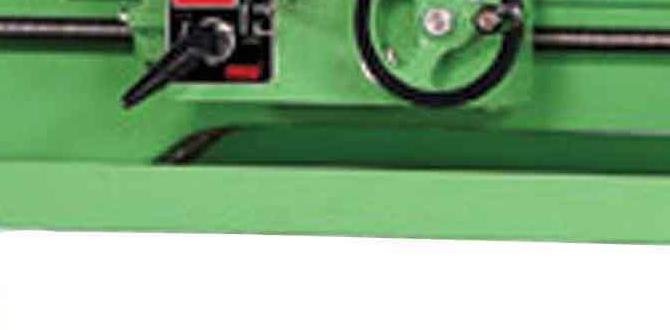

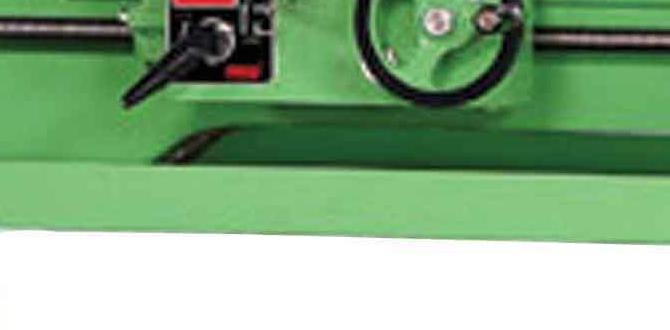

Have you ever watched a metal lathe in action? It’s like magic! A simple block of metal transforms into a precise shape right before your eyes. One important part of this process is the lathe floor mount metal lathe control panel.

This control panel is the brain of the lathe. It lets the operator make adjustments. Imagine you’re crafting a cool metal piece for a project. The control panel helps you decide how fast to spin the metal and which tools to use.

Did you know that using a control panel can make a big difference in a project’s outcome? A good control panel helps you achieve better results and boosts your confidence. Have you ever felt frustrated while working on a project? With the right control panel, those worries can fade away!

Stay with us as we explore the features and benefits of the lathe floor mount metal lathe control panel. You might just discover something new that makes your next project easier and more fun!

Lathe Floor Mount Metal Lathe Control Panel: A Detailed Guide

Lathe Floor Mount Metal Lathe Control Panel Insights

Discover the importance of the lathe floor mount metal lathe control panel. This panel helps you manage the machine’s powerful features easily. It’s key for turning materials into precise shapes. Did you know that the control panel can make your projects more efficient? With user-friendly buttons and displays, even beginners can feel like pros. Safety features are also built-in, ensuring a secure workspace. Explore how this essential tool can enhance your metalworking experience!What is a Lathe Floor Mount Metal Lathe Control Panel?

Definition and functions of the control panel. Importance in lathe operation and automation.A lathe control panel is like the brain of machine operations, controlling speed and movements. It helps you switch between different functions smoothly. Without it, a lathe would be kind of lost, like a dog looking for its tail! It is essential for automation, ensuring your lathe cuts just the right way. Think of it as the conductor of an orchestra, making sure every part works in harmony. This leads to better results and fewer mistakes.

| Function | Importance |

|---|---|

| Speed Control | Ensures accuracy in cutting. |

| Function Switching | Makes work processes smoother. |

| Safety Features | Protects operators from accidents. |

Key Features of a Lathe Control Panel

Essential components found in a metal lathe control panel. Highlighting user interface features for ease of use.A lathe control panel is like the command center of your metal lathe. It hosts essential components that make your job easier and safer. First, there are speed controls that help you adjust your lathe’s movement. You’ll also find emergency stop buttons because safety first, right? Lastly, user-friendly displays let you see all the important info at a glance. No one wants to squint while working, especially when sharp tools are around!

| Feature | Description |

|---|---|

| Speed Control | Adjusts the lathe speed for different tasks. |

| Emergency Stop | Instantly halts the machine in case of danger. |

| User Displays | Clear readouts for speed and settings. |

With a well-designed control panel, even a monkey could operate a lathe—okay, maybe not really, but you get the idea! Simplified features help every user feel like a pro, and that’s a win-win.

Benefits of Upgrading Your Lathe Control Panel

Enhancing operational efficiency and productivity. Safety features and risk mitigation in metalworking.Upgrading your lathe control panel can boost how well you work. A new panel makes it easier to use your lathe. This improves your speed and accuracy, leading to higher productivity. Additionally, modern control panels include better safety features. These designs help protect you from accidents. With improved controls, you can focus more on your work. This means less downtime due to mistakes or injuries.

Why Upgrade Your Lathe Control Panel?

A better control panel increases efficiency and safety. It keeps you busy and safe while working. Plus, it can even save you money in the long run!

Benefits of a New Control Panel

- Faster operations

- Less chance of accidents

- Better control over tasks

How to Choose the Right Control Panel for Your Lathe

Factors to consider: compatibility, ease of use, and functionality. Evaluating manufacturer reputation and support.Choosing the right control panel for your lathe is important. Start by checking compatibility with your lathe model. You want it to work well together. Look at the ease of use. A simple layout makes it easy to operate. Also, consider functionality. Does it have the features you need? Lastly, research the manufacturer’s reputation. Good support can make a big difference if anything goes wrong.

- Compatibility: Check if it fits your lathe model.

- Ease of Use: Choose a panel that is user-friendly.

- Functionality: Look for all necessary features.

Why is manufacturer support important?

Manufacturer support is key because it helps you when problems arise. Reliable support ensures you can get help quickly and get back to work.

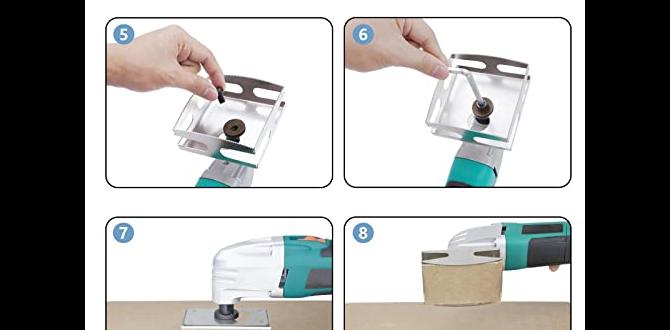

Installation Process for Lathe Control Panels

Stepbystep guide to installing a new control panel. Common pitfalls and how to avoid them during installation.Installing a new control panel can be exciting but tricky! First, gather your tools and read the manual like it’s your favorite comic book. Start by shutting off power to avoid any zaps—yikes! Next, connect the wires carefully, following color codes (red goes with red!). Check twice to avoid sending your lathe into a disco party.

Here’s a quick guide:

| Step | Action |

|---|---|

| 1 | Shut off power |

| 2 | Connect wires carefully |

| 3 | Secure the panel |

| 4 | Turn power back on |

Common pitfalls include mixing up wires or forgetting to secure the panel. Avoid these by taking your time. Remember, slow and steady wins the race, and also keeps your fingers intact!

Maintenance Tips for Lathe Control Panels

Routine checks and troubleshooting for optimal performance. Cleaning and care recommendations to prolong lifespan.Taking care of your lathe control panel is key for smooth operations. Start with routine checks—look for loose wires or funny smells. A quick glance can’t hurt! Clean the panel regularly. Dust can put a damper on its performance, and nobody wants a grumpy lathe. Consider using a damp cloth, but avoid harsh chemicals. Remember, a happy lathe is a productive lathe!

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Cleaning | Monthly |

| Deep Clean | Every 6 months |

So, keep an eye out, and give your lathe some love to prolong its lifespan. Trust me, your machinery will thank you with better performance! After all, nobody likes a control panel that throws tantrums.

User Experience: Real-world Applications and Feedback

Case studies of businesses that upgraded their control panels. User testimonials on performance improvements and issues faced.Many businesses have shared their experiences after upgrading their control panels. These upgrades often lead to better performance and efficiency. Here are some key insights:

- Increased Speed: Companies noted that machines now run faster.

- Less Downtime: Many reported fewer problems, causing less disruption.

- Simple User Interface: Workers found the new controls easy to use, which improved training time.

One user stated, “The new panel changed how we work. Tasks are quicker, and we face fewer hassles.” This feedback shows the impact of a well-designed lathe control panel on daily operations.

What are some common benefits of a control panel upgrade?

Benefits include faster operations, reduced downtime, and easier training.

Future Trends in Lathe Control Technology

Exploring advancements in automation and AI integration. Predictions on the evolution of lathe control panels in manufacturing.New technology is changing how we use lathe control panels. Automation and artificial intelligence are big parts of this change. Soon, machines will work faster and more accurately. In the future, panels may learn from each job they do. They can help make better products with fewer mistakes. Here are some expected trends:

- Increased automation for easier operation.

- Smart systems that adapt to user needs.

- Better safety features through AI.

How will lathe control panels evolve?

In the next few years, lathe control panels will likely become more user-friendly. They will offer touchscreens and voice controls. These updates will make it easier for workers to operate machines.

Experts believe that around 70% of manufacturing tasks will be automated soon. This will help save time and costs, making production smoother.

Conclusion

In summary, a lathe floor mount metal lathe control panel is essential for smooth operation. It lets you easily manage your machine’s functions. Understanding its layout and buttons will improve your skills. We encourage you to explore more about lathe operations and practice using the panel. Dive into tutorials or join a workshop to enhance your knowledge and confidence!FAQs

What Are The Essential Features Of A Control Panel For A Floor Mount Metal Lathe?A control panel for a floor mount metal lathe needs to be easy to use. It should have buttons to start and stop the machine. You also need a dial to change the speed. There should be emergency stop buttons for safety. Finally, lights or displays can show if something is wrong.

How Can The Layout Of The Control Panel Improve The Operator’S Efficiency And Safety?A good layout of the control panel helps you find buttons quickly. When everything is in the right place, you can work faster and make fewer mistakes. It also keeps important buttons close together, which makes it easier to stay safe. If something goes wrong, you can react quickly because the controls are easy to reach and see.

What Types Of Control Systems (Manual Vs. Cnc) Are Commonly Used In Floor Mount Metal Lathe Control Panels?In floor mount metal lathes, we use two main types of controls: manual and CNC. Manual controls need you to turn knobs and press buttons by hand. CNC stands for Computer Numerical Control. With CNC, a computer helps us make precise cuts and shapes automatically. Both systems help us create metal parts, but CNC is usually easier for complex tasks.

How Do You Troubleshoot Common Issues Encountered With The Control Panel Of A Metal Lathe?If the control panel of your metal lathe isn’t working, first check the power supply. Make sure it’s plugged in and the outlet works. Next, look for any loose wires or connectors. If the buttons don’t respond, press them firmly and try again. Lastly, consult the manual for specific error messages.

What Are The Best Practices For Maintaining And Cleaning The Control Panel Of A Lathe To Ensure Optimal Performance?To keep the control panel of a lathe working well, you should start by turning off the machine. Next, wipe the panel with a clean, dry cloth to remove dust and dirt. Use a soft brush to clean around buttons and knobs. Avoid using water or strong cleaners that might damage the panel. Finally, check for any loose wires or problems and fix them right away.