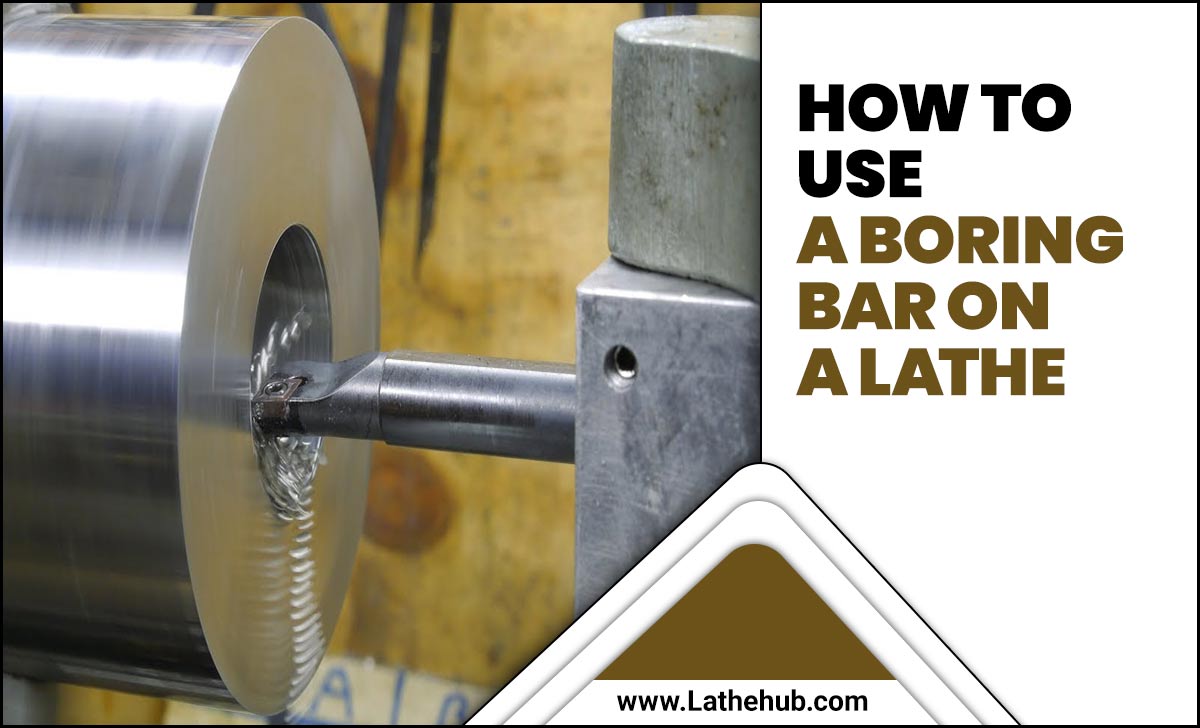

Have you ever wondered how metal pieces are shaped and formed? It’s fascinating to think about the tools that make this happen. One important tool is the metal lathe.

A lathe collet system plays a key role in this process. It holds the workpiece tightly while it spins. This allows for precise cuts and smooth finishes. Imagine creating a perfectly round metal part in just minutes! With a sturdy lathe stand, users can easily operate their machines without worry.

Did you know that using a solid lathe stand can improve your work quality? It keeps the lathe stable, which is vital when crafting intricate designs. Think of it like a strong foundation for a house. Without it, the whole structure may crumble.

In this article, we’ll explore the benefits of a lathe collet system and the ideal metal lathe stand. By the end, you’ll understand why these components are so important in the world of machining. Are you ready to dive in and see how they can enhance your projects? Let’s get started!

Understanding The Lathe Collet System For Metal Lathe Stand

Lathe Collet System Metal Lathe Stand

The lathe collet system makes metalworking easier and more efficient. Imagine smoothly gripping your workpiece without slipping. This system uses special collets that clamp down tightly, keeping everything in place. A strong metal lathe stand supports your lathe, giving you stability for precise cuts. Did you know that a sturdy stand can reduce vibrations significantly? Choosing the right setup can help you create better projects and enjoy woodworking even more!Benefits of Using a Collet System with Metal Lathes

Improved accuracy and precision in machining. Enhanced stability and reduced tool chatter during operation.Using a collet system with metal lathes has great benefits. First, it helps to create improved accuracy and precision during machining. This means parts fit together better. Also, it provides enhanced stability, which reduces tool chatter. Less chatter means smoother cuts and better surfaces. You can get high-quality results faster.

Why is a collet system important?

A collet system allows for stronger grips on materials, reducing mistakes and enhancing overall performance.

Key Benefits:

- Better precision in cutting

- Less vibration during operation

- Faster and easier changes between tasks

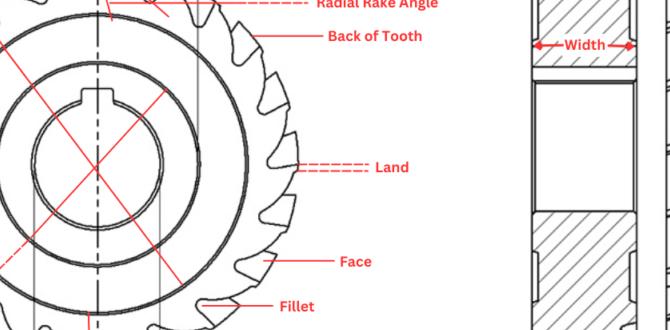

Components of a Lathe Collet System

Detailed breakdown of key components: collet, chuck, and spindle. Explanation of how these components work together.The lathe collet system has three important parts: the collet, chuck, and spindle. Each has a special job that works together to make everything run smoothly.

- Collet: This holds the tool or the workpiece tightly. It fits snugly, making sure it doesn’t move while the lathe spins.

- Chuck: This part holds the collet and secures it in place. It can hold different shapes and sizes.

- Spindle: This is the part that spins. It drives the collet and chuck, helping them work together.

By working together, these components help shape metal with precision. For example, they allow the lathe to turn a simple piece of metal into a beautiful sculpture or useful tool.

How do these components work together?

Each part plays a role. The spindle spins, moving the chuck and collet. The collet holds the tool tightly, keeping it stable. This teamwork creates perfect shapes and smooth finishes.

Choosing the Right Collet for Your Metal Lathe

Factors to consider when selecting a collet (size, material, application). Comparison of popular collet types.Selecting the perfect collet for your metal lathe can be a fun challenge, much like choosing the right ice cream flavor—there’s a lot to think about! First, consider the size of the collet. It needs to fit your workpiece snugly. Next, think about the material. Different materials handle heat and stress in unique ways, kind of like superheroes with special powers! Finally, match the collet to your application—is it for precision work or heavy-duty tasks? Here’s a quick comparison of popular collet types:

| Collet Type | Material | Best For |

|---|---|---|

| Hex Collet | Steel | General use |

| ER Collet | Aluminum | High precision |

| 3-Jaw Chuck | Cast Iron | Heavy-duty |

Choosing wisely means more successful projects and fewer “oops” moments!

Setting Up a Collet System on Your Metal Lathe Stand

Stepbystep guide to installing a collet system. Common challenges and troubleshooting tips.Installing a collet system can be as easy as pie—if you’re ready for the challenge! First, gather your tools and clean your workspace. Next, follow these steps:

- Measure the spindle, ensuring the collet fits snugly.

- Attach the collet closer to your lathe, using bolts for a secure hold.

- Insert the collet and adjust it until it clicks.

- Test with a sample piece to check how well it grips.

Some common hiccups are usually related to misalignment or a wobbly fit. If it doesn’t hold tight, give it a gentle twist or check for damages.

| Challenge | Solution |

|---|---|

| Collet won’t fit | Check size and clean the spindle. |

| Inconsistent grip | Look for wear or damage on the collet. |

Simple fixes can save you time and help you avoid pulling your hair out!

Maintenance and Care for Collet Systems

Best practices for cleaning and maintaining collets. Signs that a collet needs to be replaced.Keeping collets clean is like giving them a spa day. Wipe them with a soft cloth to remove dirt and grime. A little oil can work wonders, too! If you see cracks or bends, it’s time to let them go—think of it as a friendship that has run its course. Keep an eye out for these signs that a collet needs replacing:

| Signs of Wear | Action |

|---|---|

| Visible damage | Replace immediately! |

| Slipping workpieces | Time for a new collet. |

| Poor grip | Help your lathe, replace it! |

By keeping your collet systems well-maintained, you ensure your metal lathe stand runs smoothly. That’s a win for your projects and your sanity!

Collet System Accessories You Should Consider

Useful accessories to enhance lathe operation. Recommendations for specialized tooling.Every metal lathe master needs a few secret weapons to boost their game. First up, collet wrenches make changing tools a breeze. You won’t fumble with those tiny parts anymore! Tool holders are next. They keep your tools safe and organized, so you save time looking for them. And let’s not forget about the importance of a good, steady lathe stand. It keeps everything sturdy, just like a good pair of shoes! Here’s a quick table of must-have accessories:

| Accessory | Purpose |

|---|---|

| Collet Wrench | Quick tool changes |

| Tool Holder | Organizes tools |

| Lathe Stand | Stability and support |

With these handy accessories, happy lathe-ing is a piece of cake! Or maybe a piece of metal, which is less tasty but way more fun!

Safety Considerations When Using Collet Systems

Essential safety tips for operating lathe collet systems. Personal protective equipment (PPE) recommendations.Using lathe collet systems can be fun, but safety should come first. Always wear your Personal Protective Equipment (PPE), like goggles and gloves, to protect yourself from flying debris. Keep long hair tied back, and let loose clothing take a break. Remember, your fingers are not tools—they shouldn’t be near moving parts! Here’s a quick checklist:

| Safety Tip | Why It Matters |

|---|---|

| Wear goggles | Protects eyes from sparks |

| Use gloves | Safeguards hands from cuts |

| Tie back hair | Prevents hair from getting caught |

| Keep workspace clean | Avoids trips and falls |

Follow these tips and your collet system will be a safer place to work. Remember, safety first means fun second! And no one wants to explain to their mom why they have a bandage on their finger!

Conclusion

In summary, a lathe collet system helps hold metal pieces securely while you work. Choosing the right metal lathe stand is crucial for stability and safety. Understanding these tools will improve your projects. We encourage you to explore more resources to learn how to use these systems effectively. Remember, practice makes you better! Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Stands:Sure! A lathe collects tools and helps shape metal. We use a stand to keep the lathe steady. Collets are special tools that hold different shapes of metal tightly. They help us create precise work. A good stand makes it easier to use the lathe safely.

Sure! Just let me know what question you want me to answer, and I’ll help you out!

What Is A Collet System And How Does It Differ From A Traditional Chuck In A Metal Lathe?A collet system is a special tool used in a metal lathe. It holds small pieces of metal tightly. Unlike a traditional chuck, which grabs the outside, a collet grips the inside. This gives a better fit and helps keep the piece centered. You can change pieces quickly, which makes work easier!

What Are The Advantages Of Using A Collet System For Workholding In A Lathe Setup?Using a collet system on a lathe helps hold your workpiece tightly. This way, it won’t move while you work. Collets fit different shapes and sizes, so you can change pieces easily. You get good accuracy, which means your work is more precise. Plus, it saves time because it’s quick to set up.

How Do You Select The Appropriate Collet Size And Type For Specific Machining Tasks?To pick the right collet size, you first check what tool you are using. Each tool fits into a certain size collet. You also need to know what material you are working with. Some collets work better with specific materials. Finally, choose the type of collet that matches your machine’s needs.

What Features Should Be Considered When Designing Or Choosing A Stand For A Metal Lathe?When designing or choosing a stand for a metal lathe, think about strength. The stand must hold the lathe steady and not wobble. You should also consider the height. It needs to be comfortable for you to work on. Lastly, make sure there’s space for tools and materials around it.

How Can The Stability And Alignment Of A Lathe Stand Impact The Overall Performance Of The Lathe And Workpiece Accuracy?The stability of a lathe stand keeps the machine from shaking. When the lathe is steady, it cuts smoothly. If the stand is misaligned, it can make the workpiece uneven and messy. We want the lathe to be well-balanced to make better shapes and sizes. A strong, straight stand helps you create perfect pieces every time.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Stands:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe collects tools and helps shape metal. We use a stand to keep the lathe steady. Collets are special tools that hold different shapes of metal tightly. They help us create precise work. A good stand makes it easier to use the lathe safely.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer, and I’ll help you out!”}},{“@type”: “Question”,”name”: “What Is A Collet System And How Does It Differ From A Traditional Chuck In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system is a special tool used in a metal lathe. It holds small pieces of metal tightly. Unlike a traditional chuck, which grabs the outside, a collet grips the inside. This gives a better fit and helps keep the piece centered. You can change pieces quickly, which makes work easier!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System For Workholding In A Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system on a lathe helps hold your workpiece tightly. This way, it won’t move while you work. Collets fit different shapes and sizes, so you can change pieces easily. You get good accuracy, which means your work is more precise. Plus, it saves time because it’s quick to set up.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Collet Size And Type For Specific Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To pick the right collet size, you first check what tool you are using. Each tool fits into a certain size collet. You also need to know what material you are working with. Some collets work better with specific materials. Finally, choose the type of collet that matches your machine’s needs.”}},{“@type”: “Question”,”name”: “What Features Should Be Considered When Designing Or Choosing A Stand For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing or choosing a stand for a metal lathe, think about strength. The stand must hold the lathe steady and not wobble. You should also consider the height. It needs to be comfortable for you to work on. Lastly, make sure there’s space for tools and materials around it.”}},{“@type”: “Question”,”name”: “How Can The Stability And Alignment Of A Lathe Stand Impact The Overall Performance Of The Lathe And Workpiece Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The stability of a lathe stand keeps the machine from shaking. When the lathe is steady, it cuts smoothly. If the stand is misaligned, it can make the workpiece uneven and messy. We want the lathe to be well-balanced to make better shapes and sizes. A strong, straight stand helps you create perfect pieces every time.”}}]}