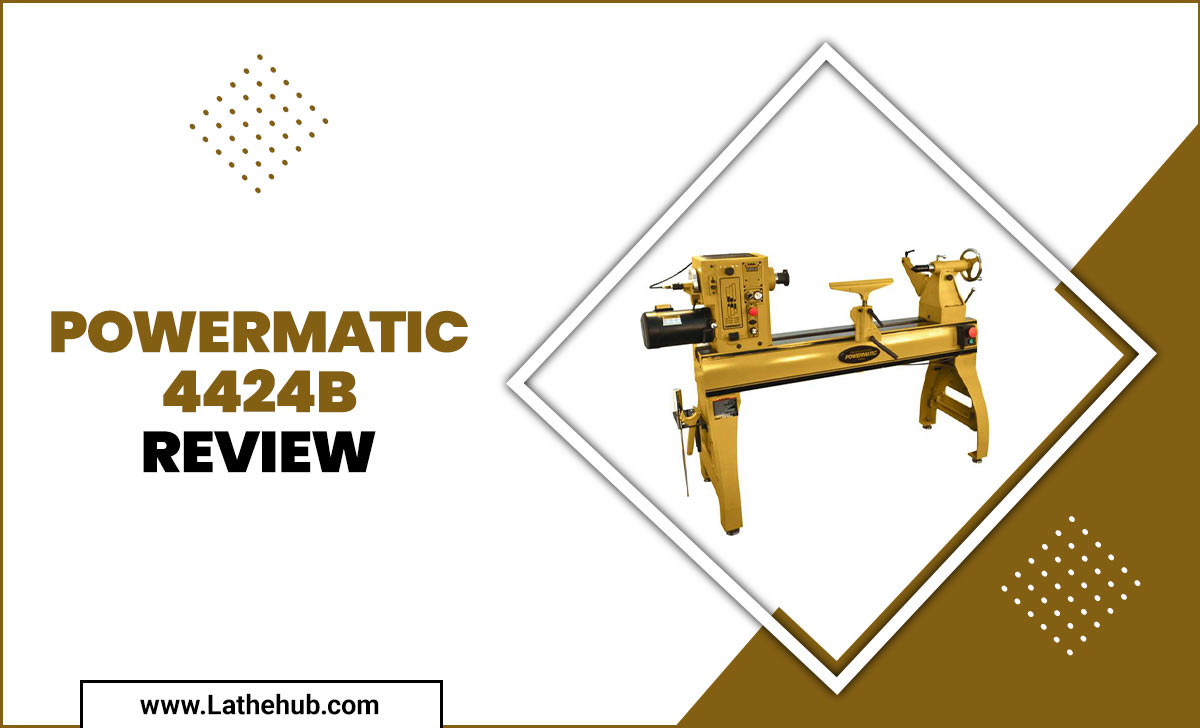

If you love creating things with your hands, you might have heard of a lathe. A lathe is a tool that helps you shape materials like metal and wood. It spins the material while you cut, sand, or drill it into shape. Have you ever thought about turning a traditional lathe into something more high-tech? This is where the lathe floor mount metal lathe CNC retrofit comes into play.

Imagine turning your regular lathe into a computer-controlled machine! That means you can make precise cuts and designs without much effort. It’s like giving your old lathe a superhero upgrade. Many makers and hobbyists find this option exciting. They love the idea of mixing old tools with modern technology.

Did you know that retrofitting a lathe can be an exciting project? You get to learn a lot while making your own upgrades. Plus, it can save you money compared to buying a new CNC machine. Whether you are a beginner or an expert, converting your lathe is an adventure worth exploring!

Lathe Floor Mount Metal Lathe Cnc Retrofit Solutions

Lathe Floor Mount Metal Lathe CNC Retrofit

Explore the exciting world of lathe floor mount metal lathe CNC retrofits! These upgrades transform your traditional lathe into a powerful CNC machine. Imagine cutting and shaping metal projects with precision and ease. Retrofits make this possible by adding cutting-edge technology. They improve accuracy and save time. Did you know that upgrading can turn a simple lathe into a production powerhouse? This can lead to better results in your metalworking endeavors!Understanding Floor Mount Metal Lathes

Definition and features of floor mount metal lathes. Advantages of using floor mount designs over other types.Floor mount metal lathes are machines used to shape metal. They sit on the floor, making them stable and easy to operate. Some of their key features include:

- Strong base for better support

- Simple design for ease of use

- Good precision for cutting metal

Using a floor mount design has advantages over other types:

- More stability prevents vibration

- Often easier to load and unload materials

- Takes up less space than larger machines

Overall, floor mount metal lathes are a great choice for anyone who works with metal.

What are the benefits of floor mount metal lathes?

Floor mount metal lathes offer improved stability, easier material handling, and efficient use of space. Their sturdy base is perfect for precise work and enhances safety during operation.

What is CNC Retrofit?

Explanation of CNC retrofitting in the context of lathes. Benefits of converting a traditional lathe to CNC.CNC retrofitting is like giving your old lathe a shiny new cape! It means upgrading a traditional lathe to a Computer Numerical Control (CNC) machine. This transformation allows the lathe to run automatically, which makes it easier to use. Imagine not having to turn those knobs all day! The benefits include better precision, faster production, and less tiredness for your arms. It’s like turning your bicycle into a motorcycle—more fun and less pedaling!

| Benefit | Description |

|---|---|

| Precision | Makes cuts accurate to the tiniest detail. |

| Speed | Speeds up the whole process of making parts. |

| Less Work | Allows you to relax and enjoy your creation! |

Key Components of a CNC Retrofit Kit

Essential parts included in a typical retrofit kit. Importance of quality components for precision and longevity.Retrofitting your lathe with a CNC kit can be exciting. A typical retrofit kit includes important parts like motors, control boards, and sensors. Each piece needs to be of high quality. This ensures your lathe runs smoothly and lasts a long time. Quality components enhance precision, making your work more accurate.

- Motors: Provide power to move parts.

- Control Boards: Manage the movement and speed.

- Sensors: Monitor performance for accuracy.

Using well-made parts can save you time and money in the long run.

What are the main parts of a CNC retrofit kit?

The main parts include motors, control boards, sensors, and software. Each component plays a vital role in ensuring smooth operation.

Preparing Your Lathe for Retrofit

Steps to assess the current condition of your lathe. Necessary tools and workspace setup for safety and efficiency.Before you start upgrading your lathe, check its condition. Look for rust or damage. Make sure all parts move smoothly. Gather necessary tools like wrenches, screwdrivers, and safety gear. Set up a clean workspace to avoid accidents. A well-organized area helps you work efficiently. Here’s a quick list:

- Safety goggles

- Work gloves

- Protective mask

- Proper lighting

- Sturdy work surface

These steps will prepare your lathe for a smooth retrofit.

How do I check my lathe’s condition?

To assess your lathe, inspect for rust, broken parts, and proper alignment. These checks ensure your machine works well for the retrofit.

Step-by-Step Guide to Lathe CNC Retrofit

Detailed process for retrofitting a floor mount metal lathe. Common challenges and solutions during the retrofit process.Retrofitting a floor mount metal lathe to CNC involves clear steps and careful planning. First, gather all necessary tools and parts. Remove old parts, then install the new CNC components. Wiring can be tricky, so double-check connections. You might face some common issues, such as alignment problems or software glitches. Here are solutions:

- Ensure all parts are level.

- Check software settings if errors arise.

- Consult online forums for extra help.

With patience and practice, you’ll soon master this retrofit!

What are common challenges during a lathe CNC retrofit?

Common challenges include electrical issues, misalignment, and software problems. These can often be overcome with careful planning and consulting experts or online resources.

Testing and Calibration After Retrofit

Procedures for ensuring accuracy postretrofitting. Tips for maintaining and troubleshooting your retrofitted lathe.After upgrading your lathe, testing is key to success. Start by checking alignment. Use a dial indicator to see if everything is straight. Then, run a few practice cuts. This helps pinpoint any problems. If your lathe starts acting like a grumpy toddler, check the axes for smooth movement. Don’t forget to keep it clean; even lathes dislike dirt!

| Procedure | Tip |

|---|---|

| Check Alignment | Use a dial indicator |

| Run Practice Cuts | Look for issues |

| Smooth Movement | Inspect the axes |

| Keep It Clean | Dust is not your friend! |

Stay alert for odd sounds; they could signal trouble. Adjust settings gradually to fix any issues. Your lathe should work like a charm, not a loud alarm clock. Happy turning!

Case Studies: Successful Lathe CNC Retrofits

Examples of successful projects and their outcomes. Lessons learned and best practices from experienced users.Many people have made their lathe CNC retrofits a success. For example, one project changed a traditional lathe into a powerful CNC machine. This change made their work faster and easier. Users learned that planning is crucial for success. They also discovered the importance of choosing the right parts. Remember these key lessons:

- Define clear goals before starting.

- Measure twice, cut once—accuracy matters!

- Test each step along the way.

This careful approach can transform any lathe into a modern CNC tool. It can improve efficiency and increase creativity in projects.

What are some successful examples of lathe CNC retrofits?

One example is a small machine shop doubling their production speed after upgrading their lathe, thanks to a successful CNC retrofit.Cost Considerations for CNC Retrofit

Breakdown of potential costs and savings from retrofitting. Factors that influence the total expense of the project.Retrofitting a lathe can be a smart choice, but costs can add up quickly. The main expenses include parts, labor, and software. Here’s a breakdown of potential costs:

- New CNC controller: $500 – $3,000

- Servo motors and drives: $200 – $1,500 each

- Installation labor: $600 – $1,200

- Software licenses: $300 – $1,000

Factors like the type of lathe and your location can change the price. Investing in retrofitting can lead to significant savings. It may reduce waste and boost production.

What are the benefits of CNC retrofitting?

CNC retrofitting can improve efficiency and accuracy. It can also save time and money by making old machines more productive.

Future Trends in Lathe Technology

Emerging trends in CNC technology and metalworking. Predictions on the evolution of floor mount metal lathes in the market.New trends in CNC technology are shaping the future of metal lathes. These changes make machines smarter and easier to use. Companies are focusing on software upgrades and automation. This means better precision and faster production. The market will likely see more floor mount metal lathes with advanced features.

- Increased automation for smoother processes

- Enhanced software for better control

- Energy-efficient designs for sustainability

Experts predict these machines will become more affordable, making them accessible to small businesses. As technology evolves, our work with metal lathes will become quicker and more accurate.

What are the future advancements in lathe technology?

Future advancements include improved automation, better software integration, and energy-efficient operations.

Conclusion

In conclusion, retrofitting a floor mount metal lathe with CNC technology can boost its performance. You gain precision and repeatability with modern tools. This upgrade saves time and effort in your projects. If you’re interested, explore CNC kits and tutorials to start your retrofit journey. Let’s transform our old lathes into powerful machines together! Happy machining!FAQs

Sure! Here Are Five Questions Related To Lathe Floor Mount Metal Lathe Cnc Retrofit:Sure! Here are five questions about a lathe floor mount metal lathe CNC retrofit. 1. What is a CNC retrofit? A CNC retrofit changes a regular machine into a computer-controlled one. This helps it cut metal more precisely. 2. Why would we want to retrofit an old lathe? We might want to upgrade because it makes the lathe work better and faster. 3. What tools do you need for retrofitting? You will need basic tools like wrenches, screwdrivers, and a computer to help with the upgrade. 4. Can anyone do a CNC retrofit? Yes! If you follow instructions carefully, you can do it yourself with some help. 5. How does a floor mount lathe work? A floor mount lathe spins metal to shape it while you guide it. It’s like a giant spinning tool!

Sure! Please provide the question you’d like me to answer.

What Are The Key Components Needed For A Successful Cnc Retrofit Of A Floor Mount Metal Lathe?To make a floor mount metal lathe work with CNC (Computer Numerical Control), you need a few important parts. First, get a good motor to help it move. Then, install sensors so it knows where it is. You also need a control box to handle all the commands. Finally, make sure you have the right software to give instructions. With these parts, your lathe can run on its own!

How Can A Cnc Retrofit Enhance The Precision And Efficiency Of A Traditional Floor Mount Metal Lathe?A CNC retrofit makes your old lathe smarter. It adds a computer that controls the machine. This means it can turn and cut metal very accurately. You can make more parts in less time. Overall, the lathe works better and saves you money.

What Are The Potential Challenges And Solutions When Retrofitting A Lathe With Cnc Capabilities?Retrofitting a lathe with CNC (Computer Numerical Control) can be tricky. One challenge is fitting the new parts on the old machine. We might also need special tools or skills to make the changes. A good solution is to find a kit that fits, or ask an expert for help. Lastly, we should test the machine after changes to make sure it works well.

How Does The Cost Of Retrofitting A Floor Mount Metal Lathe Compare To Purchasing A New Cnc Lathe?Retrofitting a floor mount metal lathe makes it smarter and can save money. It usually costs less than buying a new CNC lathe, which is a Computer Numerical Control machine. If you already have a lathe, upgrading it can be cheaper. A new CNC lathe can be very expensive, but it comes with all the latest features. So, if you want to save money and still make good parts, retrofitting is a good choice.

What Software Options Are Available For Controlling A Retrofitted Cnc Lathe, And How Do They Integrate With Existing Hardware?You can use different software to control a retrofitted CNC lathe. Some popular options are Mach3, LinuxCNC, and GRBL. These programs help you move the tools and create parts. They connect with the machine’s existing hardware through special cables and adapters. This makes it easy for you to control everything smoothly.