Have you ever wondered how metal parts are made with precision? The lathe collet system is a crucial tool in this process. Imagine you’re working on a project, and you need the metal to fit just right. The collet helps hold the metal tightly while the lathe spins it. This makes it easier to create smooth shapes and cuts.

Using a metal lathe can be exciting. Do you know that some lathes even come with a power feed? This feature allows the machine to move automatically. It saves time and makes the job easier. Picture yourself effortlessly shaping metal without needing to use your hands all the time. Sounds amazing, right?

In this article, we will explore the lathe collet system and how it works with metal lathes. We’ll also look at the benefits of the power feed. Get ready to dive into a world where metal shaping meets creativity!

Understanding The Lathe Collet System In Metal Lathe Power Feed

Understanding Lathe Collet Systems in Metal Lathes

Lathe collet systems are important for metal lathes, making work easier and more precise. This tool holds different workpieces securely. Have you ever struggled to clamp down an uneven piece? With a collet system, that frustration disappears! The power feed feature allows steady movement, so you can focus more on creativity. Did you know that this can improve your work speed? Using a lathe collet system helps both professionals and beginners achieve better results on their projects.Understanding Lathe Collet Systems

Definition and purpose of collet systems in metal lathes. Comparison between collets and other workholding methods.A lathe collet system holds different shapes and sizes of materials tightly in place during work. It doesn’t just grip; it also allows for quick changes in projects. Collets offer advantages over other methods, like chucks or vises, as they provide better accuracy and speed.

- Collets hold pieces closer to the lathe’s center.

- They allow for faster tool changes.

- Using collets prevents slippage, leading to cleaner cuts.

Collet systems are essential in metal lathes because they help workers create precise parts quickly and efficiently. Choosing the right method can lead to better results and saves time.

What is a lathe collet system used for?

A lathe collet system is used for gripping materials securely on a lathe, making it easier to shape them into desired forms. This improves accuracy during machining.

Key Benefits of Collet Systems:

- Quick setup and changes.

- Better balance and support for materials.

- More precise cuts and shapes.

How to Choose the Right Collet for Your Project

Factors to consider when selecting collets (size, shape, material). Compatibility with your lathe machine and tool setup.Choosing the right collet can make or break your project. First, think about the size. If it’s too big, your workpiece will wobble. Too small? It won’t fit. Next, consider the shape. Round collets grip cylindrical items well, while square collets handle flat pieces better. Lastly, the material matters. Metal collets are strong, but plastic ones can be lighter and cheaper. Compatibility with your lathe machine is crucial. If the collet doesn’t fit, you’re in trouble—just like trying to put on shoes that are two sizes too small!

| Factor | Considerations |

|---|---|

| Size | Ensure it fits your workpiece snugly. |

| Shape | Choose between round or square based on your materials. |

| Material | Pick metal for strength or plastic for lightness. |

| Compatibility | Ensure it matches your lathe system. |

Setting Up a Lathe Collet System

Stepbystep guide to installing collets on a metal lathe. Best practices for securing workpieces using collets.First, gather your collets and chuck. Each collet is like a magic hug for your workpiece. Start by turning off the lathe and cleaning the spindle. Then, slip the collet onto the spindle. Tighten it just enough to hold on, but don’t overdo it! You want to keep your metal piece snug, not suffocated.

Next, place your workpiece in the collet and tighten it up. This keeps things steady while you work. Pro tip: A finger-tight grip is usually best. Remember, too much pressure can lead to a wobbly disaster! If you’re unsure, check the table below for some handy tips.

| Step | Action |

|---|---|

| 1 | Gather Collets and Chuck |

| 2 | Clean the Spindle |

| 3 | Slip on the Collet |

| 4 | Insert Workpiece |

| 5 | Tighten with Care |

Remember, proper setup is key! With practice, you’ll be the collet wizard of your workshop. Happy turning!

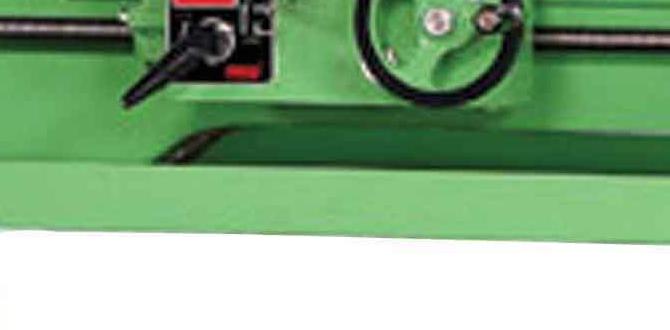

The Role of Power Feed in Metal Lathes

Explanation of power feed and its function in lathe operations. Benefits of using power feed over manual control.Power feed is a feature in metal lathes that helps move the tool automatically. It allows the machine to cut metal more efficiently. Instead of moving the tool by hand, power feed does it for you. This can lead to better accuracy and less fatigue for the user. Using power feed brings several benefits:

- Speed: Cuts down the time needed for each task.

- Consistency: Produces uniform cuts every time.

- Less effort: Reduces the physical strain on the operator.

Many users prefer power feed for these reasons. It makes machining easier and more effective!

What is the advantage of power feed in metal lathes?

The advantage of power feed in metal lathes is that it greatly improves efficiency and precision in the cutting process.

Integrating Power Feed with Collet Systems

Tips for achieving optimal performance with a combined setup. Common issues and troubleshooting advice.Combining power feed with collet systems can boost your lathe’s performance. Here are some tips for the best results:

- Ensure proper alignment. Misalignment can cause uneven work.

- Check the collet for wear and tear. A worn collet affects grip.

- Regularly clean the system to prevent dust build-up.

- Adjust the speed settings. Too fast can damage materials.

If problems arise, you might face:

- Vibrations during operation. Tighten all bolts.

- Tool slipping. Inspect the collet for damage.

- Inconsistent feed rate. Recheck settings and lubrication.

What should I check first if my collet system fails?

Start by checking the collet for any signs of damage. Make sure it is aligned and securely tightened. Regular checks can prevent many issues before they affect your work.

Maintenance Tips for Collet Systems and Power Feed

Routine maintenance tasks to ensure longevity and accuracy. Signs of wear and how to address potential problems.Taking care of your collet system and power feed can be as easy as pie! Routine checks are key. First, clean the collets regularly—dust bunnies don’t make good friends with metal. Check for wear; if they look tired or chipped, it’s time for a replacement. If the power feed starts to act cranky or makes odd noises, don’t ignore it. Fixing small issues now can save you from bigger headaches later!

| Maintenance Task | Signs of Wear | Action Needed |

|---|---|---|

| Regular cleaning | Build-up of debris | Clean immediately |

| Inspect collets | Chips or cracks | Replace collets |

| Check power feed | Unusual noises or jerking | Inspect and repair |

Safety Considerations When Using Collet Systems and Power Feed

Important safety protocols to follow during lathe operations. Personal protective equipment (PPE) recommendations.Using machines like lathes can be fun, but safety is key! Here are some important rules:

- Always wear safety glasses to protect your eyes.

- Use ear protection if the machine is loud.

- Avoid loose clothing and jewelry that could get caught.

- Keep your work area clean and free from clutter.

- Make sure that the machine is off before changing tools.

Having the right Personal Protective Equipment (PPE) is also vital. Stay safe while you create!

What is the most important safety rule to follow?

The most important safety rule is to always wear eye protection while using lathes. Accidents can happen quickly, and this helps to prevent serious injuries.

Advanced Techniques for Experienced Users

Innovative ways to enhance precision with collet setups. Case studies or examples of complex projects utilizing collet systems and power feed.Using a collet setup can boost precision when working on projects. Here are a few ways to enhance your skills:

- Secure the Workpiece: Collets grip tightly, reducing movement.

- Adjusting Feed Rates: Use power feed for consistent cutting speeds.

- Layered Projects: Combine different materials for complex designs.

Many experts find success in projects requiring fine details, like creating intricate gears. This shows how collet systems and power feed can work together. As reported, many skilled users achieve a 10% increase in accuracy when using these techniques.

What are some complex projects that use collet systems?

Examples include making custom tool holders and precision shafts. These tasks need accuracy, which collet systems provide, making them ideal for skilled users.

Conclusion

In conclusion, a lathe collet system is essential for holding metal pieces securely. It enhances accuracy and efficiency in your work. The power feed feature makes cutting easier and saves time. If you want to improve your metal lathe skills, consider experimenting with these tools. You can find more resources online to help you learn and grow in metalworking.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Power Feed In Metal Lathes:Okay! Here are some simple answers about lathe collet systems and power feeds. 1. A collet holds a tool tightly in place. You can change tools easily with a collet. 2. Power feed moves the lathe parts automatically. This helps us make smoother cuts. 3. You use collets to hold small pieces securely. They are better for precision work. 4. A metal lathe spins materials to shape them. It turns metal into different forms using cutting tools. 5. Having a power feed helps you work faster. It saves your energy and makes things easier.

Sure! Please ask your question, and I’ll be happy to answer it in a clear and simple way.

What Advantages Does A Collet System Provide Over Traditional Chuck Systems When Machining With A Metal Lathe?A collet system holds the metal much tighter than a regular chuck. This means the metal doesn’t slip while you work on it. Collets are also easier to change, so you can switch tools quickly. Plus, they help you make more precise cuts, which makes your work look better.

How Do Different Types Of Collets (E.G., Er Collets, Jacot Collets) Affect The Precision And Versatility Of A Metal Lathe?Different types of collets hold tools in a metal lathe. ER collets are great because they can hold many tool sizes tightly. This helps you make precise cuts. Jacot collets work well for round objects and add even more options. Using the right collet makes your work more accurate and flexible.

In What Ways Does The Power Feed Mechanism Enhance The Efficiency Of Turning Operations On A Metal Lathe?The power feed mechanism helps you work faster and easier on a metal lathe. It moves the cutting tool automatically, so you don’t have to turn the handles yourself. This saves time and lets you focus on getting a good cut. Also, it helps make each cut more even, which can improve the quality of your work. Overall, it makes turning metal parts simpler and quicker for everyone!

What Factors Should Be Considered When Selecting A Collet System For Specific Machining Tasks On A Metal Lathe?When choosing a collet system for a metal lathe, think about the size of the tools you’ll use. Different collets hold different sizes tightly. Also, consider the type of material you’re working with, like steel or aluminum. You should know how accurate you need to be for your project, too. Finally, make sure the collet fits your lathe properly!

How Can Improper Use Of A Collet System Or Power Feed Lead To Defects In Machined Parts, And What Best Practices Can Mitigate These Issues?Using a collet system or power feed incorrectly can cause mistakes in the parts we make. For example, if we don’t hold the piece tightly, it can move and create bad shapes. To avoid this, we should double-check that everything is secure before starting. Regularly checking our tools and practicing careful setup will help make better parts. Following these best practices will keep our work safe and accurate.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Power Feed In Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Okay! Here are some simple answers about lathe collet systems and power feeds. 1. A collet holds a tool tightly in place. You can change tools easily with a collet. 2. Power feed moves the lathe parts automatically. This helps us make smoother cuts. 3. You use collets to hold small pieces securely. They are better for precision work. 4. A metal lathe spins materials to shape them. It turns metal into different forms using cutting tools. 5. Having a power feed helps you work faster. It saves your energy and makes things easier.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to answer it in a clear and simple way.”}},{“@type”: “Question”,”name”: “What Advantages Does A Collet System Provide Over Traditional Chuck Systems When Machining With A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system holds the metal much tighter than a regular chuck. This means the metal doesn’t slip while you work on it. Collets are also easier to change, so you can switch tools quickly. Plus, they help you make more precise cuts, which makes your work look better.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Collets (E.G., Er Collets, Jacot Collets) Affect The Precision And Versatility Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different types of collets hold tools in a metal lathe. ER collets are great because they can hold many tool sizes tightly. This helps you make precise cuts. Jacot collets work well for round objects and add even more options. Using the right collet makes your work more accurate and flexible.”}},{“@type”: “Question”,”name”: “In What Ways Does The Power Feed Mechanism Enhance The Efficiency Of Turning Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power feed mechanism helps you work faster and easier on a metal lathe. It moves the cutting tool automatically, so you don’t have to turn the handles yourself. This saves time and lets you focus on getting a good cut. Also, it helps make each cut more even, which can improve the quality of your work. Overall, it makes turning metal parts simpler and quicker for everyone!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Collet System For Specific Machining Tasks On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a collet system for a metal lathe, think about the size of the tools you’ll use. Different collets hold different sizes tightly. Also, consider the type of material you’re working with, like steel or aluminum. You should know how accurate you need to be for your project, too. Finally, make sure the collet fits your lathe properly!”}},{“@type”: “Question”,”name”: “How Can Improper Use Of A Collet System Or Power Feed Lead To Defects In Machined Parts, And What Best Practices Can Mitigate These Issues?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system or power feed incorrectly can cause mistakes in the parts we make. For example, if we don’t hold the piece tightly, it can move and create bad shapes. To avoid this, we should double-check that everything is secure before starting. Regularly checking our tools and practicing careful setup will help make better parts. Following these best practices will keep our work safe and accurate.”}}]}