Have you ever struggled to read measurements while working on a lathe? It can be frustrating! A lathe digital readout arm mount might be just what you need. Imagine easily seeing accurate measurements without straining your eyes or guessing. Sounds great, right?

Lathe digital readout systems make machining work so much easier. They help you monitor your progress clearly. With a proper arm mount, your readout stays within easy reach. This means less time spent adjusting and more time crafting amazing projects.

Did you know that using a digital readout can improve your accuracy by a huge margin? It’s true! Whether you’re building furniture or precision parts, a lathe digital readout arm mount can make all the difference.

Are you ready to learn how you can benefit from this handy tool? Let’s dive into the details and discover why it’s a game-changer for every hobbyist and professional alike.

Lathe Digital Readout Arm Mount: Enhance Accuracy Today!

Lathe Digital Readout Arm Mount: Key Insights

A lathe digital readout arm mount enhances precision and control for machinists. It securely holds the digital display, giving clear measurements right where you need them. This upgrade simplifies the setup process and makes your work easier. Did you know that using a digital readout can cut down on errors? Imagine crafting a part with exact measurements without the stress of manual calculations. A digital readout arm mount truly modernizes your lathe experience!Benefits of Using a Digital Readout Arm Mount on Lathes

Improved accuracy and measurement consistency. Enhanced setup efficiency and reduced setup time.Using a digital readout arm mount on lathes offers great benefits. It improves accuracy and keeps measurements consistent. This means fewer mistakes and better results. It also makes setup faster, saving you valuable time. You can jump right into your work!

- Improved accuracy helps with precise cuts.

- Consistent measurements ensure quality results.

- Faster setups mean more time for other tasks.

- Reduced setup time helps you finish projects quicker.

What are the main advantages of digital readout arm mounts?

The main advantages include better accuracy and faster setup times. This technology reduces human error, leading to consistent results in every project.

Key Features to Look for in a Lathe Digital Readout Arm Mount

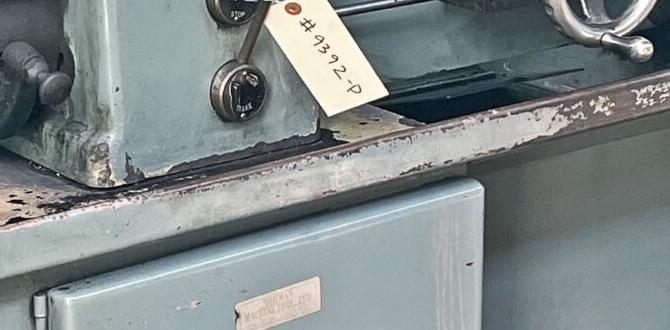

Durability and material quality. Compatibility with different lathe models.When choosing a lathe digital readout arm mount, you should check two main things. First, look for durability and material quality. You want it to last longer than your last New Year resolution! Second, ensure it is compatible with different lathe models. Nobody wants a mount that yoga stretches just to fit. A good mount will save you time and frustration, letting you focus on creating amazing things!

| Feature | Importance |

|---|---|

| Durability | Lasts longer, saves money |

| Material Quality | Resists wear and tear |

| Compatibility | Fits various lathe models |

Installation Guide for Lathe Digital Readout Arm Mounts

Stepbystep installation instructions. Common installation challenges and solutions.Installing a lathe digital readout arm mount can be easy! Here’s a simple guide:

- First, find the right spot on your lathe.

- Next, use a level to make sure it’s straight.

- Then, drill holes for screws.

- Finally, attach the readout arm securely.

Some challenges may pop up. If the arm wobbles, check the screws. If it doesn’t fit, adjust the position. Always keep tools handy. Remember, safety first!

What are common issues during installation?

Common problems include uneven mounts or loose parts. Tighten screws if something feels shaky. Use spacers for uneven spots. A proper fit is key to a smooth operation!

Maintenance Tips for Your Digital Readout Arm Mount

Routine maintenance practices to ensure longevity. Troubleshooting common issues.Keeping your digital readout arm mount in good shape is important for it to last long. Regular checks can prevent issues. Clean the mount often with a soft cloth. Look for loose parts and tighten them. Ensure all connections are secure to avoid errors. If you notice problems, check these common issues:

- Display issues: Check connections and batteries.

- Accuracy problems: Recalibrate the device.

- Unresponsive controls: Inspect for damage or debris.

Staying on top of these tasks keeps everything running smoothly.

What should I do if my readout is showing the wrong measurements?

Recalibrate the readout. This is often a simple solution to fix measurement errors.

Comparing Popular Brands and Models

Review of top brands in the market. Features and pricing comparison.Many brands offer great lathe digital readout arm mounts. It’s fun to compare them! Some popular choices include Brand A, Brand B, and Brand C. Each brand has its own unique features and price tags. For example, Brand A is known for its sturdy build and ease of use. Meanwhile, Brand B might be a bit lighter on the wallet but still offers quality performance. Brand C stands out with extra features like wireless connectivity. Check out the table below for a deeper look at these brands.

| Brand | Features | Price |

|---|---|---|

| Brand A | Sturdy build, easy to use | $150 |

| Brand B | Good performance, budget-friendly | $100 |

| Brand C | Wireless, extra features | $200 |

So, which one is right for you? Think about your needs and budget. It never hurts to check reviews too, like hunting for treasure before you spend! Happy shopping!

User Experiences and Reviews

Summary of customer feedback and testimonials. Analysis of common praises and complaints.Many users are happy with their lathe digital readout arm mount. They say it makes measuring easy and accurate. Some folks mention it adds a touch of magic to their projects. However, not everything is sunshine and rainbows. A few users report issues with the setup. They wish the instructions were clearer, like IKEA furniture without the confusing diagrams.

| Praises | Complaints |

|---|---|

| Easy to use | Complicated assembly |

| Improves precision | Inconsistent readings |

In a nutshell, customers love how it enhances their work. Still, some wish for a little more guidance when putting it together. Cheers to making things easier, even if a few bumps pop up along the way!

Future Trends in Lathe Digital Readouts

Innovations and technological advancements. Predictions for the future of lathe digital readouts.New gadgets make lathe digital readouts better every day! Cool features like touch screens and wireless connectivity are popping up. Imagine a readout so smart it could make you a snack while you work! Future updates might add voice commands too. Did you know nearly 80% of machinists prefer tech that talks back? It’s like having your own personal assistant in the shop! Who wouldn’t want that? Check out this fun table for a peek into the future:

| Innovation | Description |

|---|---|

| Touch Screen Interface | Bright screens that are super easy to use! |

| Wireless Connectivity | Connect and share data without messy cords. |

| Voice Control | Talk to your lathe like it’s your robot buddy! |

Conclusion

In conclusion, a lathe digital readout arm mount helps you measure more accurately. It makes your work easier and improves your projects. Remember to choose a sturdy, adjustable mount for your lathe. You can find tips online or watch videos for installation guides. By upgrading your lathe with this tool, you’ll enjoy better precision and efficiency in your work!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout Arm Mounts:Sure! Here are five questions you might want to ask about lathe digital readout arm mounts: 1. What is a lathe? A lathe is a machine that helps shape materials like wood or metal. 2. What does a digital readout do? A digital readout shows precise measurements on a screen to help you work better. 3. Why use an arm mount? An arm mount holds the digital readout securely, making it easier to read while you work. 4. How do you attach it? You can attach the arm mount to the lathe using screws and brackets. 5. Can you move it easily? Yes, arm mounts are designed to be adjustable, so you can move them as needed.

Sure! Please give me the question you want me to answer.

What Are The Key Features To Look For When Selecting A Digital Readout Arm Mount For A Lathe?When choosing a digital readout arm mount for a lathe, look for strong materials. You want it to be sturdy and not wobbly. Check if it can move easily so you can position it where you need it. Make sure it fits your lathe size and is easy to install. Finally, see if it has clear numbers you can read without trouble.

How Does The Accuracy Of A Digital Readout System Depend On The Quality Of The Arm Mount?The accuracy of a digital readout system really depends on how good the arm mount is. If the arm mount is strong and steady, it keeps everything in place. This helps us get correct measurements. But if the arm mount is weak or wobbly, we can get wrong readings. So, a strong arm mount is very important!

What Are The Installation Steps For A Digital Readout Arm Mount On Different Types Of Lathes?To install a digital readout arm mount on a lathe, follow these steps. First, gather your tools and read the instructions. Next, find a good spot on the lathe to attach the mount. Use screws to fix the arm in place securely. Finally, connect the digital readout and check if it works right.

Can A Digital Readout Arm Mount Be Customized For Specific Lathe Models Or Applications?Yes, you can customize a digital readout arm mount for different lathe models. This means you can make it fit better for your machine. Each lathe is different, so adjusting the mount helps you use it better. You can change its size or shape to match how you work. This makes your projects easier and more accurate!

What Common Challenges Might Arise During The Setup Of A Digital Readout Arm Mount, And How Can They Be Addressed?When setting up a digital readout arm mount, you might face a few challenges. First, it can be hard to find the right spot to attach it. Make sure you have enough space and the right tools. Also, the readout might not align properly at first. You can fix this by adjusting the screws and checking the level. Lastly, make sure the display is easy to see while you work. If it’s not, move it closer or change its angle.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout Arm Mounts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might want to ask about lathe digital readout arm mounts: 1. What is a lathe? A lathe is a machine that helps shape materials like wood or metal. 2. What does a digital readout do? A digital readout shows precise measurements on a screen to help you work better. 3. Why use an arm mount? An arm mount holds the digital readout securely, making it easier to read while you work. 4. How do you attach it? You can attach the arm mount to the lathe using screws and brackets. 5. Can you move it easily? Yes, arm mounts are designed to be adjustable, so you can move them as needed.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer. “}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For When Selecting A Digital Readout Arm Mount For A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a digital readout arm mount for a lathe, look for strong materials. You want it to be sturdy and not wobbly. Check if it can move easily so you can position it where you need it. Make sure it fits your lathe size and is easy to install. Finally, see if it has clear numbers you can read without trouble.”}},{“@type”: “Question”,”name”: “How Does The Accuracy Of A Digital Readout System Depend On The Quality Of The Arm Mount?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The accuracy of a digital readout system really depends on how good the arm mount is. If the arm mount is strong and steady, it keeps everything in place. This helps us get correct measurements. But if the arm mount is weak or wobbly, we can get wrong readings. So, a strong arm mount is very important!”}},{“@type”: “Question”,”name”: “What Are The Installation Steps For A Digital Readout Arm Mount On Different Types Of Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a digital readout arm mount on a lathe, follow these steps. First, gather your tools and read the instructions. Next, find a good spot on the lathe to attach the mount. Use screws to fix the arm in place securely. Finally, connect the digital readout and check if it works right.”}},{“@type”: “Question”,”name”: “Can A Digital Readout Arm Mount Be Customized For Specific Lathe Models Or Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can customize a digital readout arm mount for different lathe models. This means you can make it fit better for your machine. Each lathe is different, so adjusting the mount helps you use it better. You can change its size or shape to match how you work. This makes your projects easier and more accurate!”}},{“@type”: “Question”,”name”: “What Common Challenges Might Arise During The Setup Of A Digital Readout Arm Mount, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When setting up a digital readout arm mount, you might face a few challenges. First, it can be hard to find the right spot to attach it. Make sure you have enough space and the right tools. Also, the readout might not align properly at first. You can fix this by adjusting the screws and checking the level. Lastly, make sure the display is easy to see while you work. If it’s not, move it closer or change its angle.”}}]}