Have you ever wondered how machines create perfectly shaped pieces from metal or wood? One key to this amazing process lies in the lathe cutting tool materials used by skilled craftsmen. These tools help shape everything from parts of cars to decorative furniture.

Imagine making a beautiful wooden bowl or a shiny metal gear. Without the right materials for cutting, these creations would be quite hard to achieve. Did you know that the material of a lathe cutting tool can greatly affect its performance? Choosing the right type can make a huge difference in how smooth or rough your finished product is.

In this article, we will explore different lathe cutting tool materials. We will discover how each type helps craftsmen create their amazing work. Get ready to dive into the world of crafting with lathes and learn why the right tool makes all the difference!

Lathe Cutting Tool Materials: Types And Properties Explained

Lathe Cutting Tool Materials

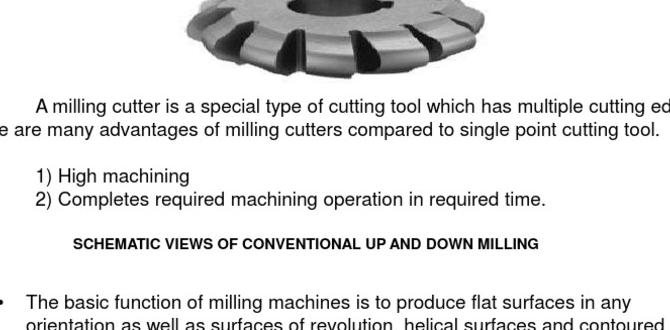

Are you curious about what makes a lathe cutting tool effective? Lathe cutting tool materials are crucial in shaping metals and plastics. Common materials include high-speed steel (HSS), carbide, and ceramic. Each type has unique properties that determine its durability and cutting ability. Did you know that carbide tools can last up to six times longer than HSS tools? Understanding these materials helps machinists choose the right tool for various tasks.Cemented Carbide Tools

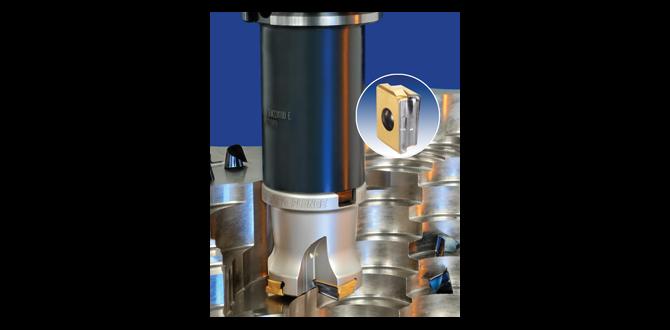

Characteristics and advantages of cemented carbide tools.. Common applications and suitability for different machining tasks..Cemented carbide tools are known for their strength and durability. They can withstand high temperatures and are resistant to wear. This makes them a popular choice in many industries. The benefits include:

- High hardness for precision cutting.

- Longevity that reduces tool change times.

- Versatility for various machining tasks.

Cemented carbide tools work well in applications like machining metals, plastics, and composites. They excel in tasks such as turning, milling, and drilling. Their ability to perform under tough conditions makes them ideal for both small shops and large factories.

What are the advantages of cemented carbide tools?

Cemented carbide tools offer high resistance to wear, making them last longer than many other types of tools. They also maintain sharpness better, leading to smoother cuts and better quality parts.

High-Speed Steel (HSS) Tools

Description of highspeed steel and its properties.. Advantages of HSS in cutting operations and when to use it..High-speed steel (HSS) is a super strong material used for cutting tools. It can slice through metal like a hot knife through butter! HSS stays sharp longer than regular steel. It’s tough and heat-resistant, allowing it to cut quickly without losing its edge. Because of this, it’s perfect for tasks where speed matters. Use HSS tools for precise cuts and tough materials. Remember, dull tools are like a bad haircut – nobody likes them!

| Property | Benefit |

|---|---|

| Durability | Lasts longer than standard steel |

| Heat Resistance | Works well in high-temp conditions |

| Versatility | Great for various cutting operations |

Ceramic Cutting Tools

Properties of ceramic materials in lathe cutting tools.. Benefits of using ceramic tools for specific materials and conditions..Ceramic cutting tools are special because they are tough and last a long time. They can handle high temperatures and keep their shape. This makes them great for cutting hard materials like metal.

- High hardness: They resist wear and tear.

- Temperature stability: They don’t change shape when hot.

- Low friction: They cut smoothly and quickly.

These tools shine in difficult conditions. They work well in dry machining where coolant is not used. Many choose ceramic tools for high-speed operations. This choice means less downtime and stronger performance.

What are the benefits of ceramic cutting tools?

Ceramic tools can cut through tough materials faster and last longer than other types. They help you finish projects quickly and efficiently.

Diamond Cutting Tools

Explanation of synthetic and natural diamond tools.. Key benefits and applications in precision machining..Diamond cutting tools are special equipment used in machining. They can be made from synthetic or natural diamonds. Synthetic diamonds are man-made and very tough, while natural diamonds come from the earth and are known for their hardness.

Using diamond tools has big benefits. They last longer than other materials and cut very precisely. This makes them great for shaping metal and other hard materials.

- Lasts longer than steel or carbide.

- Provides high precision for detailed work.

- Reduces heat during cutting.

This means less time for replacements and better products overall. In industries where precision is key, diamond tools are a top choice.

What are the benefits of diamond cutting tools?

Diamond cutting tools are durable, precise, and efficient, making them perfect for many machining tasks.

Factors Affecting Material Selection

Considerations for choosing the right cutting tool material based on the application.. Impact of workpiece materials and machining conditions on tool life..Choosing the right material for cutting tools is important. It affects how well the tool works. Some key things to think about include:

- Application: Think about the part you need to cut. Different jobs need different materials.

- Workpiece Material: The type of metal or plastic you are cutting impacts tool wear.

- Machining Conditions: Temperature and pressure during cutting change how long the tool lasts.

Understanding these factors can help in picking the best tool material for your work.

Why does the material of the workpiece matter when choosing cutting tools?

The material of the workpiece can determine the lifespan of the cutting tool. Different materials wear out tools at different rates.

Future Trends in Cutting Tool Materials

Innovations in material science and its implications for lathe cutting tools.. Predictions for sustainable and highperformance materials in the industry..Exciting things are brewing in the world of lathe cutting tools! Innovations in material science are making tools stronger and longer-lasting. Imagine cutting through metal like it’s butter! Scientists are exploring new, eco-friendly materials that could help the planet too. It’s like every tool could be a superhero of sustainability. Here’s a peek into future trends:

| Material | Benefits |

|---|---|

| Carbon Nanotubes | Stronger and lighter tools |

| Biocomposite Materials | Eco-friendly and durable |

Experts think more industries will use these sustainable options. The future looks bright, and cutting tools are gearing up for a green makeover! Who knew science could be this cool?

Conclusion

In summary, lathe cutting tools come in various materials, each with strengths. High-speed steel is tough and reliable, while carbide offers great hardness and precision. Understanding these options helps you choose the right tool for your projects. Explore more about lathe tools online, or visit a local workshop to see them in action. Happy machining!FAQs

What Are The Different Types Of Materials Commonly Used For Lathe Cutting Tools, And What Are Their Specific Properties?Lathe cutting tools are made from different materials. These include high-speed steel (HSS), carbide, and ceramic. High-speed steel is tough and can handle heat well. Carbide is very hard, making it last a long time. Ceramic tools are also hard and can cut quickly but may break easily if dropped.

How Do Carbide Cutting Tools Compare To High-Speed Steel (Hss) Tools In Terms Of Performance And Longevity When Used In Lathe Operations?Carbide cutting tools are better than high-speed steel (HSS) tools for lathe work. They stay sharp longer and can cut faster. This means you can finish your projects quicker with carbide tools. HSS tools wear out more quickly, so you’ll need to change them often. Overall, carbide tools last longer and perform better.

What Are The Advantages And Disadvantages Of Using Coated Cutting Tools In Lathe Machining Processes?Coated cutting tools help us cut metal better and last longer. They can make smooth lines and resist heat. However, they can cost more money. Sometimes, if they chip, you must replace them quickly. So, they are great but can be expensive to fix.

How Does Tool Geometry Influence The Effectiveness Of Lathe Cutting Tools Made From Different Materials?The shape of a lathe cutting tool, called tool geometry, affects how well it cuts materials. A sharp edge helps the tool cut smoothly. If the tool is too thick or has the wrong angle, it can get stuck or break. Different materials, like steel or carbide, also change how well the tool works. So, the right shape and material together help us cut better and faster!

What Advancements In Cutting Tool Materials Have Been Made In Recent Years, And How Do They Impact Lathe Machining Efficiency And Precision?Recently, new materials for cutting tools have been made, like super hard ceramics and improved metals. These materials last longer and cut better. This means that when we use lathes, or machines that shape metal, we can work faster and make better shapes. Better cutting tools help us create things more accurately and save time.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Different Types Of Materials Commonly Used For Lathe Cutting Tools, And What Are Their Specific Properties?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe cutting tools are made from different materials. These include high-speed steel (HSS), carbide, and ceramic. High-speed steel is tough and can handle heat well. Carbide is very hard, making it last a long time. Ceramic tools are also hard and can cut quickly but may break easily if dropped.”}},{“@type”: “Question”,”name”: “How Do Carbide Cutting Tools Compare To High-Speed Steel (Hss) Tools In Terms Of Performance And Longevity When Used In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Carbide cutting tools are better than high-speed steel (HSS) tools for lathe work. They stay sharp longer and can cut faster. This means you can finish your projects quicker with carbide tools. HSS tools wear out more quickly, so you’ll need to change them often. Overall, carbide tools last longer and perform better.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using Coated Cutting Tools In Lathe Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Coated cutting tools help us cut metal better and last longer. They can make smooth lines and resist heat. However, they can cost more money. Sometimes, if they chip, you must replace them quickly. So, they are great but can be expensive to fix.”}},{“@type”: “Question”,”name”: “How Does Tool Geometry Influence The Effectiveness Of Lathe Cutting Tools Made From Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape of a lathe cutting tool, called tool geometry, affects how well it cuts materials. A sharp edge helps the tool cut smoothly. If the tool is too thick or has the wrong angle, it can get stuck or break. Different materials, like steel or carbide, also change how well the tool works. So, the right shape and material together help us cut better and faster!”}},{“@type”: “Question”,”name”: “What Advancements In Cutting Tool Materials Have Been Made In Recent Years, And How Do They Impact Lathe Machining Efficiency And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Recently, new materials for cutting tools have been made, like super hard ceramics and improved metals. These materials last longer and cut better. This means that when we use lathes, or machines that shape metal, we can work faster and make better shapes. Better cutting tools help us create things more accurately and save time.”}}]}