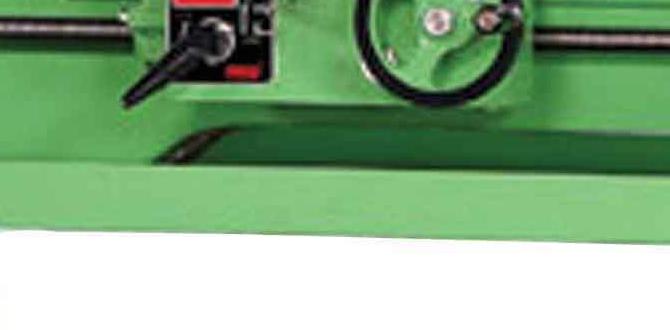

Have you ever wondered how metal parts are shaped with precision? Imagine a machine that can hold metal pieces tightly and allow for accurate cutting. This is where the lathe collet system comes into play. It’s a vital part of many metal lathes.

Using a collet system helps keep the material secure while it spins. This way, you can create gears and other important objects with ease. But what makes collets so special compared to other holding methods?

Here’s a fun fact: collets can grip multiple sizes of tools. This flexibility makes them popular among engineers and hobbyists alike. Picture yourself in a workshop, watching a skilled operator use a metal lathe to make an intricate gear. The collet system plays a key role in that magic!

In this article, we’ll explore how the lathe collet system works and why it matters for metal lathes. Get ready to dive into the fascinating world of precision metalworking!

Understanding The Lathe Collet System For Metal Lathe Gear

Understanding the Lathe Collet System

The lathe collet system is an essential tool for metal lathe users. It holds workpieces firmly in place, allowing for precise machining. Did you know that a sturdy collet can improve your cutting speed and accuracy significantly? This system simplifies changing tools and enhances efficiency. By using the right size collet, you can reduce vibrations and ensure better finishes. Explore how mastering the lathe collet system can transform your metalworking projects into success stories!What is a Lathe Collet System?

Definition and purpose of a collet system in metalworking.. Differences between collets and other holding devices..A lathe collet system is a special tool used in metalworking. It grips materials tightly and keeps them steady while you work. This helps make precise cuts. Collets are different from other holding devices, like chucks. They provide a better grip and are easier to use. Here are some key differences:

- Grip: Collets hold the workpiece securely without slipping.

- Speed: Collets allow for faster changes of tools.

- Precision: They offer a tighter fit for better accuracy.

Using a collet system can make your metalworking projects smoother and more efficient.

What are the advantages of using a collet system?

Collet systems are known for their strong grip, quick tool changes, and high precision. They help achieve cleaner cuts, which can improve the quality of your work.

Benefits of Using a Collet System

Increased precision and repeatability in machining.. Faster tool changes and setup times compared to traditional systems..Using a collet system brings some serious perks for anyone working with metal lathes. First off, it offers increased precision and repeatability. This means you won’t accidentally turn your masterpiece into a potato. Tool changes are quicker, too, which saves time. Imagine transforming from a wrench-wielding snail to a speedy rabbit! Let’s take a glance at the differences:

| Feature | Collet System | Traditional System |

|---|---|---|

| Precision | High | Moderate |

| Setup Time | Fast | Slow |

| Tool Changes | Quick | Time-Consuming |

With these advantages, a collet system truly makes the machining process a joyride!

Choosing the Right Collet for Your Metal Lathe

Factors to consider when selecting collets (size, material, application).. Recommendations for popular collet brands and models..Choosing the right collet can make a big difference in your metal lathe work. First, consider the size of the collet. It must match your workpiece. Next, think about the material. Different materials can affect durability and grip strength. Finally, check the application. Are you doing precision work or heavy-duty tasks? Popular brands like Sherline and ER collets are great choices.

What is the best collet for my project?

The best collet depends on your project needs. For small projects, a precision collet works best. For larger tasks, use a heavy-duty collet.

Key Factors to Consider

- Collet size: Match your workpiece.

- Material: Choose based on durability.

- Application: Select based on project type.

With these tips in mind, you can pick the right collet. Always remember, the right fit leads to better results.

Setting Up Your Lathe Collet System

Stepbystep guide to installing and setting up collets.. Common mistakes to avoid during setup..Before diving into your lathe collet system, make sure to gather your tools. First, fix the collet into the spindle. Make sure it’s snug but don’t turn it into the Hulk! Then, choose the right collet for your material. It’s like picking the right ice cream flavor—too soft, and things get messy!

Now, here’s a quick table of common mistakes to dodge:

| Mistake | Solution |

|---|---|

| Over-tightening collets | Just turn it until it feels right! |

| Using wrong size collet | Measure twice, cut once! |

| Skipping safety gear | Eye protection is cooler than you think! |

Follow these steps, avoid mistakes, and you’re on your way to becoming a lathe collet system pro! And remember, a perfect setup means smooth sailing—and less chance of your project flying off the rails like an over-caffeinated squirrel!

Maintenance Tips for Collet Systems

Best practices for cleaning and maintaining collets.. Signs of wear and when to replace collets..Keeping collet systems clean is key for smooth operation. Regularly wipe down your collets with a soft cloth to remove dust and grime. Don’t forget to check for any cracks or chips—those are signs it’s time to replace them! Replace collets if they don’t grip well or show significant wear. Remember, a happy lathe makes for a happier you! Here’s a quick reference table on maintenance:

| Maintenance Task | Frequency |

|---|---|

| Clean collets | After each use |

| Inspect for wear | Monthly |

| Replace worn collets | As needed |

A little maintenance goes a long way! Keep an eye out for those sneaky signs of wear, and your lathe will reward you with years of great service.

Applications of Lathe Collet Systems in Metalworking

Industries and projects that benefit from collet systems.. Case studies or examples of successful applications..Collet systems in metalworking are vital in different industries. These systems hold workpieces tightly, allowing precise machining. For example, automotive and aerospace sectors rely on them for safety and quality. Medical equipment manufacturers also use collets for accurate parts. A company creating custom engine parts saw a 30% efficiency boost after using collet systems. This highlights the importance of precision in various projects.

What industries use lathe collet systems?

Industries that benefit include automotive, aerospace, and medical manufacturing.Key Applications:

- Automotive industry

- Aerospace sector

- Medical equipment production

Advanced Techniques Using Collet Systems

Techniques to maximize efficiency and precision with collet systems.. Tips for specialized applications and materials..Using a collet system can really change the game for metal lathes. Collets hold workpieces tightly, ensuring high precision. This helps prevent any slipping. Want faster work? Try using different collet sizes. They help you adapt to various materials like wood or metals. If you’re turning something tricky, a collet keeps it snug. Remember, happy lathing means fewer mishaps, unless you count the occasional bad pun!

| Technique | Description |

|---|---|

| Size Matching | Use the right collet size for your material. |

| Adaptability | Switch collet types for specialized applications. |

Conclusion

In summary, a lathe collet system is essential for using a metal lathe effectively. It securely holds materials while you work, helping you make precise cuts. Understanding this gear can improve your projects significantly. We encourage you to explore how collet systems work and practice using one. You’ll gain valuable skills and confidence for your next metalworking project!FAQs

What Are The Advantages Of Using A Collet System Over A Three-Jaw Chuck On A Metal Lathe?Using a collet system is better than a three-jaw chuck for a few reasons. First, collets hold the workpiece more tightly. This means it won’t move while you’re working on it. Second, you can change pieces quickly with collets. Lastly, collets can hold smaller or odd-shaped items better than a three-jaw chuck. This helps you make more precise parts.

How Do You Properly Size And Choose Collets For Different Workpiece Diameters In A Lathe?To size and choose collets for a lathe, start by measuring your workpiece’s diameter. Collets come in different sizes, so pick one that matches the size of your workpiece. Make sure the collet can grip the workpiece tightly to hold it in place. If you’re working with multiple sizes, you might need different collets for each diameter. Always follow the manufacturer’s instructions to ensure safety and accuracy.

What Maintenance Practices Are Recommended For Ensuring The Longevity And Accuracy Of Lathe Collets?To keep lathe collets working well, you should clean them regularly. Use a soft cloth to wipe off dirt and chips. Check for signs of wear or damage, and replace them if needed. Always store them in a safe place to avoid dropping or bending them. Finally, apply a little oil to keep them smooth and working better.

Can You Explain How A Collet’S Design Affects Gripping Force And Precision In Turning Applications?A collet is a special tool that holds round items tightly while machines spin them. Its design has slits that allow it to squeeze the item more evenly. This even squeezing means we can grip things strongly without them slipping. When we have a strong grip, we can make precise cuts and shapes. So, a good design helps us work better and make nice, neat things!

What Are The Key Differences Between Er Collets, Rg Collets, And Other Collet Systems Used In Metalworking Lathes?ER collets are very popular because they hold tools tightly and fit many sizes. RG collets are also good but are better for specific tasks. Other collet systems can be less flexible and may only fit one tool size. In simple terms, ER collets are like a Swiss army knife, while RG collets are more like a single-use tool. Different collets help you work better with your metal lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over A Three-Jaw Chuck On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system is better than a three-jaw chuck for a few reasons. First, collets hold the workpiece more tightly. This means it won’t move while you’re working on it. Second, you can change pieces quickly with collets. Lastly, collets can hold smaller or odd-shaped items better than a three-jaw chuck. This helps you make more precise parts.”}},{“@type”: “Question”,”name”: “How Do You Properly Size And Choose Collets For Different Workpiece Diameters In A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To size and choose collets for a lathe, start by measuring your workpiece’s diameter. Collets come in different sizes, so pick one that matches the size of your workpiece. Make sure the collet can grip the workpiece tightly to hold it in place. If you’re working with multiple sizes, you might need different collets for each diameter. Always follow the manufacturer’s instructions to ensure safety and accuracy.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended For Ensuring The Longevity And Accuracy Of Lathe Collets? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep lathe collets working well, you should clean them regularly. Use a soft cloth to wipe off dirt and chips. Check for signs of wear or damage, and replace them if needed. Always store them in a safe place to avoid dropping or bending them. Finally, apply a little oil to keep them smooth and working better.”}},{“@type”: “Question”,”name”: “Can You Explain How A Collet’S Design Affects Gripping Force And Precision In Turning Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet is a special tool that holds round items tightly while machines spin them. Its design has slits that allow it to squeeze the item more evenly. This even squeezing means we can grip things strongly without them slipping. When we have a strong grip, we can make precise cuts and shapes. So, a good design helps us work better and make nice, neat things!”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Er Collets, Rg Collets, And Other Collet Systems Used In Metalworking Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “ER collets are very popular because they hold tools tightly and fit many sizes. RG collets are also good but are better for specific tasks. Other collet systems can be less flexible and may only fit one tool size. In simple terms, ER collets are like a Swiss army knife, while RG collets are more like a single-use tool. Different collets help you work better with your metal lathe.”}}]}