Have you ever wondered how a simple machine can turn blocks of metal into precision parts? A lathe does just that. But not every lathe is the same. Many hobbyists and engineers want to upgrade their machines. That’s where the lathe conversion metal lathe drive system comes in.

Imagine transforming a basic lathe into a powerful tool. Why settle for less when you can enhance your project? By switching to a better drive system, you can improve accuracy and performance. It’s like giving your old bicycle a new engine!

Some people think converting a lathe is too complicated. But it can be fun and rewarding. Did you know that many metalworkers started their journey with just a little upgrade? Their stories show how a few changes can lead to great results.

In this article, we’ll explore how to convert your lathe. We’ll discuss the benefits and guide you through the process. You’ll see that the right drive system can make a huge difference in your work.

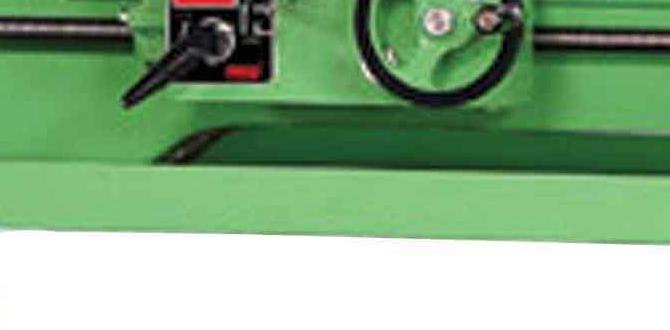

Lathe Conversion: Metal Lathe Drive System Explained

Lathe Conversion Metal Lathe Drive System

A lathe conversion metal lathe drive system changes how a lathe works. Imagine improving a bicycle by adding a powerful motor. Similarly, a drive system boosts performance, making metal shaping easier. This setup allows users to manage speed and torque more efficiently. Did you know that converting a manual lathe can save you time and effort? Understanding this system can lead to higher precision in metalwork, opening new creative doors.Understanding Lathe Conversions

Definition and purpose of lathe conversions. Benefits of converting a traditional metal lathe to a modern drive system.Lathe conversions involve upgrading traditional metal lathes to a more modern drive system. Why? Well, it’s like giving your old bicycle an electric motor! These upgrades improve performance and efficiency, making work faster and smoother. The benefits include greater precision and reduced noise. Plus, they can help save time, giving you more time for other fun projects—like finally finishing that treehouse you’ve always wanted!

| Benefits of Lathe Conversions | Description |

|---|---|

| Increased Efficiency | Work gets done faster with modern systems. |

| Improved Accuracy | Creates precise measurements for better results. |

| Less Noise | Enjoy a quieter workspace, perfect for thinking! |

Essential Components for a Successful Conversion

List of required components for conversion (motors, controllers, etc.). Recommended brands and models for reliability and performance.To make a metal lathe work smoothly, you need some important parts. Here’s a quick list of what you’ll need:

- Motor: A good quality motor is key. Brands like Baldor and Grizzly are reliable.

- Controller: Look for a controller from Precision Equipment or Chino. They help monitor speed and position.

- Power Supply: Choose a power supply that matches your motor’s needs for consistent power.

These parts play a big role in a successful conversion. You can trust these brands for great performance and reliability.

What are key components for lathe conversion?

Essential components include the motor, controller, and power supply. These parts ensure your lathe runs effectively and safely.

Step-by-Step Guide to Converting Your Metal Lathe

Detailed process of converting from a manual system to a drive system. Important adjustments to make for optimal performance.Converting your metal lathe to a drive system can feel like turning a bicycle into a jetpack! Start by carefully removing any old parts. Next, install the new drive motor and check that it fits snugly to avoid any funny movements. Adjustments are key! Make sure to properly align the belts and gears for a smooth ride. Lastly, take a moment to test everything. It should purr like a cat, not whir like a blender!

| Step | Description |

|---|---|

| 1 | Remove old components |

| 2 | Install new drive motor |

| 3 | Align belts and gears |

| 4 | Test for performance |

Common Challenges and Solutions

Typical issues encountered during conversion (alignment, noise, etc.). Troubleshooting tips and best practices.Every project can face problems. Common ones with lathe conversions include alignment issues and excessive noise. These can make your work more difficult. To fix these problems, consider these tips:

- Check alignment carefully. Make sure everything is straight.

- Keep parts clean to reduce noise.

- Lubricate moving parts regularly for smooth operation.

Following these best practices can help you achieve better results and a smoother experience.

What are typical issues faced during lathe conversion?

Common issues include misalignment of parts and increased noise levels. These can hinder performance and affect the quality of work.

Maintenance Tips for Converted Lathe Systems

Regular maintenance tasks to ensure longevity and performance. Signs that indicate maintenance is needed.Keeping your lathe system in good shape is key for long-lasting use. Simple tasks help achieve this. Here are some regular maintenance tips:

- Check for loose parts.

- Clean the machine after each use.

- Lubricate the moving parts regularly.

- Inspect the drive system and belts.

Watch for signs that maintenance is needed:

- Noisy operation.

- Vibrations during use.

- Difficulty in turning.

Taking care of your lathe ensures it works well and lasts longer. Wouldn’t you want your tools to perform their best?

How often should I maintain my lathe?

You should maintain your lathe every month for the best performance. Regular checks keep it running smoothly.

Real-Life Case Studies and Examples

Showcase of successful lathe conversions from various users. Lessons learned and insights from their experiences.Users across the globe have successfully converted their lathes, sharing some quirky tales along the way. One user turned an old lathe into a super-efficient machine that can even dance (watch out, Dancing with the Stars!). Their biggest lesson? Measure twice, cut once!. Another user transformed their basic setup and saw a 50% increase in productivity. Below is a look at their experiences:

| User | Conversion Detail | Lesson Learned |

|---|---|---|

| Sam | Old lathe to CNC | Don’t skip the manual! |

| Alice | Manual to automatic | Check your alignment! |

| Joe | DIY power feed | Have backup plans! |

These conversions show that with creativity and a little elbow grease, anything is possible—even if it means dancing with a lathe!

Resources and Further Reading

Recommended manuals, videos, and forums for additional learning. Links to online communities and support groups for metal lathe enthusiasts.If you’re ready to dive deeper into the world of metal lathes, there are some great resources waiting for you! Check out manuals like “Lathe Basics” for the fundamentals. For visual learners, YouTube has tons of helpful videos. Consult forums like “The Home Machinist” where friendly experts offer advice. It’s like having a chat with skilled buddies over coffee!

| Resource Type | Recommended Resource |

|---|---|

| Manuals | Lathe Basics |

| Videos | YouTube Channels (e.g., NYC CNC) |

| Forums | The Home Machinist |

| Communities | Facebook Groups for Metal Lathe Enthusiasts |

Don’t forget to explore online communities. Finding fellow metal lathe fans is like discovering a treasure chest of knowledge! So grab your favorite snack, buckle up, and get ready to learn!

Conclusion

In summary, a lathe conversion metal lathe drive system can upgrade your machine’s capabilities. You improve performance and precision by replacing old parts. It’s an exciting project that boosts your skills. Next, consider researching kits or guides online. You can find useful videos and tutorials to help you start. Let’s get started on your lathe journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Conversion Metal Lathe Drive Systems:Sure! Here are five questions about metal lathe drive systems. 1. What is a lathe? A lathe is a machine that spins metal or wood to shape it into something useful. 2. Why do we convert a lathe? We convert a lathe to make it work better or to use new technology. 3. How does a drive system help? A drive system helps the lathe turn and shape materials smoothly and accurately. 4. What parts are in a drive system? A drive system has motors, belts, and gears to control how fast things spin. 5. Can you make a lathe faster? Yes, you can make a lathe faster by changing its drive system or adding more power.

Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help.

What Are The Primary Differences Between A Traditional Belt Drive And A Direct Drive System In A Lathe Conversion?In a traditional belt drive, a belt connects the motor to the lathe. This means the motor spins the belt, which then turns the lathe. In a direct drive system, the motor connects straight to the lathe without a belt. This makes direct drive simpler and often gives you more power. However, belt drives can let you change speeds easily.

How Can One Determine The Optimal Motor Size And Type For A Lathe Conversion Project?To find the right motor for your lathe, start by checking the size of the lathe. You’ll need a motor that matches its weight and power needs. Next, think about what you will make with the lathe. If you plan to cut hard materials, you might need a bigger motor. Finally, read reviews or ask others for their advice on motor types that work best!

What Are The Advantages Of Using An Inverter Drive System For Controlling The Speed Of A Metal Lathe?Using an inverter drive system on a metal lathe helps us control the speed better. We can make the lathe go faster or slower easily. This makes our work smoother and more precise. It also saves energy, so we don’t waste electricity. Plus, it helps the lathe last longer by giving it a gentle start.

What Modifications Are Necessary To Retrofit An Existing Manual Lathe With A Modern Electronic Drive System?To retrofit a manual lathe with a modern electronic drive system, you need to make a few changes. First, you should remove the old motor and controls. Then, install a new electric motor that can change speeds easily. Next, add a control panel so you can manage the lathe more easily. Finally, connect everything with wires and test it to make sure it works well.

How Does The Choice Of Materials For Drive Components Impact The Overall Performance And Longevity Of A Converted Lathe System?Choosing the right materials for drive parts is very important. Strong materials help the machine work better and last longer. If you use weak parts, the machine might break or not work well. Good materials can handle more wear and tear, which means you won’t have to fix it often. This way, you enjoy using your lathe for a long time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Conversion Metal Lathe Drive Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about metal lathe drive systems. 1. What is a lathe? A lathe is a machine that spins metal or wood to shape it into something useful. 2. Why do we convert a lathe? We convert a lathe to make it work better or to use new technology. 3. How does a drive system help? A drive system helps the lathe turn and shape materials smoothly and accurately. 4. What parts are in a drive system? A drive system has motors, belts, and gears to control how fast things spin. 5. Can you make a lathe faster? Yes, you can make a lathe faster by changing its drive system or adding more power.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Primary Differences Between A Traditional Belt Drive And A Direct Drive System In A Lathe Conversion?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a traditional belt drive, a belt connects the motor to the lathe. This means the motor spins the belt, which then turns the lathe. In a direct drive system, the motor connects straight to the lathe without a belt. This makes direct drive simpler and often gives you more power. However, belt drives can let you change speeds easily.”}},{“@type”: “Question”,”name”: “How Can One Determine The Optimal Motor Size And Type For A Lathe Conversion Project?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right motor for your lathe, start by checking the size of the lathe. You’ll need a motor that matches its weight and power needs. Next, think about what you will make with the lathe. If you plan to cut hard materials, you might need a bigger motor. Finally, read reviews or ask others for their advice on motor types that work best!”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using An Inverter Drive System For Controlling The Speed Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using an inverter drive system on a metal lathe helps us control the speed better. We can make the lathe go faster or slower easily. This makes our work smoother and more precise. It also saves energy, so we don’t waste electricity. Plus, it helps the lathe last longer by giving it a gentle start.”}},{“@type”: “Question”,”name”: “What Modifications Are Necessary To Retrofit An Existing Manual Lathe With A Modern Electronic Drive System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To retrofit a manual lathe with a modern electronic drive system, you need to make a few changes. First, you should remove the old motor and controls. Then, install a new electric motor that can change speeds easily. Next, add a control panel so you can manage the lathe more easily. Finally, connect everything with wires and test it to make sure it works well.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Materials For Drive Components Impact The Overall Performance And Longevity Of A Converted Lathe System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right materials for drive parts is very important. Strong materials help the machine work better and last longer. If you use weak parts, the machine might break or not work well. Good materials can handle more wear and tear, which means you won’t have to fix it often. This way, you enjoy using your lathe for a long time!”}}]}