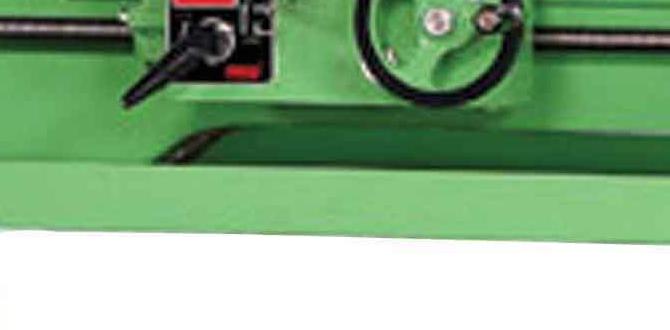

Have you ever watched a metal lathe in action? It’s like a dance of precision and skill. In the world of machining, a lathe plays a big role. But what makes it even better? A modern touch with a lathe digital readout! This handy tool shows exact measurements right on the screen.

Imagine trying to thread a bolt without knowing the right size. It can be frustrating, right? The threading dial on a lathe helps you avoid those mistakes. It guides you to perfect measurements. With these tools, metalworking becomes easier and more accurate.

Did you know that even small adjustments can lead to big changes? A simple turn of the threading dial can make all the difference. This is why many machinists love their digital readouts. They help create beautiful, precise parts with ease.

Ready to dive deeper into the world of metal lathes? Join us as we explore how these devices transform the way we work with metal!

Lathe Digital Readout: Enhance Metal Lathe Threading Dial Accuracy

Discovering the Lathe Digital Readout for Metal Lathe Threading

Have you ever wondered how precise metal lathes work? The lathe digital readout (DRO) for metal lathe threading is key for accuracy. This gadget shows exact measurements, so you don’t have to guess. Imagine saving time while creating the perfect thread! It makes difficult tasks easier, turning complex projects into simple steps. With a reliable threading dial, you can achieve professional-level results at home. Isn’t it exciting to think about what you could create?Understanding Lathe Digital Readouts

Definition and purpose of digital readouts in machining. Types of digital readouts available for lathes.Digital readouts are handy tools in machining. They show you precise measurements, making it easier to get the job done right. Imagine trying to cut metal with a ruler from the kitchen—yikes! There are different types of digital readouts for lathes, each with unique features. Some are simple, while others come with fancy buttons that will make you feel like a tech wizard. Here’s a quick look:

| Type | Features |

|---|---|

| Basic Readout | Simple display for length and diameter |

| Advanced Readout | Includes threading capabilities and storage |

| Smart Readout | Connects to apps for even more control! |

Having a digital readout can turn a daunting task into a breeze. So, next time you’re in the workshop, you’ll be ready to make some magic happen!

Benefits of Using a Digital Readout on Metal Lathes

Improved precision and accuracy in measurements. Enhanced efficiency and speed in production processes.Using a digital readout on metal lathes has some fantastic benefits. First, it greatly improves precision and accuracy in measurements. No more guesswork! You can now measure parts with the accuracy of a hawk spotting its lunch. Second, it boosts efficiency and speed in production processes. Imagine this: you get your work done faster than a cheetah chasing its dinner! The combination of these benefits means you spend less time fiddling with dials and more time creating awesome stuff!

| Advantage | Benefit |

|---|---|

| Precision | Accurate measurements lead to better quality work. |

| Speed | Quicker processes mean more time for fun! |

Choosing the Right Digital Readout for Your Metal Lathe

Key features to consider (e.g., display type, measurement units). Compatibility with different lathe models.Choosing the right digital readout can improve your metal lathe work. Look for these key features:

- Display type: Choose a clear, easy-to-read screen.

- Measurement units: Make sure it shows inches and millimeters.

Compatibility matters too. Check if the readout fits your specific lathe model. Some readouts work with many brands, while others are model-specific. Knowing this helps you pick the right one, making your work smoother and more precise.

What should I consider when buying a digital readout?

Consider display clarity, measurement options, and lathe model compatibility. These details will help you make better cuts and measurements.

Installation Process for Digital Readouts on Metal Lathes

Stepbystep guide on how to install a digital readout. Common challenges and how to troubleshoot them.Installing a digital readout on a metal lathe can seem tricky, but it’s doable. Follow this simple guide for a smooth process:

- Start by gathering all tools and materials you need.

- Carefully read the digital readout manual.

- Mount the display unit in a visible spot.

- Connect the sensors to the lathe.

- Double-check all connections are secure.

- Finally, turn on the machine and test the readout.

Sometimes, issues pop up. If the display doesn’t light up:

- Check the power source.

- Make sure all wires are plugged in.

- Look for any loose connections.

With patience, you’ll have it up and running!

What are common problems during installation?

Common problems include loose wires, incorrect setup, or power issues. Always check the connections if you face trouble. With careful troubleshooting, most problems can be solved easily.

Calibration and Maintenance of Digital Readouts

Importance of regular calibration for accuracy. Maintenance tips to extend the lifespan of the readout.Regular calibration is important for keeping your digital readout precise. Think of it like tuning a guitar. If not calibrated, a readout can make your measurements feel like a game of darts—lots of misses! To keep it running smoothly, clean the screen often and keep it away from moisture. Check batteries regularly because nothing is worse than a flat battery at the wrong time.

| Maintenance Tips | Effects |

|---|---|

| Clean the display | Clear readings |

| Store in a dry place | Longer lifespan |

| Regular battery checks | Avoid surprises |

With these habits, your lathe’s digital readout will be as happy as a clam! Remember, a little care goes a long way!

Common Issues and Solutions when Using Digital Readouts

Troubleshooting common problems (e.g., display errors, measurement discrepancies). Best practices for optimizing performance.Using digital readouts can sometimes feel like wrestling with a badger. First, you might see display errors that make numbers jump around like they’re doing the cha-cha. If this happens, check your connections. Loose wires can be sneakier than a raccoon in a trash can! For measurement problems, ensure the tool is calibrated correctly. Did you know that 80% of users find issues stem from simple mishaps? So, double-check your settings.

| Common Issues | Solutions |

|---|---|

| Display Errors | Check connections and reset the device. |

| Measurement Discrepancies | Calibrate the tool properly. |

To keep your digital readout running smoothly, always follow the user manual. Clean the device regularly too—dust bunnies love hiding in the corners! With a little care, your lathe can be as reliable as your favorite pair of socks.

Real-World Applications of Lathe Digital Readouts

Examples of industries utilizing digital readouts in metal lathing. Case studies demonstrating enhanced productivity and quality.Many industries use lathe digital readouts to improve their work. For example, automotive shops rely on these tools for precise measurements. In aerospace, accuracy is key for safety. Manufacturing plants are also adopting them to increase speed and reduce waste. Here are some key benefits:

- Increased accuracy leads to better quality.

- Faster production times save money.

- Less material waste reduces costs.

How do digital readouts improve productivity?

Digital readouts help workers measure quickly and correctly. That means they can make more parts in less time. Many companies report a 20% increase in productivity after using these tools.

Comparative Analysis: Digital Readout vs. Manual Measurements

Pros and cons of using digital readouts versus traditional methods. Costbenefit analysis for businesses.Using digital readouts or manual measurements for lathes has pros and cons. Digital readouts are precise and easy to read. This saves time and reduces mistakes. However, they can be costly. Manual methods are cheaper and teach skills but take longer and may lead to errors.

- Digital Readouts: Quick, accurate, but expensive

- Manual Measurements: Cost-effective, educational, but slow and prone to error

For businesses, choosing the right method can affect profits. A study shows that 70% of shops prefer digital for efficiency. But firms must balance costs with benefits.

Which method is better for beginners?

Manual measurements help newbies learn important skills, while digital readouts make work quicker. Starting with manuals can build confidence.

Future Trends in Digital Readout Technology for Lathes

Innovations on the horizon (e.g., smart technology integration). Predictions for the impact of emerging trends on the machining industry.New technology is changing how we use lathes. Smart technology is on the horizon. This will make machines easier and quicker to use. For example, machines may connect to the internet. This can help monitor their performance remotely. Here are some predictions:

- Increased precision in measurements.

- Faster adjustments for threading.

- Better user interfaces for all skill levels.

- Cost reduction through automation.

- Integration with other smart factory tools.

Experts predict that these advancements will boost safety and productivity in the machining industry. Imagine a lathe that talks to you! This could help you make the right cuts every time.

How will smart technology improve lathes?

Smart technology will enhance precision and usability. It allows quicker adjustments and real-time performance tracking, making it easier for users to achieve accurate results.

Conclusion

In conclusion, a digital readout on a metal lathe makes threading easier and more precise. It helps you see measurements clearly and saves time. With practice, you can improve your skills and create better projects. Don’t hesitate to explore more about lathe operations and features. Start using a digital readout, and watch your confidence grow!FAQs

How Does A Digital Readout System Enhance The Precision Of Threading Operations On A Metal Lathe?A digital readout system shows numbers on a screen. This helps you see exactly how much you are moving the tool. With clear readings, you can make better adjustments. It makes threading, or creating grooves, more accurate. That means your metal pieces fit together better!

What Are The Key Features To Look For In A Digital Readout For Metal Lathe Threading Applications?When choosing a digital readout for threading on a metal lathe, look for clear numbers you can easily see. It should have a simple setup so you can use it right away. Make sure it shows measurements in both inches and millimeters, so you can use what you like. A good readout will help you keep track of your cuts and avoid mistakes. Lastly, it should be durable and able to handle some bumps in the workshop.

How Do You Properly Calibrate A Lathe Digital Readout To Ensure Accurate Measurements During Threading?To calibrate a lathe digital readout, first, make sure the machine is turned off. Next, use a standard measuring tool, like a caliper, to measure your workpiece. Turn on the lathe and enter the exact measurement into the digital readout. Check if the readout matches your tool’s measurement. Repeat this until the numbers match perfectly for accurate threading.

Can A Digital Readout Be Used For Both Imperial And Metric Threading On A Metal Lathe, And If So, How?Yes, you can use a digital readout for both imperial and metric threading on a metal lathe. This tool shows measurements clearly, helping you track how much you’re cutting. You just need to switch the settings between imperial (like inches) and metric (like millimeters) when working. Many digital readouts have a button to change between these systems easily. This way, you can work with both types of threading without any trouble!

What Common Issues Might Arise When Using A Digital Readout For Threading, And How Can They Be Resolved?When using a digital readout for threading, you might see wrong measurements or it could freeze up. This can happen if the tool isn’t set properly. To fix this, make sure you check the settings before you start. If it freezes, you can try turning it off and back on. Always keep the machine clean to avoid problems!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “How Does A Digital Readout System Enhance The Precision Of Threading Operations On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital readout system shows numbers on a screen. This helps you see exactly how much you are moving the tool. With clear readings, you can make better adjustments. It makes threading, or creating grooves, more accurate. That means your metal pieces fit together better!”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Digital Readout For Metal Lathe Threading Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a digital readout for threading on a metal lathe, look for clear numbers you can easily see. It should have a simple setup so you can use it right away. Make sure it shows measurements in both inches and millimeters, so you can use what you like. A good readout will help you keep track of your cuts and avoid mistakes. Lastly, it should be durable and able to handle some bumps in the workshop.”}},{“@type”: “Question”,”name”: “How Do You Properly Calibrate A Lathe Digital Readout To Ensure Accurate Measurements During Threading? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate a lathe digital readout, first, make sure the machine is turned off. Next, use a standard measuring tool, like a caliper, to measure your workpiece. Turn on the lathe and enter the exact measurement into the digital readout. Check if the readout matches your tool’s measurement. Repeat this until the numbers match perfectly for accurate threading.”}},{“@type”: “Question”,”name”: “Can A Digital Readout Be Used For Both Imperial And Metric Threading On A Metal Lathe, And If So, How? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can use a digital readout for both imperial and metric threading on a metal lathe. This tool shows measurements clearly, helping you track how much you’re cutting. You just need to switch the settings between imperial (like inches) and metric (like millimeters) when working. Many digital readouts have a button to change between these systems easily. This way, you can work with both types of threading without any trouble!”}},{“@type”: “Question”,”name”: “What Common Issues Might Arise When Using A Digital Readout For Threading, And How Can They Be Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a digital readout for threading, you might see wrong measurements or it could freeze up. This can happen if the tool isn’t set properly. To fix this, make sure you check the settings before you start. If it freezes, you can try turning it off and back on. Always keep the machine clean to avoid problems!”}}]}