Have you ever wondered how precise tools help in making wonderful things? A lathe is one of those amazing tools. Its compound rest helps keep everything in line. But there’s something more important than just the tool itself: scale accuracy. Without perfect measurements, even the best lathe can make mistakes.

Imagine you are building a model car. If your cuts are not accurate, it might not fit together properly. This can happen if the scale on a lathe isn’t set right. In this article, we will explore lathe compound rest scale accuracy. We’ll look into why it matters and how it can make or break your projects.

Believe it or not, many makers find that even a tiny error can change the whole outcome. Just picture your project turning out crooked. It’s frustrating, right? Knowing how to check and improve scale accuracy can save the day. Let’s dive in and discover how to get the most for your lathe!

Lathe Compound Rest Scale Accuracy: Enhancing Precision

Lathe Compound Rest Scale Accuracy

Lathe compound rest scale accuracy is key for precise machining. A well-calibrated scale helps you make exact adjustments, ensuring smoother cuts. Have you ever wondered how a tiny miscalibration can ruin a whole project? Even minor errors can lead to disappointing results. Proper setup and maintenance of the compound rest can boost your confidence and skill. Remember, accuracy makes all the difference between a masterpiece and a mistake! Keep your scales in tip-top shape for the best results.Understanding the Lathe Compound Rest

Definition and purpose of the compound rest. Key components of the compound rest.The compound rest is a key part of a lathe. It helps you position the cutting tool at different angles. This makes it easier to create precise shapes and cuts. Understanding its main features is important for good results. Here are the key components:

- Swivel Base: Allows tilting for angled cutting.

- Cross Slide: Moves the tool side to side.

- Tool Post: Holds the cutting tool securely.

With these parts, you can achieve great accuracy and efficiency while working on your projects.

What is the purpose of the compound rest?

The compound rest lets you adjust the tool’s position for angled cuts. It improves lathe compound rest scale accuracy for better craftsmanship.

What are its key components?

The main parts include a swivel base, cross slide, and tool post, which help in positioning the cutting tool correctly.

Importance of Scale Accuracy in Machining

Impact of scale accuracy on machining precision. Common issues arising from scale inaccuracies.Scale accuracy is very important in machining. It affects how well machines cut and shape materials. High precision is a must for good results. If the scale is off, it can lead to mistakes. Here are some common problems from inaccurate scales:

- Improper dimensions

- Poor surface finish

- Increased waste of materials

- Longer production time

Staying aware of these issues helps ensure better quality in machining work. Good scale accuracy means fewer problems and happier customers!

Why is scale accuracy important in machining?

Scale accuracy ensures the right measurements, leading to better fits and finishes. If measurements are wrong, it can ruin the final product.

Factors Affecting Scale Accuracy

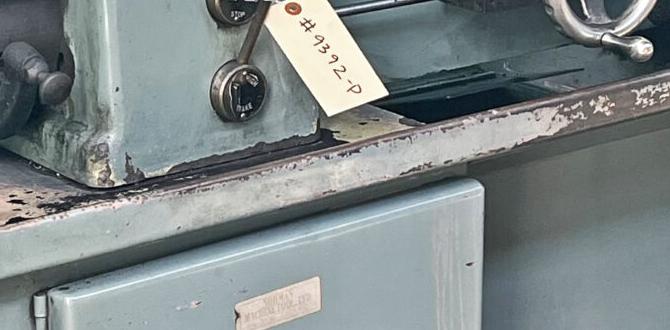

Wear and tear of the scale components. Environmental factors influencing accuracy.Many things can mess with scale accuracy. First, wear and tear of scale parts can create small errors. If the components are old or damaged, they just might not measure correctly. That’s like trying to read a map with blurry glasses!

Next, let’s talk about the environment. Dust, temperature changes, and even humidity can affect how well the scale works. Imagine baking cookies in the rain—your results might not be tasty, right? Keeping these factors in check can help make sure your lathe does its job properly.

| Factor | Effect on Accuracy |

|---|---|

| Wear and Tear | Causes measurement errors |

| Dust | Interferes with movement |

| Temperature Changes | Can cause parts to expand or contract |

| Humidity | Affects scale readings |

Calibration Techniques for Lathe Compound Rest

Stepbystep calibration process. Tools required for accurate calibration.To ensure your lathe compound rest works well, you need to calibrate it correctly. Here’s a simple step-by-step guide:

- Gather the tools: a level, a caliper, a ruler, and a wrench.

- Check the base: Place the level on the lathe bed. Adjust until it’s level.

- Align the compound rest: Use the caliper to measure. Make adjustments as needed.

- Test the movements: Slide the rest side to side and up and down. It should move smoothly.

Following these steps helps keep your lathe accurate and efficient.

What tools do I need for calibration?

You need a level, caliper, ruler, and wrench. These tools make calibration easier and ensure accuracy.

Adjusting Compound Rest for Enhanced Precision

Methods for adjusting the compound rest. Tips for maintaining stability during adjustments.To adjust the compound rest for better accuracy, you can start by loosening the lock knobs carefully. This lets you slide it to the desired angle without snapping it like a twig! Then, proactively check the scales to ensure everything lines up nicely. It’s like reading a treasure map, where each mark helps you find gold!

For stability during adjustments, try holding the rest firmly with one hand while tweaking with the other. Don’t be that person who accidentally moves the whole lathe while adjusting! Remember, a little bit of patience can go a long way in achieving perfect alignment, and who wouldn’t want their work to be spot on?

| Method | Tips |

|---|---|

| Loosen Lock Knobs | Use one hand to hold the rest steady. |

| Check Scales | Align everything carefully. |

| Adjust Slowly | Patience is key! |

Regular Maintenance for Sustaining Accuracy

Routine checks for scale integrity. Recommended maintenance schedule.Keeping your lathe compound rest scale in check is not just smart; it’s essential! Regularly checking for scale integrity helps catch small problems before they grow. Inspect the scale for dirt and damage. Clean it gently to avoid scratches. Follow this easy schedule for maintenance:

- Daily: Clean the scale and check for visible damage.

- Weekly: Calibrate the scale for precise readings.

- Monthly: Inspect all components for wear.

Sticking to this routine helps ensure your lathe works well and stays accurate.

How do I check scale integrity?

To check the scale’s integrity, visually inspect it for scratches or dirt. Use a soft cloth to clean any grime. Always ensure it moves smoothly without sticking to maintain accuracy.

Advanced Techniques for Expert Lathe Operators

Techniques to finetune scale accuracy. Leveraging technology for enhanced precision.Expert lathe operators can improve scale accuracy with a few advanced techniques. First, use high-quality measuring tools. This ensures that readings are precise. Second, consider software solutions. They can provide real-time accuracy checks. Third, regular maintenance of your lathe is crucial. It keeps everything in top shape. Lastly, engage in constant learning. Staying updated helps refine your skills.

How can I improve scale accuracy on a lathe?

You can improve scale accuracy by using precise measuring tools and software solutions for real-time adjustments. Regular maintenance and continuous learning are also key to enhancing your skills.

- Use precise measuring equipment.

- Leverage software solutions for accuracy.

- Maintain your lathe regularly.

- Commit to continuous skill improvement.

Real-World Applications and Case Studies

Examples of improved machining outcomes through accuracy. Testimonials from experienced machinists.Accuracy in machining leads to better results. Many machinists have shared stories of their success. They say using precise tools makes a big difference. For example, when a lathe compound rest is accurately set, it can reduce waste and save time. Here are some key points:

- Improved fit and finish of parts.

- Less material wasted during production.

- Higher customer satisfaction due to quality work.

Testimonials show that accuracy matters. One machinist said, “My lathe’s precision helped me win jobs.” This proves that taking care of details pays off.

How does accuracy in machining help?

Accuracy ensures parts fit together well. It reduces mistakes, saves money, and keeps customers happy.

Conclusion

In summary, lathe compound rest scale accuracy is crucial for precise machining. Always check your scale before starting projects to avoid mistakes. You can improve accuracy by regularly calibrating your equipment. Explore more about lathe setups and techniques to enhance your skills. Remember, practice makes you better. So, keep learning and experimenting with every project you undertake!FAQs

How Can I Ensure The Accuracy Of The Compound Rest Scale On My Lathe For Precise Machining Operations?To make sure the compound rest scale on your lathe is accurate, first check the scale using a ruler or caliper. You can also adjust it if it’s not lined up right. Make sure the lathe is level on a flat surface. Finally, test it by making a few small cuts and see if the measurements match. This way, you can be sure you are getting precise results!

What Are Common Sources Of Error That Can Affect The Accuracy Of The Compound Rest Scale In Lathe Setups?Common sources of error with the compound rest scale on a lathe include not zeroing it correctly. If you start with the wrong reading, your cuts will be off. Dirt or debris on the scale can also cause mistakes. Sometimes, the scale might be loose or not lined up right. Finally, using the wrong tools can lead to errors too.

How Often Should I Calibrate The Compound Rest Scale To Maintain Machining Precision?You should check and calibrate the compound rest scale every month or before starting a big project. This helps keep your machine accurate and your work precise. If you notice anything off, fix it right away. Regular checks make sure your projects turn out great!

What Techniques Can Be Used To Align The Compound Rest With The Lathe Bed To Improve Scale Accuracy?To align the compound rest with the lathe bed, you can use a few simple methods. First, check if the rest is level using a small level tool. Next, adjust the screws under the rest until it is straight. You can also measure distances on both sides to make sure they match. This way, you will help the lathe cut accurately!

Are There Specific Types Of Lathe Compound Rest Scales That Are Known For Higher Accuracy, And What Features Should I Look For?Yes, some lathe compound rest scales are more accurate than others. Look for scales made of high-quality materials. You want clear markings that are easy to read. Also, choose scales that have a fine adjustment feature. This helps you make small, precise changes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “How Can I Ensure The Accuracy Of The Compound Rest Scale On My Lathe For Precise Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the compound rest scale on your lathe is accurate, first check the scale using a ruler or caliper. You can also adjust it if it’s not lined up right. Make sure the lathe is level on a flat surface. Finally, test it by making a few small cuts and see if the measurements match. This way, you can be sure you are getting precise results!”}},{“@type”: “Question”,”name”: “What Are Common Sources Of Error That Can Affect The Accuracy Of The Compound Rest Scale In Lathe Setups? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common sources of error with the compound rest scale on a lathe include not zeroing it correctly. If you start with the wrong reading, your cuts will be off. Dirt or debris on the scale can also cause mistakes. Sometimes, the scale might be loose or not lined up right. Finally, using the wrong tools can lead to errors too.”}},{“@type”: “Question”,”name”: “How Often Should I Calibrate The Compound Rest Scale To Maintain Machining Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check and calibrate the compound rest scale every month or before starting a big project. This helps keep your machine accurate and your work precise. If you notice anything off, fix it right away. Regular checks make sure your projects turn out great!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Align The Compound Rest With The Lathe Bed To Improve Scale Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the compound rest with the lathe bed, you can use a few simple methods. First, check if the rest is level using a small level tool. Next, adjust the screws under the rest until it is straight. You can also measure distances on both sides to make sure they match. This way, you will help the lathe cut accurately!”}},{“@type”: “Question”,”name”: “Are There Specific Types Of Lathe Compound Rest Scales That Are Known For Higher Accuracy, And What Features Should I Look For? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some lathe compound rest scales are more accurate than others. Look for scales made of high-quality materials. You want clear markings that are easy to read. Also, choose scales that have a fine adjustment feature. This helps you make small, precise changes.”}}]}