Have you ever wondered how to improve your lathe’s performance? Installing a digital micrometer stop can make a big difference. It helps you measure with accuracy and speed, saving you time and effort.

Imagine working on a project where every cut counts. You want it to be perfect, right? A digital micrometer stop can help you achieve that level of precision. It’s like having a smart friend guiding you in the workshop.

But how do you install one? It might seem tricky at first. However, with the right steps, you can do it easily. Knowing how to install a lathe digital micrometer stop can turn your projects into real masterpieces. Are you ready to dive in and learn more?

Lathe Digital Micrometer Stop Install: A Step-By-Step Guide

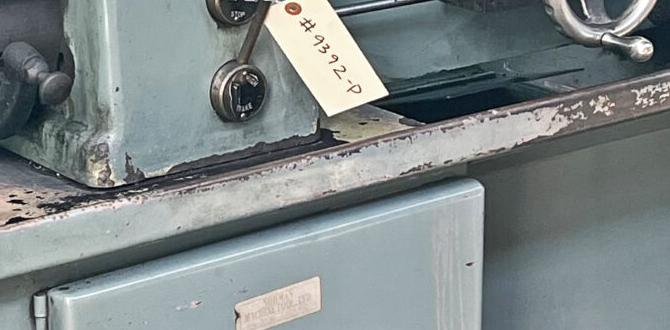

Lathe Digital Micrometer Stop Install

Installing a lathe digital micrometer stop can simplify precise measurements, making your projects easier. This tool helps you achieve consistent cuts every time. Have you ever struggled with repeating measurements? A micrometer stop can solve that issue. It’s simple to install, requires minimal tools, and enhances your lathe’s functionality. Imagine the time you’ll save when you don’t have to measure twice! With a digital micrometer stop, your work becomes more efficient and accurate, bringing your projects to the next level.Understanding Lathe Digital Micrometer Stops

Definition and purpose of a digital micrometer stop. Importance of accuracy in lathe operations.A digital micrometer stop is a tool that helps measure small lengths accurately on a lathe. It ensures the proper position for cutting and shaping materials. Here’s why it’s important:

- Accuracy: Good measurements lead to better results.

- Efficiency: Saves time by preventing mistakes.

- Consistency: Helps repeat the same cuts reliably.

In lathe operations, small errors can cause big problems. Using a digital micrometer stop improves both safety and quality. Remember, precise measurements are key for success!

What is the purpose of a digital micrometer stop?

The purpose of a digital micrometer stop is to ensure accurate measurements while cutting on a lathe. This helps you maintain the right length and depth for each cut.

Tools and Materials Needed for Installation

List of essential tools for installation. Recommended micrometer stop models for various lathes.To install a lathe digital micrometer stop, you need a few tools and materials. Here’s a quick list:

- Wrench

- Screwdriver

- Drill

- Measuring tape

For micrometer stop models, consider these options:

- Model A for small lathes

- Model B for medium lathes

- Model C for large lathes

Having the right tools makes the job easier and faster!

Why are tools important for installation?

Using proper tools ensures safety and efficiency during installation. This helps prevent mistakes and allows for a smoother setup process.

Preparing the Lathe for Installation

Steps to clean and inspect the lathe prior to installation. Safety considerations and precautions.Before you install anything on your lathe, cleaning is key! Start by wiping away dust and oil. Check if any parts are loose or damaged; a tight machine is a happy machine! Safety is also super important. Always wear goggles and keep fingers clear of moving parts. You wouldn’t want to turn your hand into a pretzel!

| Step | Action |

|---|---|

| 1 | Clean the lathe surfaces. |

| 2 | Inspect for any damage. |

| 3 | Check loose bolts and screws. |

| 4 | Wear safety goggles. |

| 5 | Keep hands clear of moving parts. |

Following these steps can help ensure a smooth installation. Remember, safety and cleanliness go hand in hand like peanut butter and jelly!

Step-by-Step Installation Process

Detailed procedure for mounting the digital micrometer stop. Setting up the digital display and calibrating it.To install a digital micrometer stop, follow these steps:

- Begin by securely mounting the stop on the lathe.

- Make sure it aligns perfectly with the spindle.

- Next, connect the digital display to the micrometer. Ensure all wires are snug and safe.

- Now, turn on the machine. Check if the screen lights up.

- Calibrate the micrometer by measuring a known size. Adjust it as needed until it matches.

After following these steps, your setup should be complete. Now, you can measure with precision!

How to calibrate the digital micrometer?

Calibrate it by inputting the measurement of a standard gauge block. Adjust the micrometer to read accurately based on this known measurement.

Troubleshooting Common Installation Issues

Identification of typical problems during installation. Solutions and tips for a successful setup.Installing your lathe digital micrometer stop might feel like a puzzle with missing pieces. Common problems can include misalignment or loose screws. Don’t panic! First, check if everything is snug and straight. If it resembles a wobbly tower, tighten those screws. Need a quick reference? Here’s a handy table:

| Problem | Solution |

|---|---|

| Misalignment | Recheck position and adjust. |

| Loose screws | Tighten firmly. |

Keep your workspace clean too! It’s much easier to find parts without a jungle of tools. Remember, the goal is smooth sailing, not an episode of “Survivor: Workshop Edition.”

Maintaining Your Lathe Digital Micrometer Stop

Best practices for keeping the micrometer stop in optimal condition. Regular checkups and recalibration guidelines.Taking care of your micrometer stop keeps it running smoothly and your projects precise! First, check it regularly for dirt or wear. Clean it gently with a soft cloth. Recalibrating often is key; do it every few months or whenever something feels off. Remember, a happy micrometer stop means more accurate measurements. Don’t think of it as a chore; think of it as keeping your tool in tip-top shape! You wouldn’t let your favorite toy gather dust, would you?

| Best Practices | Frequency |

|---|---|

| Regular Cleaning | Every Use |

| Recalibrate | Every 3 Months |

| Visual Check for Damage | Monthly |

Advantages of Using a Digital Micrometer Stop

Enhanced precision and efficiency in machining. Comparison with traditional micrometer stops.Imagine a world where your measurements are spot on every time! Using a digital micrometer stop can make that dream come true. It brings enhanced precision to machining. Forget the guesswork; it shows numbers clearly and quickly. In comparison to traditional micrometer stops, digital ones save time and reduce errors. You can’t argue with that! Let’s break it down with a quick look:

| Feature | Digital Micrometer Stop | Traditional Micrometer Stop |

|---|---|---|

| Precision | High | Medium |

| Ease of Use | Very Easy | A Bit Tricky |

| Speed | Fast | Slow |

So, why choose the old way when the future is at your fingertips? With a digital micrometer stop, every project becomes smoother. Happy measuring!

Frequently Asked Questions about Installation

Common queries and expert answers related to installation. Additional resources for further learning and support.Installing a lathe digital micrometer stop can raise some eyebrows and questions. Many people wonder how to get started without making mistakes. A few key questions pop up often. First, folks ask, “What tools do I need?” and the answer is simple: a wrench, a screwdriver, and lots of patience! Another common query is about the **accuracy of measurements**. A well-installed micrometer stop can boost precision like a superhero in a comic book!

For those looking to learn more, tutorials and videos are great resources. And remember, practice makes perfect! Below is a handy table with questions and answers you might find helpful:

| Question | Answer |

|---|---|

| How do I know if my stop is installed correctly? | Check the calibration and ensure it sets the depth accurately. |

| Can I install it myself, or do I need help? | You can totally DIY! But if you feel stuck, call a buddy. |

So, grab your tools and get ready for some fun with your lathe digital micrometer stop installation!

Conclusion

In summary, installing a lathe digital micrometer stop is important for accurate measurements. You need to choose the right micrometer and follow clear steps. With practice, you will improve your skills and projects. Don’t hesitate to explore more guides or videos online for better understanding. Start your installation today for precise and efficient work!FAQs

Here Are Five Related Questions On The Topic Of Installing A Digital Micrometer Stop On A Lathe:A digital micrometer stop helps you measure things accurately on a lathe, which is a machine that shapes materials. To install it, first, turn off the lathe and gather your tools. You’ll want to attach the stop securely to the machine. After that, set the measurement you need on the digital micrometer. Finally, test it to make sure it works right!

Sure! Please give me the question you’d like me to answer.

What Tools And Materials Do I Need To Install A Digital Micrometer Stop On My Lathe?To install a digital micrometer stop on your lathe, you need a few basic tools and materials. First, get a digital micrometer stop, which helps measure distances. You’ll also want a wrench to tighten things. Additionally, use a ruler for accurate measurements. Finally, have some screws or bolts ready to secure everything in place.

How Do I Properly Align The Digital Micrometer Stop For Accurate Measurements During Turning?To align the digital micrometer stop properly, first, make sure it’s clean and free of dirt. Then, place your workpiece in the machine. Slide the micrometer until it touches the piece lightly. Lock it in place to keep it steady. Finally, check the reading on the display; it should show the correct measurement.

What Are The Common Challenges Faced When Installing A Digital Micrometer Stop, And How Can I Overcome Them?When installing a digital micrometer stop, you might face a few challenges. First, the stop may not fit perfectly. To fix this, make sure measurements are correct before buying. Next, the batteries could die. Always check the batteries first and replace them if needed. Finally, parts might be hard to connect. Take your time and follow the instructions carefully.

How Do I Calibrate The Digital Micrometer Stop After Installation To Ensure Precision In My Lathe Work?To calibrate your digital micrometer stop, first, check that it’s properly installed. Next, take a measurement of a known size, like a metal block. If the reading isn’t correct, adjust the micrometer until it matches. Repeat this a few times to make sure it’s right. When it shows the right number, you’re ready to use it!

Can I Install A Digital Micrometer Stop On Any Type Or Model Of Lathe, Or Are There Specific Compatibility Considerations?You can’t install a digital micrometer stop on every lathe. Different lathes have different designs. You need to check if it fits yours. Always read the instructions to see if it’s compatible. If you’re not sure, ask a helpful person at a store or online.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Installing A Digital Micrometer Stop On A Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital micrometer stop helps you measure things accurately on a lathe, which is a machine that shapes materials. To install it, first, turn off the lathe and gather your tools. You’ll want to attach the stop securely to the machine. After that, set the measurement you need on the digital micrometer. Finally, test it to make sure it works right!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Tools And Materials Do I Need To Install A Digital Micrometer Stop On My Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a digital micrometer stop on your lathe, you need a few basic tools and materials. First, get a digital micrometer stop, which helps measure distances. You’ll also want a wrench to tighten things. Additionally, use a ruler for accurate measurements. Finally, have some screws or bolts ready to secure everything in place.”}},{“@type”: “Question”,”name”: “How Do I Properly Align The Digital Micrometer Stop For Accurate Measurements During Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the digital micrometer stop properly, first, make sure it’s clean and free of dirt. Then, place your workpiece in the machine. Slide the micrometer until it touches the piece lightly. Lock it in place to keep it steady. Finally, check the reading on the display; it should show the correct measurement.”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced When Installing A Digital Micrometer Stop, And How Can I Overcome Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When installing a digital micrometer stop, you might face a few challenges. First, the stop may not fit perfectly. To fix this, make sure measurements are correct before buying. Next, the batteries could die. Always check the batteries first and replace them if needed. Finally, parts might be hard to connect. Take your time and follow the instructions carefully.”}},{“@type”: “Question”,”name”: “How Do I Calibrate The Digital Micrometer Stop After Installation To Ensure Precision In My Lathe Work?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate your digital micrometer stop, first, check that it’s properly installed. Next, take a measurement of a known size, like a metal block. If the reading isn’t correct, adjust the micrometer until it matches. Repeat this a few times to make sure it’s right. When it shows the right number, you’re ready to use it!”}},{“@type”: “Question”,”name”: “Can I Install A Digital Micrometer Stop On Any Type Or Model Of Lathe, Or Are There Specific Compatibility Considerations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can’t install a digital micrometer stop on every lathe. Different lathes have different designs. You need to check if it fits yours. Always read the instructions to see if it’s compatible. If you’re not sure, ask a helpful person at a store or online.”}}]}