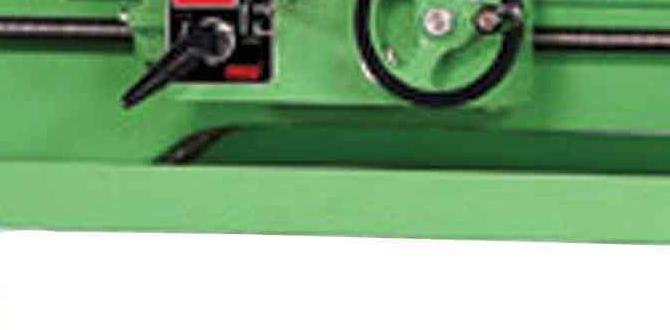

If you’ve ever watched a lathe in action, you know how amazing it can be. Imagine turning raw metal into a perfect shape with just a few simple steps. Have you ever wondered how those skilled workers achieve such precision?

One key to their success lies in the lathe collet system. This handy tool helps hold the metal firmly in place while it spins. Using a lathe collet system simplifies jobs like thread cutting. It allows the cutting tool to create clean and accurate threads without slipping.

Did you know that the right collet can make a world of difference? A well-fitted lathe collet holds the piece tightly, preventing mistakes. This is especially important for metal lathe thread cutting, where precision matters most.

Let’s explore the fascinating world of lathe collet systems and see how they work. You might just discover a new appreciation for this essential tool!

Lathe Collet System For Metal Lathe Thread Cutting Explained

Understanding the Lathe Collet System for Metal Lathe Thread Cutting

The lathe collet system is key for effective thread cutting on metal lathes. It securely holds workpieces, preventing slips while you cut. Have you ever struggled to secure a piece without wobbling? With a collet, that worry disappears. Did you know that collets come in different sizes? This means you can tackle various projects with ease. Using the right collet system can greatly improve your accuracy and finish. Take your metalworking skills to the next level!What is a Lathe Collet System?

Definition and purpose of a collet system in metalworking. Types of collets and their applications.A lathe collet system is a clever tool used in metalworking. It securely holds the workpiece while the lathe spins it. This is like a strong handshake when you meet someone new—firm and dependable!

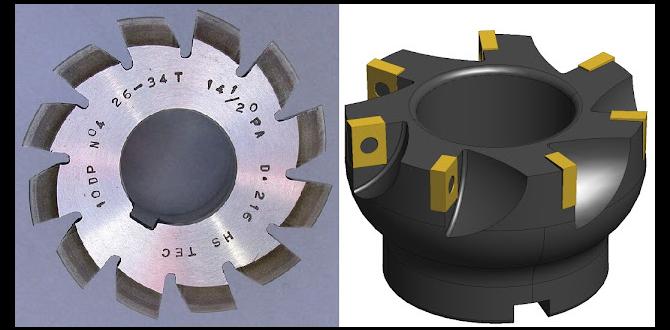

There are different types of collets, each with its own special job. For example, three-jaw collets can grab items from three points, making them great for round pieces. Sometimes, you need something different. Then you can use square collets for things with edges.

| Collet Type | Application |

|---|---|

| Three-Jaw Collet | Ideal for round workpieces |

| Square Collet | Perfect for square or flat items |

| Hex Collet | Used for hexagonal shapes |

Using the right collet is like choosing the perfect ice cream flavor, you want what fits best!

Benefits of Using a Collet System in Thread Cutting

Advantages over traditional chuck systems. Improved accuracy and repeatability in threading operations.Using a collet system for thread cutting offers big perks! Unlike traditional chuck systems, collets hold your workpiece snugly. This means *better accuracy* and *repeatability*. Picture this: no more wobbly threads! With a collet, you’ll get consistent results every time. Plus, they’re super easy to change, saving you time. In a world where seconds count, who wouldn’t want that?

| Feature | Collet System | Chuck System |

|---|---|---|

| Accuracy | High | Medium |

| Repeatability | Excellent | Good |

| Ease of Use | Simple | Can be tricky |

Setting Up a Collet System for Thread Cutting

Stepbystep guide to installation and alignment. Common setup mistakes to avoid.Installing a collet system for thread cutting involves a few simple steps. First, clean the lathe and parts carefully. Next, attach the collet to the spindle and tighten it securely. Make sure it’s correctly aligned with the lathe. Check the tightening mechanism to avoid slippage during use. Here are common mistakes to avoid:

- Not cleaning parts properly.

- Improper alignment of the collet.

- Over-tightening which can damage components.

Pay attention to these details, and your setup will be smoother and safer!

How do I align the collet system properly?

Align the collet by checking the gap between the collet and the workpiece. A small space should exist. Use a dial indicator for accuracy.

Maintenance and Care for Lathe Collet Systems

Best practices for cleaning and lubricating collets. Tips for extending the lifespan of your collet system.To keep your lathe collet system happy, cleaning and lubrication are key. Use a soft cloth to wipe away dust and grime from the collets. For lubrication, a few drops of machine oil do the trick; think of it as a spa day for your tools! Clean and well-oiled collets last longer, giving you smooth thread cutting. Storing them in a dry place also helps prevent rust. Remember, a rusty collet is like a soggy sandwich—no one wants that!

| Maintenance Tips | Benefits |

|---|---|

| Regular cleaning | Prevents dirt buildup. |

| Proper lubrication | Enhances performance. |

| Dry storage | Reduces rust risk. |

Common Troubleshooting Issues and Solutions

Identification of common problems during thread cutting. Practical solutions to address and resolve issues.Thread cutting can cause a few problems. Knowing what to look for helps fix them quickly. Here are some common issues:

- Chatter or vibration noises.

- Inconsistent thread depth.

- Tool wear or breakage.

To solve these problems, try these tips:

- Check the tool and adjust its position.

- Use a slower speed for cutting.

- Regularly lubricate your machine.

Finding and fixing these issues early can improve your work quality.

What are common issues in thread cutting?

Some common issues include vibrations, uneven thread depth, and tool damage. These problems can lower the quality of your work.

Choosing the Right Collet System for Your Metal Lathe

Factors to consider: size, type, and threading requirements. Recommendations for top brands and models in the market.Choosing the right collet system for your metal lathe matters a lot. Consider these key factors:

- Size: Make sure the collet fits your lathe’s spindle size.

- Type: Different types work better for various projects. Pick one that suits your needs.

- Threading Requirements: Ensure the collet matches your threading tasks.

Some top brands are:

- Rohm

- Schunk

- Glacern

These brands offer reliable options for quality collet systems. Choose wisely for the best results!

What are collet systems used for?

Collet systems are used to hold workpieces in place during machining tasks. They ensure precision and accuracy while cutting threads and shaping metal.

Real-world Applications of Collet Systems in Thread Cutting

Case studies of industries that benefit from using collet systems. Examples of projects where precision threading is crucial.Collet systems are like superheroes in the world of thread cutting. They help many industries make precise parts that fit together perfectly. For example, in the automotive sector, collets are used for crafting small yet vital pieces in engines. A tiny mistake can lead to big trouble, so precision is key! In aerospace, parts must fit together snugly—like a puzzle but without the missing pieces. Check out the table below for more examples:

| Industry | Project Example | Importance of Precision |

|---|---|---|

| Automotive | Engine components | Small mistakes can cause big problems! |

| Aerospace | Aircraft parts | Fit is crucial for safety! |

| Medical | Surgical tools | Error is not an option! |

These examples show why collet systems are essential for making sure everything works smoothly. Think of them as the glue that holds important machines together!

Conclusion

In summary, a lathe collet system helps hold metal pieces securely while you thread cut. This tool is essential for precision and accuracy. Remember to choose the right collet for your project. If you want to learn more, check out tutorials or practice with simple projects. Getting comfortable with this system will boost your metalworking skills and confidence!FAQs

Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Thread Cutting On Metal Lathes:Sure! A lathe is a machine that helps you shape metal. A collet system holds the metal piece tightly so it doesn’t move. This lets us cut threads, which are like little ridges on screws. When we cut threads, we make them fit perfectly with nuts. Using a lathe and collet helps us make strong, neat parts.

Sure! Please provide the question you would like me to answer.

What Are The Advantages Of Using A Collet System Over Traditional Chuck Systems For Holding Workpieces On A Metal Lathe During Thread Cutting?Using a collet system to hold workpieces on a metal lathe has many benefits. First, collets grip tighter and more evenly. This means your workpiece stays safer while you cut. Second, it’s easier to change the workpiece quickly. Finally, collets can hold small items better than traditional chucks. This helps you make more precise shapes when cutting threads.

How Do Different Types Of Collets (E.G., Er Collets, Sherline Collets) Affect The Precision And Versatility Of Threading Operations On A Lathe?Collets are tools that hold the metal pieces on a lathe. Different collets, like ER collets and Sherline collets, help with accuracy. ER collets grip tightly, making precise threads. Sherline collets are smaller and great for detailed work. Choosing the right collet makes your projects easier and better!

What Are The Key Steps Involved In Setting Up A Lathe For Thread Cutting Using A Collet System, And How Do You Ensure Proper Alignment And Tension?To set up a lathe for thread cutting with a collet system, first, you need to gather your tools and materials. Next, securely attach the workpiece into the collet. Then, adjust the cutting tool to the right height and position it close to the workpiece. Check that everything is lined up straight, making small changes if needed. To ensure proper tension, tighten the collet firmly, but not too much to cause damage.

How Can You Adjust The Lathe’S Settings (Such As Spindle Speed And Feed Rate) For Optimal Performance When Cutting Threads Using Collets?To adjust the lathe for cutting threads with collets, start by setting the spindle speed. A slower speed usually works better for threading. Next, change the feed rate, which is how fast you move the tool. A slower feed rate helps make cleaner threads. Always check your work as you go, and adjust if needed!

What Troubleshooting Techniques Can Be Employed If The Threads Produced Using A Collet System On A Metal Lathe Exhibit Inaccuracies Or Defects?If the threads you make on a metal lathe using a collet system are not right, check a few things. First, make sure the collet is tightened properly. Next, look at the tool to see if it’s sharp and clean. You should also check if the lathe is set to the right speed and feed rate. Finally, try measuring your threads to see how they compare to what you want.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Thread Cutting On Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps you shape metal. A collet system holds the metal piece tightly so it doesn’t move. This lets us cut threads, which are like little ridges on screws. When we cut threads, we make them fit perfectly with nuts. Using a lathe and collet helps us make strong, neat parts.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over Traditional Chuck Systems For Holding Workpieces On A Metal Lathe During Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system to hold workpieces on a metal lathe has many benefits. First, collets grip tighter and more evenly. This means your workpiece stays safer while you cut. Second, it’s easier to change the workpiece quickly. Finally, collets can hold small items better than traditional chucks. This helps you make more precise shapes when cutting threads.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Collets (E.G., Er Collets, Sherline Collets) Affect The Precision And Versatility Of Threading Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Collets are tools that hold the metal pieces on a lathe. Different collets, like ER collets and Sherline collets, help with accuracy. ER collets grip tightly, making precise threads. Sherline collets are smaller and great for detailed work. Choosing the right collet makes your projects easier and better!”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Setting Up A Lathe For Thread Cutting Using A Collet System, And How Do You Ensure Proper Alignment And Tension?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a lathe for thread cutting with a collet system, first, you need to gather your tools and materials. Next, securely attach the workpiece into the collet. Then, adjust the cutting tool to the right height and position it close to the workpiece. Check that everything is lined up straight, making small changes if needed. To ensure proper tension, tighten the collet firmly, but not too much to cause damage.”}},{“@type”: “Question”,”name”: “How Can You Adjust The Lathe’S Settings (Such As Spindle Speed And Feed Rate) For Optimal Performance When Cutting Threads Using Collets?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the lathe for cutting threads with collets, start by setting the spindle speed. A slower speed usually works better for threading. Next, change the feed rate, which is how fast you move the tool. A slower feed rate helps make cleaner threads. Always check your work as you go, and adjust if needed!”}},{“@type”: “Question”,”name”: “What Troubleshooting Techniques Can Be Employed If The Threads Produced Using A Collet System On A Metal Lathe Exhibit Inaccuracies Or Defects?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the threads you make on a metal lathe using a collet system are not right, check a few things. First, make sure the collet is tightened properly. Next, look at the tool to see if it’s sharp and clean. You should also check if the lathe is set to the right speed and feed rate. Finally, try measuring your threads to see how they compare to what you want.”}}]}