Have you ever wondered how a simple piece of metal can be turned into a masterpiece? Metalworking is like magic. You start with raw material, and with the right tools, you create something amazing. One important tool in metalworking is the lathe. It makes shaping metal easy and precise.

But did you know you can make your metal lathe even better? That’s where the lathe conversion comes in. A lathe conversion can improve your machine’s abilities. It allows you to use a compound rest, which helps you make more complex shapes. Imagine turning a plain piece of metal into a beautiful part for a project. That’s the power of a well-equipped lathe!

In this article, we will explore how to convert your lathe and add a compound rest. You’ll discover the benefits, tips, and tricks to make it work for you. Get ready to unlock new possibilities in your metalworking journey!

Lathe Conversion: Upgrading Your Metal Lathe Compound Rest

Lathe Conversion: Metal Lathe Compound Rest

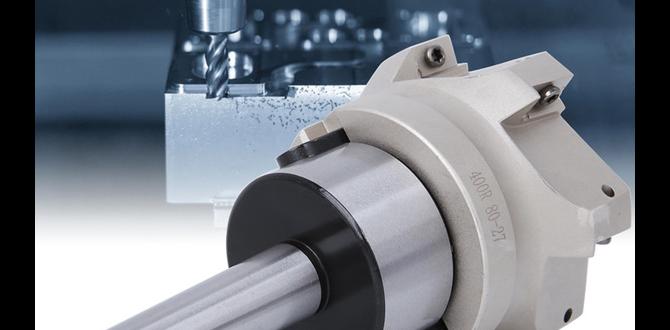

Converting a standard lathe into a metal lathe with a compound rest can transform your metalworking experience. Imagine having precise control while shaping metal! A compound rest allows you to tilt and turn your workpiece smoothly. This feature boosts accuracy when cutting threads or making intricate designs. Did you know that upgrading can be a DIY project? Many hobbyists find great satisfaction in crafting their own tools. Embrace this exciting improvement and discover the difference it makes in your projects!Understanding Lathe Conversions

Definition of lathe conversion. Importance of lathe modifications for enhancing performance.A lathe conversion means changing a basic lathe into a more advanced tool. It improves how the lathe works and can make your projects smoother and faster. Think of it like giving your bike new wheels to zoom around! With upgrades, you can create better shapes and designs. This makes your work more fun and your results stunning. Every tweak counts towards a masterpiece. So, let’s rev up those lathes and turn some wood or metal with style!

| Lathe Conversion Benefit | Explanation |

|---|---|

| Increased Precision | Small adjustments help your lathe cut better. |

| Faster Setup | Modifications make changing tools quicker! |

| Enhanced Versatility | More options mean more fun and creativity. |

Benefits of Upgrading Your Compound Rest

Improved accuracy and precision. Enhanced usability for various projects.Upgrading your compound rest can give you superpowers! Well, maybe not exactly superpowers, but definitely better accuracy and precision. With a new compound rest, you’ll notice smoother movements and tighter cuts. Projects that used to take forever now become a walk in the park, making you feel like a woodworking wizard. Plus, with improved functionality, your lathe can handle all sorts of projects, from tiny trinkets to big masterpieces. Just think: fewer mistakes mean more time for snacks!

| Benefit | Description |

|---|---|

| Improved Accuracy | Smoother adjustments lead to precise cuts. |

| Enhanced Usability | Handles a variety of projects easily. |

Selecting the Right Compound Rest for Your Lathe

Factors to consider: size, compatibility, and material. Popular brands and models in the market.Choosing the right compound rest can feel like finding a needle in a haystack. First, check the size. It needs to fit your lathe snugly, like a glove. Next, think about compatibility. Not all rests play nice with every lathe. Lastly, consider the material. Aluminum might be lightweight, but cast iron is like the heavyweight champion of durability! Popular brands like Grizzly and Jet offer solid options. You wouldn’t want a wobbly compound rest making your projects look like modern art, right?

| Brand | Material | Size Compatibility |

|---|---|---|

| Grizzly | Cast Iron | 14” – 18” Lathes |

| Jet | Aluminum | 10” – 12” Lathes |

| Shop Fox | Steel | 12” – 14” Lathes |

Tools and Materials Needed for Conversion

Essential tools for lathe conversion projects. Recommended materials for building or upgrading compound rests.Thinking about a lathe conversion? First, grab some essential tools! You’ll need a wrench, a drill, and a good set of screwdrivers. Don’t forget your safety glasses—your eyes will thank you! For upgrading that compound rest, materials like aluminum, steel, or even sturdy plastics work wonders. Choose wisely, and you’ll have a machine that’s as smooth as butter. Ready to dive in? Let’s make that lathe sing!

| Tools | Recommended Materials |

|---|---|

| Wrench | Aluminum |

| Drill | Steel |

| Screwdrivers | Sturdy Plastics |

| Safety Glasses |

Step-by-Step Guide to Converting Your Compound Rest

Preparing your lathe and workspace. Detailed instructions for disassembly and installation.Before diving into the exciting world of lathe conversion, make sure your workspace is clean and well-lit. A tidy area helps prevent accidents. Gather all your tools, like wrenches and screwdrivers, and maybe grab a snack. You’ll need energy for this adventure! Next, carefully disassemble your lathe. Remember, every bolt you remove should find its way back, like a lost puppy. Label parts if needed, so they don’t play hide-and-seek later. Once everything is out, follow these steps for a smooth installation:

| Step | Action |

|---|---|

| 1 | Clean all parts to avoid dust bunnies. |

| 2 | Install the new compound rest securely. |

| 3 | Tighten bolts to keep it steady. |

| 4 | Reconnect the power source and test it out! |

With patience and a little elbow grease, you’ll have a newly converted compound rest that may just wiggle and jiggle with joy. Happy lathe-ing!

Common Challenges and Troubleshooting Tips

Frequent issues encountered during conversion. Solutions and tips to make the process smoother.Working with a lathe conversion can be tricky. Common issues might pop up like misalignment, noise, or vibrations. These annoyances can be fixed! Here are some tips:

- Check for loose parts and tighten them.

- Adjust the alignment of the tool rest carefully.

- Make sure the lathe is on a steady surface.

- Lubricate moving parts to reduce noise.

These solutions can help make your project smoother and more fun!

What are common problems with lathe conversion?

Often, users face misalignment or vibrations. Misalignment can result in uneven cuts. Proper adjustments can make a big difference!

Maintaining Your Upgraded Compound Rest

Best practices for care and maintenance. Signs that indicate a need for further adjustments or repairs.Taking care of your upgraded compound rest keeps it working well. Regular cleaning is important. Wipe it down after each use to remove dust and metal shavings. Inspect for any loose screws or parts. Lubricate moving parts to avoid rust. If you notice strange noises during use or if the tool feels stiff, these are signs of trouble. Address them right away to avoid bigger issues.

What are the signs that indicate a need for adjustments?

The signs include:

- Noisy operation

- Difficulty moving parts

- Inaccurate cuts

If you see these signs, make adjustments quickly.

Real-Life Applications of Upgraded Compound Rests

Examples of projects that benefit from improved compound rests. Case studies or testimonials from experienced users.Upgraded compound rests open up a world of fun projects! Imagine making a cool wooden toy or a precise metal part for a robot. One user, after swapping their old compound rest, said they cut down project time by half. They were amazed! Another happy maker crafted a beautiful vase with perfect angles. Upgrades make it easier to do finer work. Check out some examples below:

| Project | User Benefit |

|---|---|

| Wooden Toy | Faster cutting |

| Metal Part | Better precision |

| Vase | Perfect angles |

Resources for Further Learning

Recommended books, websites, and online forums. Video tutorials and workshops for handson learning.If you want to dive deeper into the world of lathes, check out some great resources! Books can be your best friends here. Don’t forget to explore popular websites and online forums for tips and tricks. For hands-on learners, video tutorials and workshops are pure gold. They can turn you into a lathe wizard faster than you can say “metal shavings.” Here’s a table to get you started:

| Type | Resource |

|---|---|

| Books | Machinery’s Handbook, Lathework: A Complete Guide |

| Websites | LINDELLS.com, FLYNN’S Lathe Tutorials |

| Online Forums | practicalmachinist.com, latheforum.com |

| Video Tutorials | YouTube Channels like “This Old Tony” |

| Workshops | Local Community Colleges, Maker Spaces |

These resources will turn your lathe dreams into reality. Get ready to cut, shape, and create like a pro!

Conclusion

In conclusion, a lathe conversion for a metal lathe compound rest can enhance your machining experience. It improves accuracy and efficiency while allowing for creative projects. You can easily upgrade your tools to achieve better results. If you’re interested, consider researching more about lathe conversions and their benefits. Start exploring today to elevate your metalworking skills!FAQs

What Are The Key Differences Between A Traditional Compound Rest And A Converted Compound Rest On A Metal Lathe?A traditional compound rest lets you move the cutting tool in two directions: side to side and up and down. A converted compound rest might have extra features or be changed to work better with different tools. This can make it easier to do special projects. Traditional rests are often simpler, while converted ones can be more versatile. Both help us cut metal shapes, but they do it in slightly different ways.

What Tools And Materials Are Typically Required For Converting A Standard Lathe’S Compound Rest?To convert a standard lathe’s compound rest, you usually need a few tools and materials. First, have a wrench for removing parts. You’ll also need screws and nuts for reassembly. A measuring tool helps ensure everything fits well. Lastly, you might need some metal pieces, depending on your specific project.

How Does The Design Of A Converted Compound Rest Improve Precision And Usability In Metalworking?A converted compound rest helps you move your tools more easily and exactly. Its design makes it simple to adjust angles while working. This means you can cut metal more accurately. You get better control, which makes your projects turn out nicer. Using it can help you feel more confident and skilled in metalworking.

What Common Challenges Might A Machinist Face When Converting A Compound Rest On A Metal Lathe?When you convert a compound rest on a metal lathe, you might face a few challenges. First, it can be tricky to get the measurements right. If the settings aren’t accurate, the workpiece may not come out properly. Also, you may need special tools, and finding them can be hard. Finally, making sure everything fits together smoothly takes practice and patience.

Can You Provide Step-By-Step Instructions For Converting A Compound Rest On A Manual Metal Lathe?Sure! Here’s how to convert a compound rest on a manual metal lathe: 1. First, turn off the lathe and unplug it. Safety is important! 2. Next, find the locking screws on the compound rest. Loosen them with a wrench. 3. Carefully lift the compound rest off the slide. Be gentle! 4. Now, place the new or adjusted compound rest on the slide. 5. Tighten the locking screws until they hold it firmly. You’re all set to start using your lathe!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Differences Between A Traditional Compound Rest And A Converted Compound Rest On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A traditional compound rest lets you move the cutting tool in two directions: side to side and up and down. A converted compound rest might have extra features or be changed to work better with different tools. This can make it easier to do special projects. Traditional rests are often simpler, while converted ones can be more versatile. Both help us cut metal shapes, but they do it in slightly different ways.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Typically Required For Converting A Standard Lathe’S Compound Rest? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To convert a standard lathe’s compound rest, you usually need a few tools and materials. First, have a wrench for removing parts. You’ll also need screws and nuts for reassembly. A measuring tool helps ensure everything fits well. Lastly, you might need some metal pieces, depending on your specific project.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Converted Compound Rest Improve Precision And Usability In Metalworking? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A converted compound rest helps you move your tools more easily and exactly. Its design makes it simple to adjust angles while working. This means you can cut metal more accurately. You get better control, which makes your projects turn out nicer. Using it can help you feel more confident and skilled in metalworking.”}},{“@type”: “Question”,”name”: “What Common Challenges Might A Machinist Face When Converting A Compound Rest On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you convert a compound rest on a metal lathe, you might face a few challenges. First, it can be tricky to get the measurements right. If the settings aren’t accurate, the workpiece may not come out properly. Also, you may need special tools, and finding them can be hard. Finally, making sure everything fits together smoothly takes practice and patience.”}},{“@type”: “Question”,”name”: “Can You Provide Step-By-Step Instructions For Converting A Compound Rest On A Manual Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s how to convert a compound rest on a manual metal lathe: 1. First, turn off the lathe and unplug it. Safety is important! 2. Next, find the locking screws on the compound rest. Loosen them with a wrench. 3. Carefully lift the compound rest off the slide. Be gentle! 4. Now, place the new or adjusted compound rest on the slide. 5. Tighten the locking screws until they hold it firmly. You’re all set to start using your lathe!”}}]}