Have you ever wondered how metal parts are made with such precision? It’s fascinating! In the world of metalworking, a **lathe** is an important tool. But there’s more to it than just spinning metal. Imagine using a **digital readout** on a lathe to get exact measurements as you work. This makes the process much simpler.

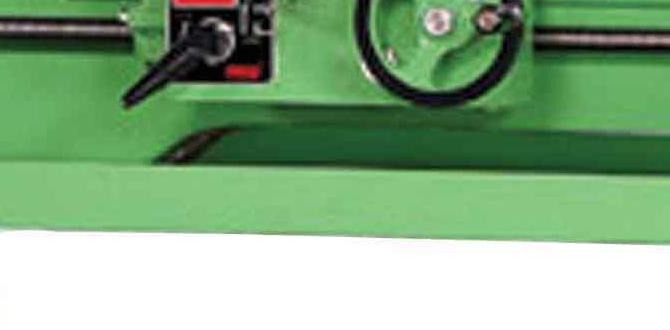

In many workshops, a good **drive system** powers the lathe. This system helps the machine run smoothly. It’s like the engine of a car. Without a great drive system, things can go wrong. Have you tried using a machine that didn’t run well? It can be frustrating!

Let’s dive deeper into how these parts work together. We’ll explore the **lathe digital readout** and its benefits. These tools change how we create metal pieces. You might be surprised at how they improve results!

Lathe Digital Readout: Enhancing Metal Lathe Drive System Efficiency

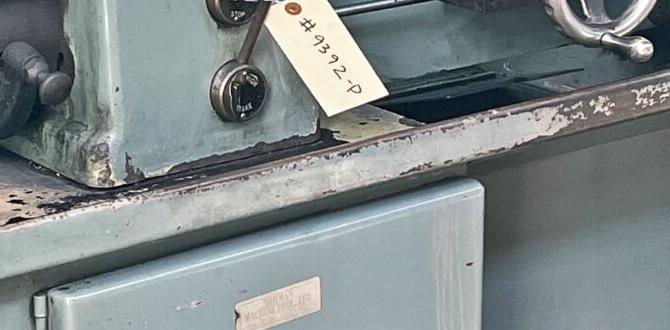

Lathe Digital Readout Metal Lathe Drive System

A lathe digital readout makes machining easier and more accurate. It shows real-time measurements while you work. This system improves precision by displaying the exact position of the cutting tool. Imagine you’re shaping a piece of metal; the readout helps you avoid mistakes. Plus, using this system often speeds up projects. Did you know that many modern lathes now come with this technology? It’s a game-changer for anyone working with metal!Understanding Lathe Digital Readout Systems

Definition and purpose of digital readouts (DRO) in machining.. Key components of a DRO system..Imagine trying to measure a long piece of metal without a ruler! A digital readout (DRO) system makes precise measurements a breeze. It displays exact positions on a screen, helping machinists work with accuracy. It’s like having a magical tape measure that never gets tangled!

Key parts of a DRO include a display unit, sensors, and encoders. The display shows the measurements, while sensors and encoders track movement. Here’s a quick look:

| Components | Function |

|---|---|

| Display Unit | Shows measurements |

| Sensors | Detect movement |

| Encoders | Convert movement into data |

In short, DROs are like having a helpful robot friend in your workshop, ready to guide you through every cut!

Benefits of Using a Digital Readout on Metal Lathes

Improved accuracy and precision in measurements.. Timesaving features and efficiency gains..Using a digital readout on metal lathes brings a whole toolbox of benefits. First, it boosts accuracy and precision in measurements. Say goodbye to guessing! A digital display shows exactly what you need. Secondly, these systems save time. Imagine cutting down your work hours while still making perfect parts. That’s a win-win! Who doesn’t want more time for snacks?

| Benefit | Description |

|---|---|

| Improved Accuracy | No more measuring mistakes. |

| Time Efficiency | Finish tasks faster and smarter. |

How to Choose the Right Digital Readout System for Your Metal Lathe

Factors to consider: size, precision, and ease of use.. Recommendations based on specific lathe models and applications..Choosing a digital readout for your metal lathe can feel like a trip to a toy store—exciting yet confusing! First, think about size. Make sure your readout fits well on your lathe. Next is precision; a high-precision readout saves you from errors and makes your projects look sharp! Finally, check for ease of use. A user-friendly display means less time scratching your head and more time creating. For example, mini lathes work great with simple models, while larger lathes may need advanced systems.

| Lathe Model | Recommended Digital Readout |

|---|---|

| Mini Lathe | Basic DRO Model |

| Standard Lathe | Mid-Range DRO |

| Heavy-Duty Lathe | Advanced DRO with High Precision |

So, think of it like finding the right shoe. It has to fit, feel good, and help you run that race to metal masterpiece! Happy lathe-ing!

Installation and Setup of a Lathe Digital Readout System

Stepbystep installation guide for a DRO on a metal lathe.. Common mistakes to avoid during installation..Installing a digital readout (DRO) on your metal lathe can greatly improve accuracy. Follow this simple step-by-step guide:

- Gather your tools and the DRO kit.

- Clean the lathe and area before starting.

- Attach the scales carefully to the lathe.

- Connect wires following the manual carefully.

- Power on the system to check functionality.

Avoid these common mistakes:

- Skipping the cleaning step.

- Ignoring the manual.

- Forgetting to test the DRO after installation.

Taking your time during setup leads to better results. Happy turning!

What is a digital readout system?

A digital readout system, or DRO, shows exact measurements on a display. It helps you make precise cuts and adjustments easier using clear numbers. This makes your projects go smoothly!

Maintenance Tips for Longevity of Digital Readout Systems

Routine maintenance practices to ensure accuracy.. Troubleshooting common issues..Taking good care of your digital readout system is key for keeping it sharp and accurate. Regularly clean the surfaces and check for loose wires. It’s like brushing your teeth—don’t skip it! For troubleshooting, if the display goes haywire, try restarting the system first. If that doesn’t work, consult the manual or call for help. Remember, a happy lathe makes for a happy workshop!

| Maintenance Tip | Action |

|---|---|

| Check Connections | Inspect wires for secure fits |

| Clean Display | Use a soft cloth to avoid scratches |

| Calibrate System | Run accuracy tests regularly |

| Restart System | Try this for funky displays |

Case Studies: Success Stories with Digital Readout Systems

Examples of businesses that improved productivity with DRO.. Metrics showcasing the impact of digital readouts on operations..Many businesses have seen great success by using digital readout systems. For instance, a local machine shop reported a 30% increase in productivity after installing a digital readout on their lathe. Another business noted a 25% reduction in errors, thanks to accurate measurements. These systems help operators measure more quickly and accurately. Here are a few key points:

- Improved speed: Faster setup times.

- Better accuracy: Less rework needed.

- Higher profits: Increased production leads to more sales.

Using digital readouts can really change how a business operates, leading to higher quality products and happier customers.

How do digital readout systems help businesses?

Digital readout systems help businesses by providing faster measurements. This leads to fewer mistakes and less time wasted. Overall, they help improve efficiency and boost profits.

Future Trends in Lathe Digital Readout Technology

Innovations shaping the future of DRO systems.. How advancements in technology could enhance metal lathe operations..New ideas are lighting up the world of digital readout (DRO) technology. Imagine *smart* DRO systems that talk to your machines! These systems could use sensors to give real-time feedback. They can help you avoid the dreaded “oops, I cut it wrong!” moment. Plus, getting more precise measurements can make your work smoother and faster. Innovation never takes a coffee break, right? Here’s a look at some cool advancements:

| Innovation | Description |

|---|---|

| Wireless Connectivity | Connects DRO to your devices for live updates. |

| AI Algorithms | Predicts issues before they happen, like a magical crystal ball. |

| Smart Displays | Interactive screens for easier reading, so no more squinting! |

Such advancements are not just fancy talk. They can lead to better efficiency in metal lathe operations and keep everyone happy with precise cuts, making “measure twice, cut once” a whole lot easier!

Conclusion

In summary, a lathe digital readout improves accuracy and convenience when using a metal lathe. This system helps you see your measurements clearly. Understanding how it works enhances your skills. We encourage you to explore more about these technologies and consider trying one out in your projects. Get started today and enjoy precision in your metalworking!FAQs

What Are The Key Features To Look For In A Digital Readout (Dro) System For A Metal Lathe?When choosing a digital readout (DRO) for a metal lathe, look for a clear display. You want to see numbers easily. Make sure it has good accuracy, so your measurements are right. A user-friendly design is also important, so you can quickly learn how to use it. Finally, check if it has enough measurement axes for your work.

How Does A Dro Improve The Precision And Efficiency Of Machining Operations On A Metal Lathe?A Digital Readout (DRO) shows us exactly where the tool is on a metal lathe. It helps you see measurements clearly. This makes it easier to make the right cuts. With a DRO, you can work faster and more accurately. Your projects come out better and with less waste.

What Are The Different Types Of Drive Systems Available For Metal Lathes, And How Do They Affect Performance?Metal lathes use different drive systems to work. The main types are belt drives, gear drives, and direct drives. Belt drives are smooth and quiet, while gear drives give more power. Direct drives are fast and simple. Each type can change how well the lathe can cut and shape metal.

Can A Digital Readout System Be Retrofitted Onto An Older Metal Lathe Model, And What Considerations Should Be Taken Into Account?Yes, you can add a digital readout system to an older metal lathe. First, you need to check if the lathe has enough space for new parts. You should also see if the old machine’s movements work well with the new system. Finally, make sure you can understand how to use the new controls properly. It can make your work much easier!

How Do The Accuracy And Resolution Of A Dro Influence The Overall Machining Process In A Lathe Setup?A Digital Readout (DRO) helps you see measurements on a lathe. Higher accuracy means you make parts that fit perfectly. Better resolution shows tiny details, so you can make small adjustments. This leads to smoother and better-looking finished pieces. So, a good DRO makes your work easier and more exact!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Digital Readout (Dro) System For A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a digital readout (DRO) for a metal lathe, look for a clear display. You want to see numbers easily. Make sure it has good accuracy, so your measurements are right. A user-friendly design is also important, so you can quickly learn how to use it. Finally, check if it has enough measurement axes for your work.”}},{“@type”: “Question”,”name”: “How Does A Dro Improve The Precision And Efficiency Of Machining Operations On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A Digital Readout (DRO) shows us exactly where the tool is on a metal lathe. It helps you see measurements clearly. This makes it easier to make the right cuts. With a DRO, you can work faster and more accurately. Your projects come out better and with less waste.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Drive Systems Available For Metal Lathes, And How Do They Affect Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use different drive systems to work. The main types are belt drives, gear drives, and direct drives. Belt drives are smooth and quiet, while gear drives give more power. Direct drives are fast and simple. Each type can change how well the lathe can cut and shape metal.”}},{“@type”: “Question”,”name”: “Can A Digital Readout System Be Retrofitted Onto An Older Metal Lathe Model, And What Considerations Should Be Taken Into Account? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can add a digital readout system to an older metal lathe. First, you need to check if the lathe has enough space for new parts. You should also see if the old machine’s movements work well with the new system. Finally, make sure you can understand how to use the new controls properly. It can make your work much easier!”}},{“@type”: “Question”,”name”: “How Do The Accuracy And Resolution Of A Dro Influence The Overall Machining Process In A Lathe Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A Digital Readout (DRO) helps you see measurements on a lathe. Higher accuracy means you make parts that fit perfectly. Better resolution shows tiny details, so you can make small adjustments. This leads to smoother and better-looking finished pieces. So, a good DRO makes your work easier and more exact!”}}]}