Have you ever wondered how metal parts are shaped and created? One important tool in this process is a lathe, especially a floor mount metal lathe. This powerful machine works wonders when it comes to crafting metal. But what exactly makes it so special?

Let’s talk about the lathe chuck, a key part of this setup. The chuck holds the metal piece securely while the lathe spins it. Without a good chuck, your projects could get messy! Imagine trying to carve a statue from stone, but the stone keeps slipping away. That’s what it feels like without a reliable lathe chuck.

Did you know that the right floor mount metal lathe chuck can improve your work a lot? It can help you create precise shapes that look amazing! Many hobbyists and professionals rely on it every day. Wouldn’t you like to create something wonderful with a lathe?

In this article, we’ll explore the amazing world of lathe floor mount metal lathe chucks. You will learn how they work and why they are so useful. Get ready to dive into the world of metalworking!

Lathe Floor Mount Metal Lathe Chuck: A Comprehensive Guide

Lathe Floor Mount Metal Lathe Chuck

Discover the world of lathe floor mount metal lathe chucks! These tools hold metal pieces securely while spinning them. Have you ever wondered how machines cut metal so precisely? The chuck makes this possible! It comes in different sizes to fit various lathes, ensuring versatility for users. A fun fact: the jaw design allows for easy adjustment. With the right chuck, metalworking becomes smoother and more efficient. Dive in and explore how a lathe chuck can elevate your projects!What is a Floor Mount Metal Lathe Chuck?

Definition and purpose of floor mount metal lathe chucks. Comparison with other types of lathe chucks.A floor mount metal lathe chuck is a handy tool that holds material steady while you shape it. Think of it like a super strong hug for your metal! Its main job is to keep everything in place, so you can work safely and accurately. Compared to other chucks, like the ones that attach to a bench top, floor mount chucks are often larger and more stable. Here’s a quick look:

| Type of Chuck | Stability | Size |

|---|---|---|

| Floor Mount Chuck | High | Large |

| Bench Top Chuck | Medium | Small |

So, if you want a solid buddy for your metalwork, the floor mount metal lathe chuck is definitely worth considering!

Choosing the Right Floor Mount Metal Lathe Chuck

Key factors to consider: size, material, and application. Tips for matching lathe chuck with specific projects.Choosing a floor mount metal lathe chuck is important. Start by looking at these key factors:

- Size: Make sure the chuck matches your lathe.

- Material: Consider metal or plastic based on your projects.

- Application: Think about what you will be working on.

For matching your lathe chuck to specific tasks, think about:

- The weight of your workpiece.

- The type of projects you do most often.

Keep these factors in mind for better results and smoother work. Choosing the right chuck will help you do great projects!

What should I consider when selecting a lathe chuck?

Focus on size, material, and application. Size should fit your lathe. Material affects strength and usability. The application determines which features you need for your projects.

Installation Process for Floor Mount Metal Lathe Chucks

Stepbystep guide to installation. Common mistakes to avoid during installation.Installing a floor mount metal lathe chuck? It’s easier than you think! Follow these steps and you’ll be good to go. First, make sure your workspace is clean. Every classic mistake starts with lost tools! Next, securely attach the chuck to the lathe. Watch out for any loose screws—they can turn into *really* loud surprises. Then, calibrate it properly to ensure smooth operation. To sum it up, avoid rushing, and double-check your work. Trust me, getting a chuck in line is way cheaper than a trip to the repair shop!

| Step | Key Point |

|---|---|

| 1 | Keep workspace clean. |

| 2 | Attach chuck securely. |

| 3 | Calibrate carefully. |

| 4 | Double-check everything! |

Common errors include forgetting to tighten screws and skipping calibration. Remember: It’s way more fun to use your lathe than fix it later!

Maintenance Tips for Longevity of Your Chuck

Regular maintenance tasks and their importance. Troubleshooting common issues with metal lathe chucks.Taking care of your chuck helps it work well for a long time. Regular maintenance is key. Clean it often to remove dirt and metal shavings. Check the jaws for wear and replace them if needed. Proper lubrication keeps everything running smoothly. Ignoring these tasks can cause bigger problems down the road. If your chuck does not grip properly or feels loose, it may need adjustment. Regular checks help catch issues early.

How can I troubleshoot my lathe chuck?

To fix common problems, check these points:

- Ensure the jaws are tight and not worn.

- Look for chips or dirt that may block movement.

- Make sure the chuck is properly aligned.

If problems persist, consult your manual or seek help from a professional.

Applications of Floor Mount Metal Lathe Chucks

Industries and projects that commonly use floor mount chucks. Examples of specific tasks suited for these chucks.Many industries rely on floor mount metal lathe chucks for various tasks. These chucks are strong and stable, making them perfect for heavy-duty work. You can find them in places like:

- Manufacturing

- Aerospace

- Automotive

- Woodworking

They handle tasks like shaping metal parts, creating precision tools, and building vehicle frames. Using these chucks ensures high quality and safety in projects.

What tasks are suited for floor mount metal lathe chucks?

Specific tasks include:

- Turning metal pieces

- Drilling holes accurately

- Cutting complex shapes

Floor mount chucks help achieve precise results. They improve productivity and reduce errors.

Advanced Techniques for Metal Lathe Chuck Usage

Tips for achieving precision and accuracy. Techniques for enhancing efficiency in operations.To use a lathe effectively, focus on precision and speed. Start by checking your setup. Make sure everything aligns well. Use sharp tools for smooth cuts. This helps you create accurate shapes easily.

- Measure twice: Always double-check your measurements before cutting.

- Speed control: Adjust the lathe speed according to the material.

- Regular maintenance: Keep your tools clean and sharp for better performance.

Following these tips will improve your results. Soon, you will notice better quality in your work!

What are some tips for using a metal lathe chuck?

Use sharp tools and steady hands. Check your measurements twice to avoid mistakes. Keep your workspace tidy to boost your efficiency.

Frequently Asked Questions (FAQs) about Metal Lathe Chucks

Answers to common questions and concerns. Clarification of myths and misconceptions.People often wonder about metal lathe chucks and have some common questions. First, many think chucks are just for holding pieces. However, they also ensure precision during work! Some believe all chucks are the same, but they vary by size and type. Curious about maintenance? Regular cleaning keeps them spinning like a top! Lastly, some might fear breakage, but with good handling, they last a long time. Remember, a chuck in good shape is a lathe’s best friend!

| Question | Answer |

|---|---|

| What is a metal lathe chuck? | A device that grips the material being worked on. |

| How do I maintain my chuck? | Regular cleaning and lubrication. |

| Are all chucks the same? | No, they come in different sizes and types. |

Conclusion

In summary, a lathe floor mount metal lathe chuck is essential for precision work. It helps secure materials firmly while you cut and shape them. Choosing the right chuck makes your projects easier and safer. We encourage you to explore different types and practices. Understanding these tools will enhance your skills and boost your confidence in metalworking. Happy crafting!FAQs

What Are The Key Features To Consider When Selecting A Floor-Mounted Metal Lathe Chuck?When choosing a floor-mounted metal lathe chuck, you should think about size, grip strength, and material. The size needs to match your lathe. Good grip strength helps hold your workpiece tightly. Also, choose a chuck made from strong materials for durability. Finally, check how easy it is to use and change the chuck for different jobs.

How Does The Size And Weight Of A Lathe Affect The Stability And Performance Of A Floor-Mounted Chuck?The size and weight of a lathe help it stay steady while working. A heavier lathe doesn’t move as easily, making it safer. If the lathe is too light, it might shake when you use it. When a lathe is stable, the floor-mounted chuck works better, giving you smoother cuts. So, a good size and weight help the lathe do its job well.

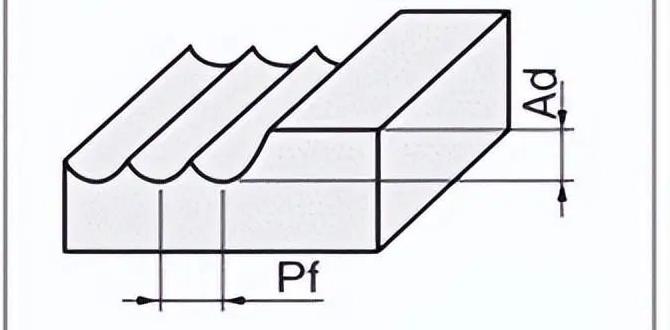

What Are The Different Types Of Chucks Available For Floor-Mounted Metal Lathes, And What Are Their Specific Applications?There are three main types of chucks for floor-mounted metal lathes: scroll chucks, faceplate chucks, and collet chucks. Scroll chucks have three or four jaws that grip items tightly. They are great for holding round or irregular shapes. Faceplate chucks attach directly to the machine and hold large items. Collet chucks use a sleeve to hold tiny pieces securely. They are best for small, precise work.

How Can Proper Maintenance Of A Floor-Mounted Metal Lathe Chuck Enhance Accuracy And Extend Its Lifespan?Keeping a floor-mounted metal lathe chuck clean helps it work better. If we check for damage regularly, the chuck can hold pieces tighter. This means our work will be more accurate. Proper care also stops rust, which can make the chuck break or wear out faster. Overall, taking care of the chuck makes it last longer and helps us make better things!

What Safety Precautions Should Be Observed When Operating A Floor-Mounted Metal Lathe With A Chuck?When using a metal lathe with a chuck, always wear safety goggles to protect your eyes. Tie back long hair and remove loose clothing to keep safe. Keep your hands clear of the moving parts. Make sure the area is tidy and free of obstacles. Always follow the instructions to avoid accidents.