet might be better. Standard collets are strong and hold round shapes well. Always choose the type that fits your tool’s size and shape best!”}},{“@type”: “Question”,”name”: “How Can Maintenance Of The Collet System And Lathe Carriage Impact The Overall Performance And Longevity Of The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Taking care of the collet system and lathe carriage is important for your lathe. When we keep these parts clean and oiled, they work better. This means our projects turn out smoother and faster. Good maintenance helps the lathe last longer, saving us money. So, by checking and fixing these parts, we can enjoy using our lathe for years!”}}]}