Have you ever watched a metal lathe in action? It’s fascinating! You might wonder how it shapes metal into amazing projects. The secret often lies in the lathe collet system. This simple tool helps hold pieces in place tightly. It gives you better control over your work.

Imagine crafting a beautiful vase or a precise gear. Every metal lathe project can shine with the right techniques. Using a collet system, you can create stunning designs with ease. Have you thought about what you could build? The possibilities are endless!

In this article, we will explore different metal lathe projects. You’ll learn how to use the lathe collet system like a pro. Get ready to dive into the exciting world of metalworking! Your next project might just be a few steps away.

Lathe Collet System For Metal Lathe Projects: A Guide

Lathe Collet System for Metal Lathe Projects

Do you want to improve your metal lathe projects? A lathe collet system can offer better precision. Collets hold workpieces tightly, making it easier to create intricate designs. Imagine creating a perfect part for a robot or a model car. With a collet, the chances of error decrease. This tool allows you to work on various materials and shapes effortlessly. Start using a lathe collet system and unlock new possibilities in your metalworking adventures!Understanding Lathe Collet Systems

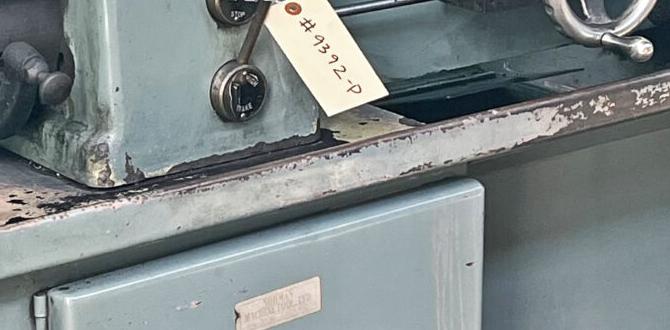

Definition and purpose of lathe collet systems. How collets differ from other workholding methods.Think of a lathe collet system as a superhero for your metal parts! It holds workpieces with a tight grip, ensuring they stay in place while you work. Unlike other methods like chucks, which can be bulky, collets are sleek and do the job perfectly. They are great for quick changes between projects. Plus, we can all agree that less fuss means more fun, right?

| Workholding Method | Grip Strength | Speed of Change |

|---|---|---|

| Collet | Strong | Fast |

| Chuck | Moderate | Slower |

So next time you’re spinning metal, remember: collets are like the trusty sidekick who always has your back.

Benefits of Using a Lathe Collet System

Enhanced precision and repeatability in projects. Increased versatility for various metal lathe applications.Using a lathe collet system is like having a magic wand for your metal lathe projects! It makes your work super precise and repeatable. Imagine being able to create the same part over and over with pinpoint accuracy—no more guesswork! Plus, this system opens up a world of possibilities. You can tackle many different applications with ease. So, whether you’re making tiny screws or big parts, you’ll have the right grip for the job. Talk about versatile!

| Benefit | Description |

|---|---|

| Precision | Improves accuracy in every cut. |

| Versatility | Handles a wide range of tasks. |

Choosing the Right Collet for Your Project

Factors to consider: size, shape, and material compatibility. Recommendations for common metal lathe projects.Picking a collet for your metal lathe project can be tricky, but it’s not rocket science. First, think about the size—your collet should snugly fit the workpiece. Next, consider the shape. Some shapes are better for certain tasks, like round for general use and square for more exact jobs. Lastly, don’t forget material compatibility. Using the wrong material can ruin your project! Here’s a quick guide:

| Collet Type | Best For | Material |

|---|---|---|

| 3-Jaw Chuck | General purpose | Steel, Aluminum |

| 4-Jaw Chuck | Precision work | Steel, Brass |

| Collet Chuck | High precision | All types |

Choose wisely, and your lathe project will be smoother than a cat on a freshly waxed floor!

Setting Up Your Lathe Collet System

Stepbystep guide to installing and aligning collets. Safety tips for operating the lathe with a collet system.First things first, get your collet ready. Place it in the spindle using a gentle twist—like you’re putting on a snug glove. Next, tighten it up like you’re securing the last cookie from the jar. Now, let’s align it! Turn on the lathe and run a test piece. Is it spinning like a top? Great! If it wobbles, adjust until it’s straight.

Safety comes first. Always wear eye protection. It’s better to look silly than risk an eye. Keep loose clothes away; no one wants to wear a lathe sweater! Use the right speed for your project. Too fast can turn your lathe into a tornado.

| Tip | Description |

|---|---|

| Eye Protection | Wear goggles to keep your eyes safe! |

| Clothing | Tie back long hair and avoid loose sleeves. |

| Speed Control | Adjust speed for the best results. |

Popular Metal Lathe Projects Using Collet Systems

Project ideas: precision shafts, custom fittings, and specialized tools. Tips for tackling complex designs with collet systems.Many fun projects can be made using a lathe collet system. Here are some popular ideas:

- Precision shafts: Create exact sizes for any purpose.

- Custom fittings: Make parts that fit your specific needs.

- Specialized tools: Build tools for unique tasks.

For complex designs, focus on these tips:

- Start with a simple sketch.

- Measure everything carefully.

- Test your collet system regularly.

Using a collet system can make your projects easier and more fun!

What are some examples of projects?

Examples include precision shafts for mechanical devices and custom fittings for unique projects.

Maintaining Your Lathe Collet System

Regular maintenance tasks to ensure longevity. Troubleshooting common issues with collet systems.To keep your lathe collet system in good shape, regular maintenance is key. Simple tasks help everything last longer and work better. Check for dirt and debris often. Clean the collet regularly to prevent rust. Lubricate moving parts to keep them smooth. If you notice a problem, tackle it early.

- Make sure the collet fits tight.

- Watch for wear on parts.

- Listen for unusual sounds.

If issues arise, fixing them quickly can save time and money. Always check your collet system before starting a new project.

What are the common problems with collet systems?

Common issues include: loose fits, excessive wear, and unusual noises. Regular checks can spot these problems early.

Quick fixes for collet issues:

- Tighten loose fittings.

- Replace worn parts.

- Inspect and clean regularly.

Resources and Accessories to Enhance Your Lathe Projects

Recommended tools and materials for successful projects. Online forums and communities for lathe enthusiasts.Starting a lathe project? Having the right tools makes all the difference. You’ll need sturdy lathe collets for precision work and a variety of materials like metals and woods to keep things interesting. Don’t forget to check out online forums! They’re packed with friendly folks ready to share tips and tricks. Plus, you might find a funny story about a lathe mishap that makes you chuckle. Here’s a quick table of must-have tools:

| Tool | Purpose |

|---|---|

| Lathe Collets | Secure your workpiece tightly |

| Carbide Bits | Shape and cut materials |

| Tool Holder | Keep your bits organized |

Conclusion

In conclusion, a lathe collet system is essential for metal lathe projects. It offers precise holding of materials, making your work easier. Whether you are a beginner or experienced, using this system improves your results. We encourage you to explore more about collets and try some practical projects. Start your journey today and enhance your metalworking skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Projects:Sure! A lathe is a tool that helps us shape metal. Collets are special parts that hold the metal tight. When working on projects, we use lathes to cut and shape the metal into designs. It’s fun to create things, and we learn a lot while doing it!

Sure! Please provide the question you want me to answer.

What Are The Advantages Of Using A Collet System Versus A Three-Jaw Chuck In Metal Lathe Projects?Using a collet system is often better than a three-jaw chuck when working on a metal lathe. Collets grip round pieces tighter and more evenly. This means less chance of things slipping or getting damaged. You can also change pieces faster with collets. Overall, they help you do better work more easily.

How Do You Choose The Appropriate Collet Size And Type For Specific Metal Lathe Applications?To choose the right collet size for your metal lathe, start by checking the size of the material you want to hold. Measure it carefully, so you know what size you need. Next, think about the type of work you are doing. Some collets hold round shapes better, while others can grip different shapes. Finally, make sure the collet fits your lathe properly for safe and smooth work.

What Are Some Common Materials And Techniques Used For Custom Lathe Projects That Utilize Collet Systems?For custom projects using collet systems, we often use materials like wood, metal, and plastic. These materials are easy to shape on a lathe, which is a tool that spins the material to help us cut it. We typically use techniques like turning, where we make round shapes, and sanding, which smooths everything out. Collet systems hold the material tightly while we work, making it safer and easier. Using these materials and techniques can help you create cool and smooth objects!

How Can Precision Be Improved When Machining Small-Diameter Parts Using A Collet System On A Metal Lathe?To improve precision when using a collet system on a metal lathe, you can start by using the right size collet. Make sure the collet fits your small-diameter part closely. You should also check that the lathe is set up correctly and aligned. Use a slow speed when cutting to get a better finish. Finally, keep your tools sharp to help make clean cuts.

What Are The Best Practices For Maintaining And Troubleshooting Collet Systems In A Metal Lathe Setup?To keep your collet system working well, check it regularly. Make sure the collets are clean and free of dust. If something doesn’t fit right, try tightening or loosening it. Always replace worn-out parts to avoid problems. Lastly, follow the equipment instructions for safe usage.