Have you ever watched a lathe at work? It’s fascinating how a block of wood or metal can turn into a beautiful item. But did you know that a lathe compound angle chart can make this process even easier? This chart helps you find the right angles for your projects. Imagine building something amazing without guessing angles. Wouldn’t that save you time?

When you use a lathe, getting the angles right is crucial. A small mistake can change everything! It surprises many to learn how important these angles are in shaping materials. With a lathe compound angle chart, things get much clearer. You won’t just work harder; you’ll work smarter.

In this article, we’ll explore how a lathe compound angle chart works. We’ll share tips and tricks to help you master your projects. So let’s dive in and discover the secrets of making perfect angles!

Essential Lathe Compound Angle Chart For Precision Machining

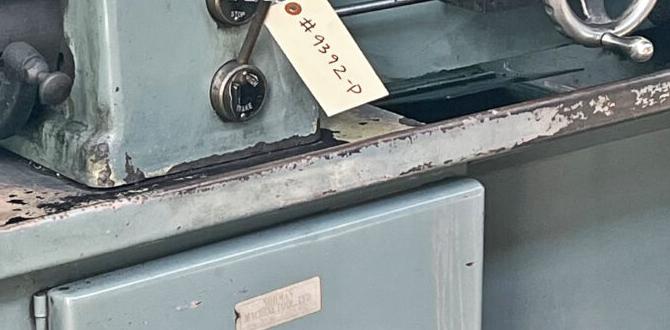

Lathe Compound Angle Chart

Understanding the lathe compound angle chart can seem tricky, but it’s essential for accurate machining. This chart helps machinists determine the angles needed for cutting and shaping materials. Knowing these angles ensures precise work, leading to better product outcomes. Imagine you’re creating a wooden toy; using the right angles will make it fit perfectly. A fun fact: even small mistakes in angles can lead to big issues in your final project. So, mastering this chart is key!Components of the Lathe Compound Angle Chart

Explanation of the key elements featured in the chart. Relationship between angles, tools, and workpieces.The lathe compound angle chart is like a treasure map for machinists. It shows key elements like angles, tools, and workpieces. Each angle aligns perfectly with a tool’s position, allowing for precise cuts. Understanding this relationship is crucial—think of it like matching socks!

| Angle Type | Associated Tool | Workpiece Position |

|---|---|---|

| Compound Angle | Cutting Tool | Workpiece at an angle |

| Inclined Angle | Tool Rest | Flat workpiece |

Each element plays a fun role in making a great product. So, understanding these components makes the job smoother, like butter on a hot pancake!

How to Read a Lathe Compound Angle Chart

Stepbystep guide on interpreting the chart accurately. Common pitfalls to avoid when using the chart.Reading a lathe compound angle chart can be easy if you follow a few steps. First, identify the angle you need. Then, match it with the right values on the chart. Check if the chart has degrees or radians labeled. Be careful! A common mistake is to overlook these labels. They help you choose the correct settings.

To avoid errors, keep these points in mind:

- Always double-check the angles.

- Ensure your tool is properly aligned.

- Consult additional guides if unsure.

How do you use a lathe compound angle chart?

To use it, find your desired angle, read the values, and adjust your lathe settings accordingly.

Taking your time and being careful can help you read the chart perfectly. Happy crafting!

Applications of the Lathe Compound Angle Chart

Examples of projects utilizing the chart for precision machining. Benefits of using the chart in various lathe operations.Projects using a lathe compound angle chart can include everything from making custom knife handles to crafting intricate clock gears. By following this chart, machinists achieve lovely, precise angles. Benefits include better accuracy, faster work, and fewer mistakes—like not accidentally turning a square into a pancake! The chart makes complex cuts easier, helping everyone from hobbyists to pros create amazing parts. Plus, it feels great to show off perfectly angled pieces!

| Project Example | Benefit |

|---|---|

| Custom Knife Handles | Enhanced Precision |

| Intricate Clock Gears | Reduced Errors |

| Machine Parts | Faster Production |

Best Practices for Using the Lathe Compound Angle Chart

Tips for achieving optimal results with the chart. Recommended tools and setups for effective angle calculations.To get the best results with the lathe compound angle chart, follow these tips. Always double-check your angles before cutting. Use accurate measuring tools like a protractor or digital angle finder. This helps in hitting the right measurements. Consistency is key. Make sure your lathe setup is stable and properly aligned for better results.

Here are some recommended tools:

- Protractor

- Digital angle finder

- Caliper

- Tape measure

Keep your workspace tidy. A clean area leads to fewer mistakes. Remember to practice and take your time. Learning the angles can be fun!

What is the best tool to use with a lathe compound angle chart?

A protractor or digital angle finder works best for accurate angle measurement when using a lathe compound angle chart.

Common Mistakes When Using a Compound Angle Chart

Identification of frequent errors made by machinists. Solutions to rectify these mistakes for better results.Many machinists stumble when reading a compound angle chart. One common mistake is miscalculating angles. This can lead to wonky cuts and a lot of wasted materials—yikes! Another error is ignoring the chart’s instructions altogether. Always follow the directions, or you might find yourself creating… well, something that looks more like modern art than a machine part! To fix these errors, double-check your calculations and use a protractor. Remember, practice makes perfect, but no one wants a “masterpiece” that’s out of whack!

| Mistake | Solution |

|---|---|

| Misreading angles | Double-check with a protractor |

| Ignoring instructions | Follow the chart step by step |

| Not practicing | Do a few test cuts first |

Advanced Techniques Integrating the Lathe Compound Angle Chart

Discussion on integrating the chart with CNC lathes for precision. Exploring advanced calculations and setups for complex projects.Using the lathe compound angle chart with CNC lathes boosts precision in machining. It helps to calculate the right angles for complex cuts. This means fewer mistakes and better results. Advanced setups can include:

- Understanding tool paths

- Adjusting the spindle speed

- Accurate positioning for each cut

With these techniques, you can tackle challenging projects with confidence. The right calculations lead to perfect pieces, every time.

How can I use the lathe compound angle chart for CNC machining?

You can use the chart to set accurate angles for cuts, making the process smoother and reducing errors. This makes your projects easier and your results better!

Conclusion

In summary, a lathe compound angle chart helps you cut accurate angles when using a lathe. It shows you how to adjust the tool rest and the table for different angles. Understanding this chart makes your work easier and more precise. We encourage you to practice using the chart and explore more about lathe techniques for better projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Compound Angle Charts:A lathe compound angle chart helps you understand how to cut shapes on a lathe machine. You can find the angles you need to set your tools. This makes it easier for you to create parts that fit together. You can use these charts for different projects, like making toys or other things. Learning how to read them will make you a better maker!

Sure! Please provide the question you’d like me to answer.

What Is A Compound Angle Chart Used For In Lathe Machining, And How Does It Improve Precision In Cutting Operations?A compound angle chart helps you find the right angles to cut on a lathe machine. It shows different angles you need for different shapes. Using this chart helps us cut more accurately. This means your pieces will fit together better and look nicer. It makes your work easier and more precise!

How Do You Interpret The Values Provided In A Lathe Compound Angle Chart For Setting Up The Toolpost?To use a lathe compound angle chart, you first find the angle you need. Each number tells you how to tilt the toolpost. We look at the chart together, then adjust the tool to match the angles. This helps us make accurate cuts on the metal. Always double-check your settings before starting!

What Factors Should Be Considered When Using A Compound Angle Chart To Determine The Angles For Cutting A Specific Workpiece Profile?When using a compound angle chart, you should think about the shape you want to cut. Check the sizes and marks on the chart. Make sure your tools can handle the angles shown. Also, consider the type of material you’re cutting, like wood or metal. These factors help you get the angles just right!

How Do You Calculate The Necessary Compound Angles For Complex Cuts When The Compound Angle Chart Does Not Provide Direct Values?To calculate compound angles for cuts without direct values, you can break the problem into smaller parts. First, look at the angles you already know. Then, use basic math to find missing parts. You can also draw a picture to help you see the angles better. Finally, double-check your work to make sure it looks right!

Can You Provide Examples Of Common Applications Where A Lathe Compound Angle Chart Is Essential For Achieving Accurate Results, And How It Would Be Applied In Those Scenarios?A lathe compound angle chart helps us when we need to cut special shapes. For example, if you’re making a part for a toy car, you might need to cut at a specific angle. We use the chart to find the right angles to set our machine. If we get the angles wrong, the parts won’t fit together. So, the chart is very important for making sure everything works perfectly!