Mastering The Lathe Cross-Slide Scraping Technique

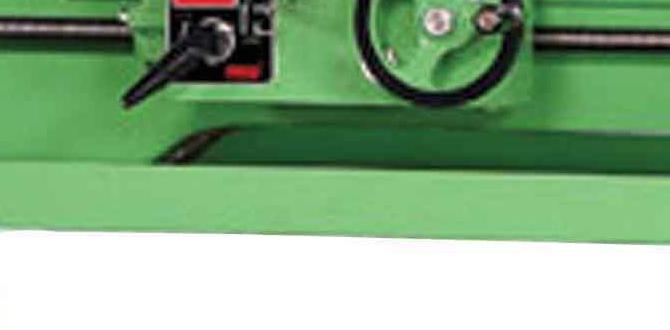

Lathe Cross-Slide Scraping Technique

The lathe cross-slide scraping technique helps improve tool performance. Using this method, you can achieve a smooth and accurate finish. Imagine taking a rough surface and turning it into something gleaming and precise. Effective scraping reduces friction and wear. This technique requires careful control for the best results. Did you know that the proper scraping can extend the life of your lathe? Mastering it brings a rewarding touch to any metalworking project.Understanding the Basics of Lathe Cross-Slide Scraping

Definition of lathe crossslide scraping. Importance in precision machining and tool maintenance.Lathe cross-slide scraping is like giving your machine a spa day. This technique smooths out surfaces to ensure everything fits perfectly. Think of it as tuning a guitar; when it’s done well, the sound is sweet. Precision machining relies on this method to produce accurate parts. Without it, tools can wear down faster than your favorite shirt in the dryer. Proper scraping not only enhances tool life but leads to better performance.

| Key Points | Importance |

|---|---|

| Surface smoothness | Enhances tool fit |

| Tool maintenance | Increases longevity |

| Precision machining | Improves accuracy |

Tools and Materials Required for Scraping

Essential tools: scrapers, gauges, and measuring instruments. Recommended materials for effective scraping.To start scraping, you’ll need some important tools. First, get a scraper. This tool helps smooth surfaces. Next, have gauges on hand to check how flat you make things. A good measuring instrument is also key for accuracy.

For effective scraping, consider these materials:

- High-quality steel for scrapers

- Precision measuring tools like calipers

- Fine lubricants to reduce friction

Using the right tools makes your work easier and produces better results! Now you’re ready to scrape like a pro!

What tools do you need for lathe scraping?

You need scrapers, gauges, and measuring instruments. These tools ensure your scraping is accurate and effective.

Step-by-Step Guide to the Scraping Technique

Detailed procedures for preparing the lathe. Techniques for scraping and achieving a flat surface.Start by cleaning your lathe. Remove any dust and debris. This helps you work smoothly. Next, choose the right tools for scraping. Use a flat scraper for the best results. Check the surface with a straight edge to find high and low spots. Carefully scrape the high spots until it is even. Repeat this step. Continue checking until the surface feels flat. Always wear safety gear while working.

How do you prepare the lathe for scraping?

To prepare the lathe, ensure it is clean, check for wear, and gather the right tools. Measure the surface using a straight edge to identify any uneven areas.

Steps to Check the Lathe:

- Clean the lathe surface

- Gather scraping tools

- Inspect with a straight edge

Common Mistakes to Avoid in Cross-Slide Scraping

Misalignment issues and their impact on machining. Overscraping and its consequences.One common mistake is failing to align the cross-slide correctly. Poor alignment can cause uneven cuts. This impacts the piece being machined, leading to poor results. Another issue is overscraping. This happens when too much material is removed. As a result, the slide may become loose. This reduces accuracy and can ruin the machine.

What is the effect of misalignment on machining?

Misalignment leads to inaccurate cuts. This can make parts not fit together well. It also wastes material and time.

What happens if I overscrape?

- Reduces slide stability.

- Causes accuracy issues.

- Can damage the machine.

Maintenance Tips for Longevity of Scraped Surfaces

Best practices for maintaining scraped surfaces in good condition. Recommended lubricants and cleaning methods.Keeping scraped surfaces in top shape is like giving your lathe a spa day. Regular cleaning is key, so wipe off grime with a soft cloth. Use mineral oil or light machine oil for lubrication—think of it as a soothing massage for your machine. Avoid harsh chemicals; they’re like bad junk food for your lathe. Here’s a quick table for your maintenance routine:

| Task | Frequency | Notes |

|---|---|---|

| Clean Scraped Surfaces | Every Use | Use a soft cloth. |

| Apply Lubricant | Weekly | Mineral oil is a winner! |

| Check for Wear | Monthly | Look for scratches. |

Following these habits keeps your lathe happy and running smoothly. After all, a well-cared-for machine is a happy machine!

Resources and Further Reading on Scraping Techniques

Suggested books, videos, and online courses for deeper knowledge. Communities and forums for ongoing learning and support.For anyone keen to master scraping techniques, there are some fantastic resources available. Books like “The Art of Scraping” and videos on YouTube can give you a great start. Online courses offer step-by-step lessons. Also, joining communities and forums can help you learn from others. It’s like having a toolbox full of tips!

| Resource Type | Title | Link |

|---|---|---|

| Book | The Art of Scraping | Buy Here |

| Video | Scraping Techniques 101 | Watch Now |

| Online Course | Scraping Secrets | Enroll Today |

| Forum | Scraping Masterminds | Join the Talk |

These tools can turn your scraping dreams into reality – or at least keep the lathe from turning into a giant paperweight!

Conclusion

In summary, the lathe cross-slide scraping technique is important for precision in machining. It helps improve surface finish and accuracy. By learning this skill, you can enhance your woodworking or metalworking projects. Start practicing these techniques, explore tutorials, and refine your skills. With patience and practice, you’ll see great results in your work!FAQs

What Is The Purpose Of Precision Scraping In The Lathe Cross-Slide, And How Does It Improve Machining Accuracy?Precision scraping helps make the lathe cross-slide smooth and even. This means parts move better without getting stuck. When we do this, it makes the machine work more accurately. Better accuracy means your shapes and sizes will be just right, not too big or too small. So, precision scraping helps us make things that fit perfectly!

What Tools And Materials Are Commonly Used For Scraping A Lathe Cross-Slide?To scrape a lathe cross-slide, we use some special tools and materials. A scraper tool helps us shape the metal. We also need a flat surface to check if it’s even. Some people use oil or grease to help things move smoothly. Finally, a ruler helps us measure and make sure everything is right.

What Are The Steps Involved In Assessing The Flatness Of A Lathe Cross-Slide Before Starting The Scraping Process?First, take a clean ruler or a straight edge and place it on the cross-slide. Next, check if there are any gaps between the cross-slide and the ruler. If you see light between them, the surface is not flat. Then, use a feeler gauge, which is a thin tool, to measure the gaps. Finally, note down any high or low spots to fix later when scraping.

How Can You Determine The Appropriate Scraping Pattern And Angle For Effective Material Removal On A Lathe Cross-Slide?To find the right scraping pattern and angle on a lathe cross-slide, start by checking the surface you need to clean. Look at how rough or smooth it is. You want to use a pattern that helps you remove material evenly. Hold the scraper at a slight angle to make it work better. Practice a bit to see what feels right and gives you the best finish!

What Are Some Common Mistakes To Avoid When Scraping A Lathe Cross-Slide, And How Can They Impact The Final Machining Performance?When you scrape a lathe cross-slide, avoid these mistakes: don’t rush your work, use the wrong tool, or forget to check for flatness. Rushing can lead to uneven surfaces. Using the wrong tool can cause damage. Not checking for flatness can affect how well the lathe works. These mistakes can make your final results worse and your machine less accurate.