Have you ever marveled at how machines shape metal? A lathe is a key player in that world. With its unique features, it can turn raw metal into precise parts. But did you know the lathe collet system makes this job even easier?

Imagine you’re in a workshop, ready to create something amazing. You need the right tool to hold your metal tight. That’s where the collet system comes in! It grips the metal securely, helping you work with precision.

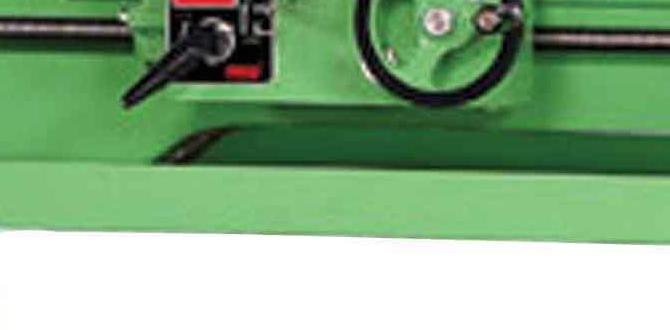

Now, picture the smooth operation of a metal lathe pulley. It helps keep everything moving as you work. This simple yet clever part of the machine can make a big difference. It ensures that the lathe runs smoothly, giving you the best results possible.

In this article, we’ll explore how the lathe collet system and metal lathe pulley work together. You’ll learn how they make metalworking easier and more fun. Ready to dive in? Let’s get started!

Understanding Lathe Collet System And Metal Lathe Pulley

Lathe Collet System Metal Lathe Pulley

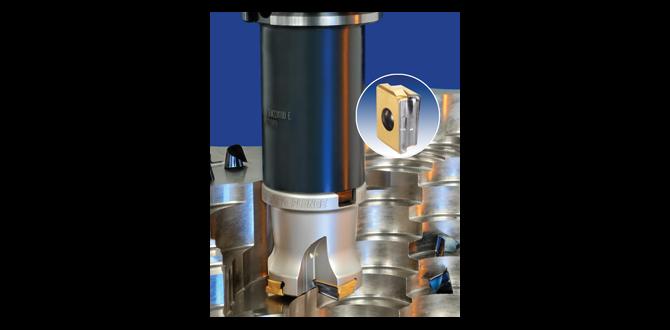

The lathe collet system is a game-changer for metalworking. It holds tools securely, making it easier to create precise cuts. Have you ever struggled with tool slippage? This system prevents that. With a metal lathe pulley, you gain control over spindle speed, enhancing your project quality. Did you know a simple change to this setup can save time and improve outcomes? A well-structured lathe setup means better projects every time! Consider upgrading your tools for amazing results.What is a Lathe Collet System?

Definition and purpose of a lathe collet system. Types of collets used in metal lathes.A lathe collet system holds tools and workpieces tightly in place. It uses a special clamp called a collet to do this. The main purpose is to make sure everything spins smoothly and safely. There are different types of collets used in metal lathes:

- Taper Collets: They fit into the machine securely.

- Hex Collets: These hold hex-shaped tools.

- Waisted Collets: They are perfect for irregular shapes.

Using the right collet makes turning and shaping metal easier. It improves accuracy and efficiency!

What types of collets are used in metal lathes?

Common types of collets include: Taper, Hex, and Waisted collets. Each type serves a specific purpose for different tools.

Benefits of Using a Collet System in Metal Lathes

Increased precision and accuracy in machining. Enhanced workholding capabilities for various materials.A collet system in metal lathes offers impressive benefits. First, it increases precision and accuracy in machining. This means your work can be more detailed and exact. Second, it improves workholding capabilities. It can hold different materials better than regular clamps.

- Better fit for various shapes

- Firm grip for safe machining

- Easy to switch between materials

With these advantages, you can create better projects with less hassle.

How does a collet system improve precision?

A collet system improves precision by gripping materials tightly and evenly, reducing movement during machining. This leads to smoother cuts and better finished pieces.

Components of a Lathe Collet System

Description of collets, adapter sleeves, and nuts. How each component contributes to the overall function.A lathe collet system has three main parts: collets, adapter sleeves, and nuts. Each part plays a special role. Collets hold the workpiece tightly in place. They provide a strong grip, making sure everything stays steady during work. Adapter sleeves connect the collets to the lathe. They help fit different sizes easily. Finally, nuts secure the entire setup. They keep everything snug, preventing any movement. Together, these components make the lathe function smoothly and efficiently.

What is a collet?

A collet is a clamp or holder that grips the workpiece tightly. It helps in making precise cuts.

What do adapter sleeves do?

- Adapter sleeves connect collets to the lathe.

- They allow for easy size adjustments.

How do nuts work in this system?

Nuts keep everything tight. They ensure that the collet and workpiece do not move while lathe operates.

Choosing the Right Collet for Your Metal Lathe

Factors to consider when selecting collets. Common size types and their applications.Picking the right collet for your lathe is very important. There are some key things to think about:

• Size: Make sure it matches your lathe.

• Type: Different tasks need different collet types.

• Material: Stronger materials last longer.

Common sizes include:

• 1/8 inch for small projects.

• 1/4 inch for medium jobs.

• 1/2 inch for large tasks.

What should I consider when choosing a collet?

Think about size, type, and material for the best fit.

Integrating Collet Systems with Pulley Operations

How collet systems work with pulleys in metal lathes. Maintenance tips for optimizing performance.Collet systems are like the trusty sidekick to the heroic pulley in metal lathes. They hold tools tightly during spinning, preventing any mishaps. The magic happens when these systems connect to pulleys to ensure smooth operations. Want to keep your lathe happy? Regular maintenance is key! Check for wear and tear, and keep everything clean. A well-oiled lathe is a happy lathe. Remember, “A pinwheel’s only as good as its spin!”

| Maintenance Tips | Benefits |

|---|---|

| Regularly inspect collets | Prevent tool slippage |

| Keep pulleys lubricated | Smoother operation |

| Clean debris regularly | Longer service life |

Common Issues and Troubleshooting in Collet Systems

Identifying and resolving common problems. Best practices for avoiding issues.Issues with collet systems can pop up like a surprise exam! Common problems include *misalignment*, *wear and tear*, and *chip buildup*. Luckily, spotting these is easier than finding a needle in a haystack. Keep an eye out for loose collets or vibrations. Regular cleaning can save the day. Check the table below for quick fixes and best practices!

| Problem | Solution |

|---|---|

| Misalignment | Adjust the setup to ensure a snug fit. |

| Worn collets | Replace your collets often, like fresh socks! |

| Chip buildup | Clean regularly to keep things running smoothly. |

Following these tips will keep your metal lathe humming like a happy bee!

Future Trends in Lathe Collet Technology

Innovations in collet design and functionality. Potential advancements in metal lathe pulley systems.New designs in collets are helping metalworkers. These innovations make it easier to hold different tools securely. Users can change tools faster, which saves time. Also, some collets now have special features to prevent slipping. This means more precise work.

As for metal lathe pulley systems, there are exciting changes coming. Engineers are exploring lightweight materials, making them more efficient. This can lead to smoother operation and less wear over time.

- Stronger materials for better durability.

- Smart technology for easier setups.

- More options for different projects.

What are the benefits of new collet technology?

New collet technology offers better grip and faster tool changes. It also improves overall precision in metalworking, making tasks easier and quicker.

Conclusion

In summary, a lathe collet system is essential for securing workpieces on metal lathes. It offers better precision than standard chucks. A metal lathe pulley helps control speed and torque, making your projects easier. We encourage you to learn more about these tools and try using them in your next project. Understanding these systems will improve your machining skills!FAQs

What Are The Advantages Of Using A Collet System In A Metal Lathe Compared To Traditional Chuck Systems?Using a collet system in a metal lathe has some cool benefits. First, it holds the metal piece really tightly, so it won’t move around. Second, it’s easier to change pieces quickly when you need to. Third, collets can hold small and odd-shaped items better than regular chucks. This makes your work faster and more precise!

How Does The Pull-Down Mechanism In A Lathe Collet System Work To Secure Workpieces Effectively During Machining?A lathe collet system holds workpieces using a special clamp. When you pull down a lever, it tightens the collet around the piece. This makes sure the workpiece stays in place while the machine works. The tight grip helps prevent slipping, so the cutting tool can do its job well. This way, your workpiece is safe and secure!

What Types Of Materials Are Typically Used In The Construction Of Lathe Collets And Pulleys, And How Do These Materials Impact Performance?Lathe collets and pulleys are usually made from metals like steel or aluminum. Steel is very strong and lasts a long time. Aluminum is lighter, which can help machines work faster. The material you choose can change how well these tools perform in your projects.

Can You Explain The Process Of Selecting The Appropriate Collet Size For A Specific Lathe Application?To pick the right collet size for your lathe, you first need to know the size of the piece you want to hold. Measure the diameter of your workpiece carefully. Next, look at the collet sizes available for your lathe. Choose a collet that matches your measurement closely. Finally, fit the collet onto the lathe, and make sure it holds your workpiece tightly!

What Maintenance Practices Are Recommended For Ensuring The Longevity And Accuracy Of Lathe Collet Systems And Pulleys?To keep lathe collet systems and pulleys working well, you should clean them regularly. Dust and chips can get stuck in the machine, so wipe them down. Check for any loose parts and tighten them if needed. Lubricate the moving parts to help them run smoothly. Lastly, store them properly when not in use to prevent damage.