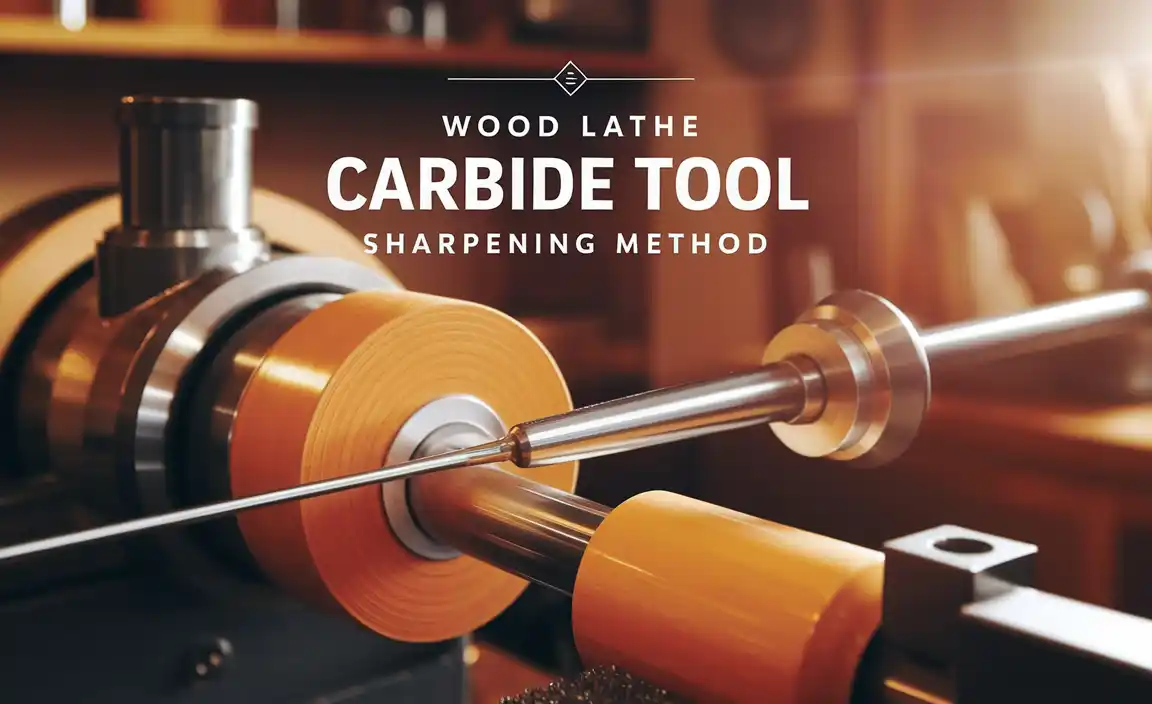

Have you ever wondered how metal parts are shaped with precision? The key often lies in a lathe collet system. This handy tool makes it easy to hold and rotate metal pieces while crafting them into desired shapes.

If you’re new to metalworking, you might be curious about how to use such a system. Imagine working on a project where every detail matters. A lathe collet system can give you that edge. It allows for quick changes and adjustments, so you can focus on your design.

But that’s not all! Adding a digital readout (DRO) can enhance your experience even more. This smart tool helps you see exact measurements at a glance. With a lathe collet system and a DRO, you can make stunning projects with ease.

Did you know that even small mistakes in measurements can lead to big problems in metalworking? Having the right tools is essential. So, whether you’re a hobbyist or a seasoned pro, understanding lathe collet systems can make all the difference.

Let’s explore the exciting world of metal lathes and how these systems can help you create amazing things!

Lathe Collet System For Metal Lathe Dro: Efficiency Unleashed

Lathe Collet System and Metal Lathe DRO

The lathe collet system is essential for securely holding workpieces while machining. It offers precision and quick tool changes, making it popular among hobbyists and professionals. A metal lathe DRO, or digital readout, enhances accuracy by displaying real-time measurements. Imagine crafting a complex part without the fear of measurements being off! By combining these tools, you can achieve better results and streamline your projects. Are you ready to take your metalworking to the next level?What is a Lathe Collet System?

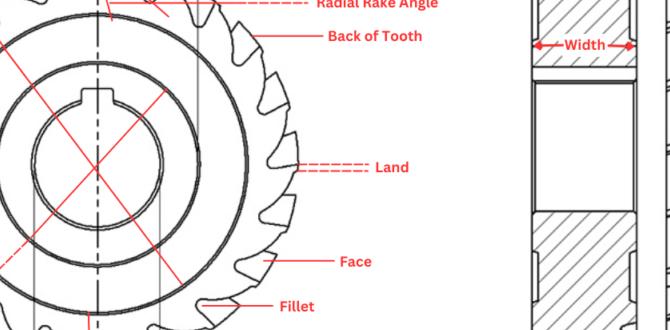

Definition and purpose of collet systems in metal lathes. Differences between collets and traditional chucks.A lathe collet system is a tool that grips workpieces tightly for shaping and cutting. Think of it as a friendly hug for your metal! Unlike traditional chucks, which can be a bit picky, collets hold items uniformly around their sides. This means better precision. Collets come in various sizes, perfect for different jobs. Here’s a quick comparison:

| Feature | Collets | Chucks |

|---|---|---|

| Grip | Tight and balanced | Wider, not as tight |

| Usage | Great for precision work | Good for larger pieces |

| Setup | Quick to change | More fiddly |

In the battle of grips, collets definitely bring their A-game! Who knew metalworking could be this fun?

Advantages of Using a Collet System

Enhanced precision and repeatability in machining. Versatility in holding various workpieces.Using a collet system is like having a superhero in your workshop. First, it offers enhanced precision and repeatability. This means your cuts will be just as perfect the hundredth time as they were the first! No more wobbly parts running around like they have ants in their pants.

Second, it’s versatile. Collets can hold different shapes and sizes of workpieces, from tiny bolts to big chunks of metal. Instead of juggling tools and wasting time, a collet system does the heavy lifting for you. It’s your ultimate sidekick in machining!

| Advantages | Description |

|---|---|

| Precision | Consistent and accurate cuts every time. |

| Versatility | Holds various shapes and sizes without hassle. |

How to Choose the Right Collet for Your Metal Lathe

Factors to consider: size, type, and material. Matching collets to specific machining operations.Choosing the right collet for your metal lathe is like picking out the perfect ice cream flavor. You need to consider a few important factors. First, think about size. A too big or too small collet is like trying to fit into socks two sizes too big—squishy and uncomfortable! Next, the type matters. Different collets work best for different jobs, like how some tools are great for building and others are better for fixing. Finally, the material can affect performance. Collets made from tougher materials hold up better. Remember, matching the collet to your specific task will help you work better and smarter.

| Factor | Description |

|---|---|

| Size | Ensure the collet fits your workpiece properly. Size matters! |

| Type | Choose a type that matches your machining operation. |

| Material | Opt for durable materials for better performance. |

Integrating a Digital Readout (DRO) System

Benefits of using DRO with a lathe collet system. Features to look for in a DRO compatible with metal lathes.Using a digital readout (DRO) with a lathe collet system is like adding a superpower to your metal lathe! These systems keep track of measurements accurately, so you can say goodbye to guessing and hello to perfection. Cuts are more precise, and you can save time too. Look for DROs that are easy to install and have a clear display. Features like multi-axis support and a sturdy mounting system are essential. A good DRO brings your lathe to life, making your projects smoother than a buttered slide!

| Feature | Benefit |

|---|---|

| Clear Display | Easy to read measurements |

| Multi-Axis Support | Work on complex designs |

| Sturdy Mounting | Lasting durability |

Step-by-Step Guide: Setting Up a Lathe Collet System

Preparation and safety measures before setup. Detailed instructions for installation and alignment.Before setting up your lathe collet system, safety is key. Always wear protective gear like gloves and goggles. Make sure your workspace is clean. Preparation helps prevent accidents.

Next, follow these steps to install and align:

- Check the collet size and compatibility.

- Loosen the drawbar and insert the collet.

- Tighten the drawbar securely.

- Align the tailstock with the spindle.

- Test the setup with a small workpiece.

With careful preparation and alignment, your system will work great!

What should I do before starting the lathe?

Always check your tools and ensure your area is free from hazards. Safety should always come first in any workshop activity.

Common Issues and Troubleshooting

Identifying and solving common problems with collet gripping. Tips for maintaining the collet system to ensure longevity.Collet gripping can sometimes be tricky. Problems like gripping too loosely or unevenly often occur. To fix these issues, check for dirt or damage. Clean your collets regularly. Here are some useful tips:

- Always inspect the collets for wear.

- Keep them clean and free from chips.

- Tighten connections securely but not too tight.

Maintaining your collet system helps it last longer. A little care goes a long way!

What are common problems with collet gripping?

Common problems include loose gripping, uneven pressure, and dirt buildup.

Real-World Applications of Lathe Collet Systems

Examples of industries using collet systems effectively. Success stories showcasing precision improvements with DRO integration.Many industries benefit from lathe collet systems. They ensure parts are made with high precision. Fields like aerospace, automotive, and manufacturing use these tools. For example, an aerospace company improved its part accuracy by 30% after using a DRO with collet systems. They were able to make components faster and with fewer mistakes. This not only saved time but also money. Precision matters, and companies strive for the best results every day.

What industries use collet systems?

Many industries like aerospace, automotive, and metalworking rely on collet systems for their precision and efficiency.

Real-world examples include:

- Aerospace: Improved part accuracy by 30%.

- Automotive: Increased productivity with fewer defects.

- Manufacturing: Enhanced production speed and quality.

Cost Considerations: Investing in a Quality Collet System

Breakdown of costs associated with different collet systems. Longterm savings from improved machining accuracy and efficiency.Buying a collet system can feel like a wallet workout, but it’s worth it! Different systems come at different prices, so plan well. Here’s a quick breakdown:

| Collet System | Cost | Benefits |

|---|---|---|

| Standard System | $100 – $300 | Good for light use |

| High-Precision System | $400 – $800 | Best machining accuracy |

Investing in a quality collet system means less time fixing mistakes and more time making cool stuff. More accuracy means long-term savings, as you won’t waste materials or time on do-overs. Remember, a happy lathe is a productive lathe!

Conclusion

In summary, a lathe collet system is essential for metal lathes. It securely holds tools for precise cuts. A DRO, or digital readout, helps you measure accurately as you work. Together, they improve your skills and project quality. If you want to learn more, explore tutorials or guides on using these tools. Start practicing, and watch your projects shine!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Digital Readouts (Dro) For Metal Lathes:Lathe collet systems help hold metal pieces tightly while you work. They make it easier to change parts quickly. Digital Readouts (DRO) show you precise measurements on a screen. This helps you make accurate cuts and shapes. Using both tools makes metalworking more fun and precise!

Of course! Please give me the question you’d like me to answer.

What Are The Advantages Of Using A Collet System Over A Chuck System On A Metal Lathe?A collet system holds the metal tightly and evenly. This means it can make smoother cuts. You can also change pieces quickly with a collet. It takes less time than using a chuck system, which can be slower. Overall, collets help you work faster and better!

How Do You Select The Appropriate Collet Size For Specific Machining Applications On A Lathe?To pick the right collet size for a lathe, first, measure the size of the tool or part you want to hold. Next, check the collet chart for matching sizes. We need a collet that fits snugly around the tool without being too loose. Make sure the collet is compatible with your lathe model. This way, you can clamp it securely for safe and steady machining!

What Features Should You Look For In A Digital Readout (Dro) System To Enhance Precision And Usability On A Metal Lathe?When you choose a digital readout (DRO) system for a metal lathe, look for a clear screen. This helps you see the numbers easily. You should also want buttons that are simple to use. A DRO that remembers your measurements can save you time. Finally, check that it is sturdy and works well in noisy places.

How Can A Dro Improve The Accuracy And Efficiency Of Machining Tasks When Using A Lathe Collet System?A DRO, or Digital Readout, helps us measure things very accurately on a lathe. It shows us exact numbers on a screen as we work. This means we can make better cuts without mistakes. When we use a DRO, we can finish our tasks faster because we don’t have to guess measurements. It makes working with a collet system much easier and more precise!

What Common Maintenance Practices Should Be Performed To Ensure The Longevity And Accuracy Of Both Collet Systems And Dro Units On Metal Lathes?To keep collet systems and Digital Readout (DRO) units working well, you should clean them regularly. Use a soft cloth to wipe away dust and grime. Check for any signs of wear or damage on parts. Make sure everything is properly lubricated to prevent rust. Finally, keep them dry to avoid moisture problems.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Digital Readouts (Dro) For Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe collet systems help hold metal pieces tightly while you work. They make it easier to change parts quickly. Digital Readouts (DRO) show you precise measurements on a screen. This helps you make accurate cuts and shapes. Using both tools makes metalworking more fun and precise!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over A Chuck System On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system holds the metal tightly and evenly. This means it can make smoother cuts. You can also change pieces quickly with a collet. It takes less time than using a chuck system, which can be slower. Overall, collets help you work faster and better!”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Collet Size For Specific Machining Applications On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick the right collet size for a lathe, first, measure the size of the tool or part you want to hold. Next, check the collet chart for matching sizes. We need a collet that fits snugly around the tool without being too loose. Make sure the collet is compatible with your lathe model. This way, you can clamp it securely for safe and steady machining!”}},{“@type”: “Question”,”name”: “What Features Should You Look For In A Digital Readout (Dro) System To Enhance Precision And Usability On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose a digital readout (DRO) system for a metal lathe, look for a clear screen. This helps you see the numbers easily. You should also want buttons that are simple to use. A DRO that remembers your measurements can save you time. Finally, check that it is sturdy and works well in noisy places.”}},{“@type”: “Question”,”name”: “How Can A Dro Improve The Accuracy And Efficiency Of Machining Tasks When Using A Lathe Collet System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A DRO, or Digital Readout, helps us measure things very accurately on a lathe. It shows us exact numbers on a screen as we work. This means we can make better cuts without mistakes. When we use a DRO, we can finish our tasks faster because we don’t have to guess measurements. It makes working with a collet system much easier and more precise!”}},{“@type”: “Question”,”name”: “What Common Maintenance Practices Should Be Performed To Ensure The Longevity And Accuracy Of Both Collet Systems And Dro Units On Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep collet systems and Digital Readout (DRO) units working well, you should clean them regularly. Use a soft cloth to wipe away dust and grime. Check for any signs of wear or damage on parts. Make sure everything is properly lubricated to prevent rust. Finally, keep them dry to avoid moisture problems.”}}]}