Have you ever wondered how a lathe works so smoothly? It’s all about the finer details, like the cross slide gib adjustment. This adjustment might sound complicated, but it plays a big role in making sure the lathe moves just right.

Imagine trying to cut wood with a tool that keeps slipping. Frustrating, right? When the gib is not set properly, you could lose precision and ruin your work. That’s why knowing how to adjust the cross slide gib is so important!

Did you know that even small changes in the gib can make a huge difference? A little adjustment can lead to a smoother, more accurate cut. In this article, we’ll guide you through the simple steps to adjust your lathe’s cross slide gib.

So, are you ready to make your lathe work better? Let’s dive in and learn about this essential tool adjustment!

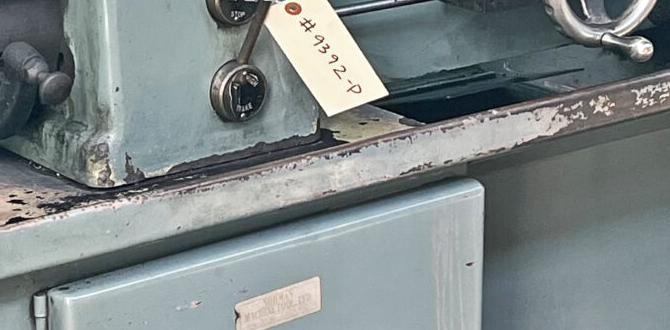

Lathe Cross Slide Gib Adjustment: Perfecting Your Setup Lathe Cross Slide Gib Adjustment Is An Essential Procedure For Ensuring The Precision And Smooth Operation Of A Lathe Machine. Proper Adjustment Of The Gib Plays A Significant Role In Maintaining The Accuracy Of Cuts And Extending The Lifespan Of The Machine. Below, We Will Explore The Importance Of This Adjustment, The Steps To Carry It Out, And The Benefits It Brings To Your Machining Projects. Understanding Lathe Cross Slide Gibs The Gib Is A Sliding Piece That Helps Secure The Movable Parts Of The Lathe, Such As The Cross Slide. It Helps In Providing Stability And Support, Preventing Any Unwanted Movement During Operation. Understanding How To Adjust The Gib Correctly Can Lead To A Significant Improvement In Machining Performance. Why Adjusting Gibs Is Important 1. **Precision**: Over Time, The Gib May Wear Down Or Become Loose, Leading To Inaccuracies In Machining. Adjusting The Gib Can Restore Precision. 2. **Smooth Operation**: A Properly Adjusted Gib Allows For Smooth Movement Of The Cross Slide, Enhancing Ease Of Use And Reducing Operator Fatigue. 3. **Longer Tool Life**: When The Gib Is Correctly Set, It Reduces Undue Stress On The Tool And The Machine, Which Can Extend The Life Of Both. Steps For Lathe Cross Slide Gib Adjustment 1. **Preparation**: Ensure The Lathe Is Powered Down And Completely Safe To Work On. Use A Clean Cloth To Wipe Down The Gib Area. 2. **Check For Play**: Move The Cross Slide Back And Forth. If You Notice Excessive Play, It Indicates That An Adjustment Is Necessary. 3. **Loosen The Gib Screws**: Locate The Screws Holding The Gib In Place, Usually Located At The Ends Of The Cross Slide. Slightly Loosen Them To Allow For Adjustments. 4. **Adjust The Gib**: Using A Screwdriver Or An Appropriate Tool, Make Slight Adjustments To The Gib. Generally, Tightening The Gib Will Reduce Play, While Loosening Can Increase Movement. 5. **Test Movement**: After Adjustments, Move The Cross Slide Again To Check For Smoothness And Precision. Repeat The Adjustment Process If Necessary. 6. **Secure The Screws**: Once Satisfied With The Adjustment, Retighten The Gib Screws Firmly To Secure The Gib In Place. Benefits Of Proper Gib Adjustment When Performed Correctly, Lathe Cross Slide Gib Adjustment Can Lead To: – Improved Accuracy In Machining Tasks. – A Smoother And Easier Operation, Allowing For Greater Efficiency. – A More Extended Lifespan For Both The Lathe And Cutting Tools. Conclusion Mastering Lathe Cross Slide Gib Adjustment Is Key To Optimized Lathe Operation. Regular Checks And Adjustments Can Lead To Long-Term Success In Your Machining Endeavors, Ensuring That Every Cut Is As Precise As Possible. With The Right Approach, You Can Enhance The Performance Of Your Lathe, Making Your Work More Efficient And Enjoyable.

Lathe Cross Slide Gib Adjustment

Adjusting the lathe cross slide gib is crucial for smooth operation. A loose gib can make your cuts rough and uneven. It’s like trying to ride a bike with a flat tire—hard and uncomfortable! Proper adjustment keeps the tool in line, ensuring precision. To adjust, start by locating the gib screws. Tightening these will reduce play and improve control. Remember, too tight can also cause problems. Finding the right balance is key. Want your lathe to produce the best results? Adjust the gib!Understanding the Lathe Cross Slide Mechanism

Explanation of the cross slide function in lathe operations.. Importance of the gib system in maintaining precision and stability..The cross slide on a lathe helps move the cutting tool side to side. This allows for precise shaping of materials. The gib system is important too. It keeps the cross slide steady and accurate. If the gib is loose, the lathe can make mistakes, leading to uneven cuts. A well-adjusted gib ensures smooth operation and keeps your work neat.

Why is the gib system important?

The gib system ensures the lathe operates smoothly, allowing for precise cuts and stability during machining.- Prevents side-to-side motion that can affect quality.

- Maintains precise alignment of the tool.

- Reduces wear and tear over time.

Identifying Signs of Worn or Misaligned Gibs

Common indicators that gib adjustment is necessary.. How to check for wear and alignment issues..Gibs help the lathe slide smoothly. However, if they wear out or misalign, the lathe’s movement may become rough. Look for these common signs of trouble:

- Uneven cutting on workpieces.

- Difficulty moving the cross slide.

- Visible play or looseness in slides.

- Strange noises during operation.

To check for these issues, observe the parts closely. Run the machine slowly and feel for sticking points. Regular checks can help keep your lathe working well.

How do I know if my gibs are worn?

Look for uneven cuts, sticking movement, or loose slides.

Tools Required for Gib Adjustment

List of tools needed for effective adjustment.. Safety equipment to consider during the process..When adjusting the gib on a lathe, you need the right tools. Start with basic tools like:

- Wrenches for loosening and tightening screws.

- Allen keys for hex screws.

- Screwdrivers for adjusting small parts.

- Feeler gauges to check spacing precisely.

Don’t forget safety gear! Always wear:

- Safety glasses to protect your eyes.

- Gloves to keep your hands safe.

Using these tools and safety items will help you make your adjustments successfully!

What tools are important for gib adjustment?

You will need wrenches, Allen keys, screwdrivers, and feeler gauges for a successful gib adjustment. These tools help you make the correct changes easily. Don’t forget to wear safety glasses and gloves while you work!

Step-by-Step Guide to Adjusting the Lathe Cross Slide Gib

Detailed instructions for loosening and adjusting gib screws.. Techniques for achieving proper tension and alignment..Adjusting the lathe cross slide gib is easier than pie, but it takes a bit of care. First, use a wrench to loosen the gib screws. Remember, do not turn them too much or your slide might feel like a wobbly jelly! Next, check the gib’s tension. You want it snug, not tight—like a hug from your favorite teddy bear. Lastly, align everything until it moves smoothly. A well-adjusted gib will make your lathe work like a dream!

| Step | Action |

|---|---|

| 1 | Loosen gib screws |

| 2 | Adjust tension |

| 3 | Align slide |

Best Practices for Maintaining Cross Slide Gibs

Regular maintenance tips to prolong gib life.. Recommendations for lubricants and cleaning methods..Taking care of your cross slide gibs keeps them happy and functional! Regular inspections are key. Look for wear and tear like a hawk checks the sky. Use light machine oil for lubrication; it helps gibs slide smoothly like a well-oiled slide at the playground. Clean with a soft cloth, avoiding harsh chemicals that might think they’re Carl the Cleaning Robot but only cause trouble!

| Maintenance Task | Recommendation |

|---|---|

| Inspection | Check weekly for wear |

| Lubrication | Use light machine oil |

| Cleaning | Soft cloth, no harsh chemicals |

Common Mistakes to Avoid During Gib Adjustment

Frequent pitfalls that can lead to improper adjustment.. Tips for troubleshooting adjustments and ensuring accuracy..Adjusting the gib can feel a bit like trying to find a squirrel in a snowstorm. Common mistakes to avoid involve cranking too hard or loose bolts. Tightening the gib too much can cause jams while being too loose leads to wobbly slides. Always check the alignment after adjustments. If things feel off, check your measurements. Remember, measure twice, adjust once! Here’s a handy table to guide you:

| Common Mistake | Issue | Tip |

|---|---|---|

| Tightening Too Much | Causes jams | Loosen slightly, test movement |

| Not Checking Alignment | Wobbly operation | Use a level, adjust as needed |

| Skipping Measurements | Inaccurate adjustments | Always measure first |

Following these tips will help you avoid typical traps. Happy adjusting, and may your lathe slide smoothly!

Resources for Further Learning

Recommended books, articles, and tutorials on gib adjustment.. Online forums and communities for troubleshooting and advice..Learning more about gib adjustment can help improve your skills. Check out these great resources:

- Books: Search for titles on machine maintenance.

- Articles: Look for detailed guides on gib adjustments.

- Tutorials: Find video tutorials on platforms like YouTube.

You can also join online forums and communities. They provide help for questions and troubleshooting. Ask for advice and share your own tips with others!

What are good resources for gib adjustment?

Books, articles, and tutorials all provide useful information about gib adjustments. Online communities are great for seeking advice and sharing experiences. These resources can help you learn and fix issues faster.

Conclusion

To adjust the lathe cross slide gib, you need to understand its role in smooth movement. Proper adjustments reduce play and improve precision. Check for wear regularly and make small tweaks to maintain optimal performance. By staying proactive, you can enhance your machining results. Keep learning about lathe maintenance for even better projects ahead!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cross Slide Gib Adjustment:Sure! Here are five related questions about lathe cross slide gib adjustment: 1. What is a cross slide on a lathe? A cross slide helps move the tool side to side smoothly when cutting. 2. Why do we need to adjust the gib? We adjust the gib to keep everything tight, so the tool moves easily without wobbling. 3. How do you know if the gib needs adjusting? If the tool feels loose or jerky, it’s time to check and adjust the gib. 4. Can you adjust the gib by yourself? Yes, you can adjust the gib using a simple tool like a wrench. 5. What happens if the gib is too loose? If the gib is too loose, the tool might not cut straight, which makes a mess.

Sure! Please share the question you’d like me to answer, and I’ll be happy to help!

What Is The Purpose Of The Gib In The Lathe Cross Slide Assembly?The gib helps hold parts of the lathe cross slide tightly together. It makes sure everything moves smoothly and doesn’t wiggle. When you turn the handle, the gib keeps the slide steady. This way, we can cut metal accurately. It’s like a strong friend that helps keep things in place while you work!

How Can You Identify If The Gib On A Lathe Cross Slide Needs Adjustment?You can tell if the gib on a lathe cross slide needs adjusting by looking for gaps. Gaps mean the cross slide might be too loose. You can also check if the slide moves too easily or gets stuck. If it doesn’t stay in place when you want it to, it’s time for an adjustment.

What Tools Are Required To Adjust The Lathe Cross Slide Gib Properly?To adjust the lathe cross slide gib, you need a few tools. First, grab a wrench to loosen the screws. Next, use a screwdriver to adjust the gib. Finally, a feeler gauge can help check if it’s tight enough. With these tools, you can make your lathe work better!

What Are The Potential Consequences Of An Improperly Adjusted Cross Slide Gib?If the cross slide gib is not adjusted right, your machine may not work well. You might get uneven cuts or scratches on your pieces. It can also make the machine hard to move. This can lead to mistakes in your project. In the end, you may waste time and materials.

Can You Describe The Steps Involved In Adjusting The Gib On A Lathe Cross Slide?To adjust the gib on a lathe cross slide, first, turn off the machine. Next, look for the gib screws on the side of the cross slide. Then, use a screwdriver to loosen the screws just a bit. After that, you can slide the cross slide back and forth. Finally, tighten the screws again to hold everything in place.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cross Slide Gib Adjustment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions about lathe cross slide gib adjustment: 1. What is a cross slide on a lathe? A cross slide helps move the tool side to side smoothly when cutting. 2. Why do we need to adjust the gib? We adjust the gib to keep everything tight, so the tool moves easily without wobbling. 3. How do you know if the gib needs adjusting? If the tool feels loose or jerky, it’s time to check and adjust the gib. 4. Can you adjust the gib by yourself? Yes, you can adjust the gib using a simple tool like a wrench. 5. What happens if the gib is too loose? If the gib is too loose, the tool might not cut straight, which makes a mess.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Gib In The Lathe Cross Slide Assembly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gib helps hold parts of the lathe cross slide tightly together. It makes sure everything moves smoothly and doesn’t wiggle. When you turn the handle, the gib keeps the slide steady. This way, we can cut metal accurately. It’s like a strong friend that helps keep things in place while you work!”}},{“@type”: “Question”,”name”: “How Can You Identify If The Gib On A Lathe Cross Slide Needs Adjustment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell if the gib on a lathe cross slide needs adjusting by looking for gaps. Gaps mean the cross slide might be too loose. You can also check if the slide moves too easily or gets stuck. If it doesn’t stay in place when you want it to, it’s time for an adjustment.”}},{“@type”: “Question”,”name”: “What Tools Are Required To Adjust The Lathe Cross Slide Gib Properly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the lathe cross slide gib, you need a few tools. First, grab a wrench to loosen the screws. Next, use a screwdriver to adjust the gib. Finally, a feeler gauge can help check if it’s tight enough. With these tools, you can make your lathe work better!”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of An Improperly Adjusted Cross Slide Gib?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the cross slide gib is not adjusted right, your machine may not work well. You might get uneven cuts or scratches on your pieces. It can also make the machine hard to move. This can lead to mistakes in your project. In the end, you may waste time and materials.”}},{“@type”: “Question”,”name”: “Can You Describe The Steps Involved In Adjusting The Gib On A Lathe Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the gib on a lathe cross slide, first, turn off the machine. Next, look for the gib screws on the side of the cross slide. Then, use a screwdriver to loosen the screws just a bit. After that, you can slide the cross slide back and forth. Finally, tighten the screws again to hold everything in place.”}}]}