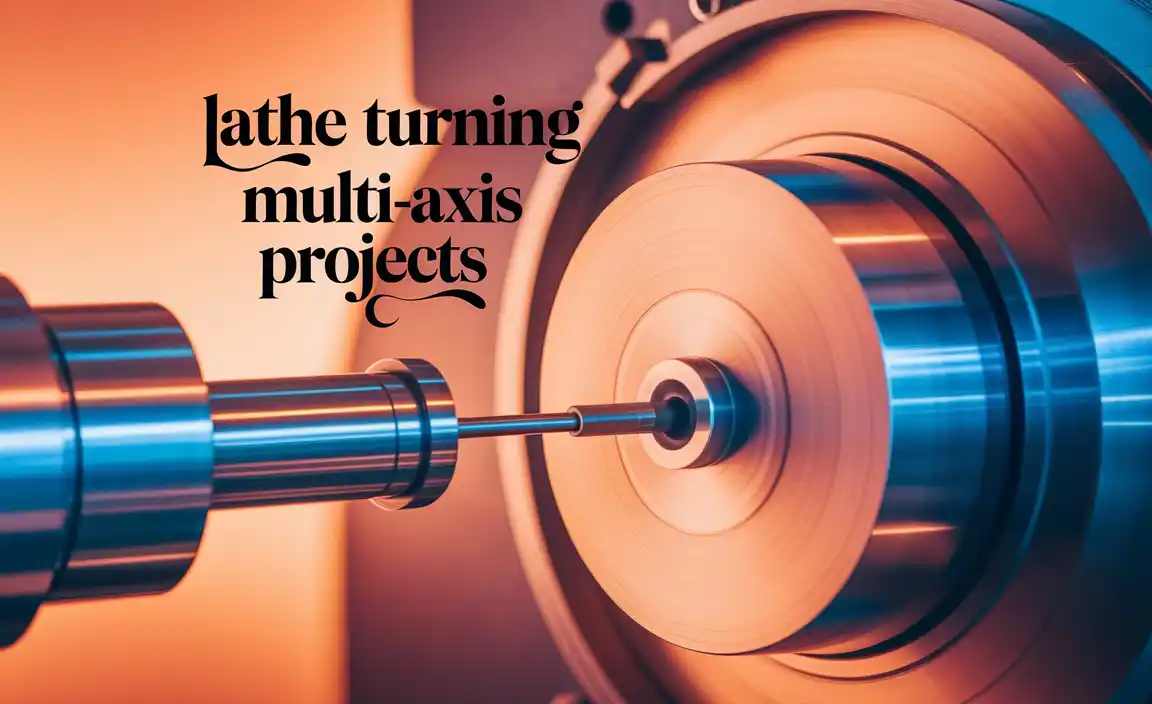

Have you ever wondered how craftsmen create smooth, round shapes from wood or metal? The key to this magic often lies in something called lathe faceplate turning. This technique lets you shape materials into beautiful pieces. It’s like turning a simple block into a stunning bowl or an intricate decorative item.

Lathe faceplate turning is not just for experts. Anyone can learn! Imagine taking a plain piece of wood and by using a lathe, transforming it into something unique. It’s exciting to think of what you can create!

Did you know that the lathe is one of the oldest machines still in use today? It has been around for thousands of years! This shows how much people value the art of turning. Whether you are a beginner or have some experience, understanding the basics of lathe faceplate turning can open up a world of creativity.

In this article, we will dive into the essential techniques and tips. You’ll discover how to use a lathe faceplate safely and effectively. Let’s unlock the artist within you and start turning!

Lathe Faceplate Turning Basics: A Comprehensive Guide

Lathe Faceplate Turning Basics

Faceplate turning on a lathe is a fun yet essential skill for woodworkers. It allows you to create unique shapes, like bowls or vases, easily. You learn how to securely attach workpieces for safe turning. Are you wondering how to start shaping wood with a lathe? Proper tool usage is key for good results. Did you know that faceplate turning dates back centuries? This technique gives wood a beautiful and smooth finish, making each project special.Understanding Lathe Faceplates

Definition and purpose of faceplates. Types of faceplates available in the market.A lathe faceplate is a tool used in woodworking and metalworking. It holds your workpiece securely while turning it. This helps shape the material evenly. Faceplates are important for creating smooth, round objects. They come in various types, including:

- Standard faceplates – Basic models for general use.

- Adjustable faceplates – Allow for different sizes.

- Specialty faceplates – Designed for specific tasks or shapes.

Choosing the right type of faceplate makes your project easier and safer.

What does a lathe faceplate do?

It holds the workpiece in place while shaping materials on the lathe. This helps create smooth surfaces and precise shapes.

Setting Up Your Lathe for Faceplate Turning

Stepbystep guide to securely mount a faceplate. Importance of checking lathe alignment and calibration.Getting ready to turn your lathe into a faceplate powerhouse is like prepping for a big birthday party. First, make sure you securely mount the faceplate. Tighten the screws until they’re snug, but don’t overdo it—no need for Hulk strength! Next, check your lathe’s alignment. A crooked lathe will ruin your masterpiece. It’s like trying to draw a straight line with a wobbly ruler!

| Step | Action |

|---|---|

| 1 | Attach the faceplate to the workpiece. |

| 2 | Tighten screws securely. |

| 3 | Check lathe alignment. |

| 4 | Calibrate if necessary. |

By following these steps, you’ll have a setup that’s ready for action. Remember, a well-aligned lathe is key to smooth turning. So don’t skip the checks! A great faceplate setup equals great results.

Essential Tools and Equipment for Faceplate Turning

List of necessary tools: chisels, gouges, and more. Recommended safety gear for faceplate turning.Starting faceplate turning? You’ll need some trusty tools! Essential items include chisels for carving, gouges for detailed work, and a few others for added flair. Safety first! Always wear protective goggles to keep those tiny wood chips from becoming surprise projectiles. A dust mask helps too, especially if you want to breathe without tasting sawdust! Check out the table below for a quick look at what you’ll need:

| Tool | Purpose |

|---|---|

| Chisels | For carving and shaping |

| Gouges | For making detailed cuts |

| Safety Goggles | To protect your eyes |

| Dust Mask | To keep your lungs happy |

Basic Techniques for Turning with a Faceplate

How to start the turning process effectively. Techniques to achieve a smooth finish.Starting with a faceplate can feel like a circus act—one wrong move and it could all go wrong! First, make sure your lathe is secure, and your faceplate is tightly fastened. Then, engage your wood piece gently; think of it as a dance, not a wrestling match. Breathe steady and let the tool do the work. To get a smooth finish, keep your tools sharp. A sharp chisel is like a magician’s wand—it creates magic with ease! Keep your speed steady, and watch the shavings fly, ensuring they don’t become a hazard.

| Technique | Tip |

|---|---|

| Secure your setup | Check tightness regularly |

| Keep your tools sharp | A sharp tool makes the job fun! |

| Control your speed | Find your rhythm! |

Common Challenges in Faceplate Turning

Identifying and addressing vibration issues. Solutions for uneven turning and tool control.Faceplate turning can be tricky. Vibration issues often mess up the smoothness of your work. This can happen due to an unbalanced piece. Make sure your workpiece is centered securely. This helps reduce vibration. Uneven turning can make your project look bad. Use sharp tools, and keep your lathe properly maintained for better control.

- Check the chuck tightness.

- Balance the workpiece well.

- Use heavier materials for stability.

Good tool control can make all the difference. Always remember, practice helps you improve!

How do I fix vibration while turning?

You can fix vibration by ensuring your workpiece is balanced and securely attached. This is important for smooth cuts and a great finish.

What can I do about uneven turning?

To solve uneven turning issues, use sharp tools and steady hands. Regular maintenance of your lathe also helps keep everything on track.

Maintaining Your Lathe and Faceplate

Routine maintenance tips for longevity. How to clean and store your faceplates properly.Keeping your lathe and faceplate in top shape is like giving them a spa day! Regular maintenance helps them last longer. First, check the belts and oil the moving parts. Clean your faceplates with a soft cloth after each use to keep them shiny. Store them in a dry place. Want to protect your faceplates from rust? Try wrapping them in a clean, dry cloth! Here’s a quick routine for you:

| Task | Frequency |

|---|---|

| Check belts | Weekly |

| Clean faceplates | After each use |

| Oil moving parts | Monthly |

| Store in a dry place | Always |

With these tips, you can keep your lathe and faceplate working like a dream. Remember, a well-cared lathe is a happy lathe!

Conclusion

In summary, lathe faceplate turning is an important skill for shaping materials. You learn to mount workpieces securely and use various tools safely. Practicing these basics helps you create beautiful projects. So, grab your lathe and start experimenting! For more detailed techniques and tips, check out beginner crafting guides or video tutorials. Happy turning!FAQs

What Is A Lathe Faceplate And What Is Its Primary Purpose In Turning Operations?A lathe faceplate is a round metal plate. You attach it to a lathe, which is a machine that spins things. The faceplate holds your material, like wood, so you can shape it. Its main purpose is to keep the material steady while you work on it. This helps you create smooth and neat pieces.

How Do You Properly Mount A Workpiece Onto A Lathe Faceplate For Effective Turning?To mount a workpiece on a lathe faceplate, first, make sure the faceplate is clean. Next, place your workpiece in the center of the plate. Use screws to secure the workpiece firmly in place. Tighten the screws evenly so it won’t wobble. Lastly, check that everything is secure before you start turning!

What Safety Precautions Should Be Taken When Using A Lathe Faceplate For Turning?When using a lathe faceplate, you should always wear safety glasses to protect your eyes. Make sure to tie back long hair and avoid loose clothes. Keep your hands away from the spinning part. We should also check that the lathe is working properly before starting. Finally, always have a clear workspace and keep others at a safe distance.

What Are The Differences Between Faceplate Turning And Using A Chuck For Mounting Workpieces?When you use a faceplate to hold a piece, it’s flat and lets you attach big shapes easily. This helps you shape large wood or metal parts. A chuck, on the other hand, holds smaller objects tightly in the center with pins that grip them. Both methods help you work on materials, but they’re best for different types of pieces.

How Can You Achieve A Smooth Finish On A Workpiece When Using A Lathe Faceplate?To get a smooth finish on a workpiece with a lathe faceplate, start by using sharp tools. Keep your hands steady and the tool moving evenly. You can sand the surface gently to make it smoother. Finally, clean the workpiece to remove dust and chips. This will help you see how shiny and nice it looks!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is A Lathe Faceplate And What Is Its Primary Purpose In Turning Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe faceplate is a round metal plate. You attach it to a lathe, which is a machine that spins things. The faceplate holds your material, like wood, so you can shape it. Its main purpose is to keep the material steady while you work on it. This helps you create smooth and neat pieces.”}},{“@type”: “Question”,”name”: “How Do You Properly Mount A Workpiece Onto A Lathe Faceplate For Effective Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To mount a workpiece on a lathe faceplate, first, make sure the faceplate is clean. Next, place your workpiece in the center of the plate. Use screws to secure the workpiece firmly in place. Tighten the screws evenly so it won’t wobble. Lastly, check that everything is secure before you start turning!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Lathe Faceplate For Turning?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a lathe faceplate, you should always wear safety glasses to protect your eyes. Make sure to tie back long hair and avoid loose clothes. Keep your hands away from the spinning part. We should also check that the lathe is working properly before starting. Finally, always have a clear workspace and keep others at a safe distance.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Faceplate Turning And Using A Chuck For Mounting Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a faceplate to hold a piece, it’s flat and lets you attach big shapes easily. This helps you shape large wood or metal parts. A chuck, on the other hand, holds smaller objects tightly in the center with pins that grip them. Both methods help you work on materials, but they’re best for different types of pieces.”}},{“@type”: “Question”,”name”: “How Can You Achieve A Smooth Finish On A Workpiece When Using A Lathe Faceplate?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a smooth finish on a workpiece with a lathe faceplate, start by using sharp tools. Keep your hands steady and the tool moving evenly. You can sand the surface gently to make it smoother. Finally, clean the workpiece to remove dust and chips. This will help you see how shiny and nice it looks!”}}]}