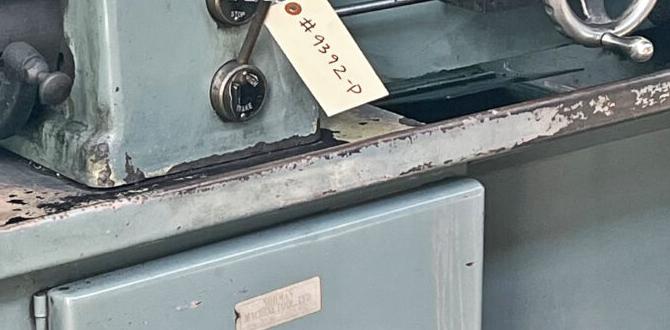

Have you ever watched a skilled worker shape metal with a machine? It’s fascinating to see a lathe in action. A floor mount metal lathe is one impressive tool. It spins metal pieces at high speeds, allowing for precise cuts and smooth finishes.

But here’s a question: How do you keep the lathe running smoothly? The answer is coolant. Coolant helps the lathe stay cool while it works. Without it, the metal can get too hot and ruin your project. Imagine wasting hours of hard work because of a simple mistake!

In this article, we will explore the importance of choosing the right coolant for your lathe floor mount metal lathe. You’ll learn how to select a coolant that boosts performance and protects your machine.

Did you know that using the right coolant can extend the life of your lathe? It can also improve the quality of your work. Let’s dive into the world of lathe coolant and discover its secrets!

Lathe Floor Mount Metal Lathe Coolant: Essential Guide

Lathe Floor Mount Metal Lathe Coolant

Lathe floor mount metal lathes need coolant for smooth operation. Coolant helps reduce heat, which can damage metal and tools. Without it, you might notice poor cuts or tool wear. Using the right coolant keeps your workspace safe and enhances your project’s quality. Did you know that a well-maintained coolant system can even extend the life of your lathe? Choosing the best coolant helps you work better and smarter. Enjoy mastering your craft with the right tools!What is a Floor Mount Metal Lathe?

Definition and basic components of a floor mount metal lathe. Key differences between floor mount and other types of lathes.A floor mount metal lathe is a machine used for shaping and cutting metal. It stands on the floor and offers stability. Key parts include the bed, headstock, tailstock, and carriage. These components work together to hold and move the metal piece.

Unlike other lathes, the floor mount type is larger and sturdier. This allows for better accuracy and can handle heavier materials. Here are some key differences:

- Stability: Stands on the floor, making it more stable.

- Size: Usually larger than bench-top lathes.

- Weight Capacity: Can work with heavier materials.

What is the benefit of using a floor mount metal lathe?

The benefit of using a floor mount metal lathe is its strength and stability, making it ideal for heavy-duty work.

Importance of Coolant in Metalworking

Role of coolant in metal cutting processes. Benefits of using coolant for metal lathe operations.The secret to smooth and successful metal cutting lies in a slippery friend: coolant! This magical liquid helps keep metal cool during lathe operations. It reduces heat, which prevents damage. A hot tool can get grouchy, just like us! Here’s why coolant is a big deal:

| Benefits of Coolant | Why It Matters |

|---|---|

| Reduces Heat | Cooler tools last longer and work better. |

| Improves Finish | Bumps and scratches? No thanks! |

| Extends Tool Life | More time with your favorite tools! |

Using coolant is like giving your tools a refreshing drink. They’ll be happier, cooler, and cut better, which is a win for everyone!

Types of Coolants for Metal Lathes

Watersoluble vs. nonwatersoluble coolants. Synthetic vs. mineralbased coolants.Choosing the right coolant is important for metal lathes. You often find two types: water-soluble and non-water-soluble. Water-soluble coolants mix with water easily. They’re great for cooling and cleaning. Non-water-soluble coolants stay thick and strong. They help protect metal parts.

Another choice is between synthetic and mineral-based coolants. Synthetic coolants are man-made. They usually provide better cooling, but can be more expensive. Mineral-based coolants come from oil. They work well and are often cheaper, but may not cool as well. Choosing the right one can help your lathe work better.

What are the types of coolants?

Water-soluble coolants mix with water and clean better.

- Non-water-soluble coolants stay thick and protect better.

- Synthetic coolants are man-made and perform better.

- Mineral-based coolants are cheaper but less effective.

Choosing the Right Coolant for Your Floor Mount Lathe

Factors to consider when selecting coolant. How machine materials affect coolant choices.Picking the right coolant for your lathe isn’t just a walk in the park; it’s more like a fun scavenger hunt! Start by thinking about how your machines work. If you’re cutting tough metal, you’ll need something stronger. On the other hand, softer materials might suit lighter coolants just fine. You also want to consider temperature and viscosity. The cooler your coolant, the happier your machine. So, keep things smooth and chill! Below is a handy table to help you:

| Material Type | Recommended Coolant |

|---|---|

| Steel | Water-Based Solutions |

| Aluminum | Light Oil |

| Copper | Emulsion |

Remember, a bad coolant choice can turn your lathe day into a bad hair day. Keep it cool, and keep it right!

Maintenance of Coolant Systems

Best practices for maintaining coolant quality and systems. Importance of regular checks and changes.Keeping coolant clean is like making sure your lemonade stays refreshing on a hot day! You need to check it regularly to avoid bad smells and gooey messes. *Regular checks* help catch any problems before they become big hassles. Dirty coolant can even mess up your machine’s performance. Think of your lathe as a car; it needs oil changes to run smoothly! Here’s a quick table with best practices for keeping that coolant in top shape:

| Practice | Description |

|---|---|

| Check Levels | Always make sure coolant is at the right level to keep things cool. |

| Change Regularly | Replace coolant every 3-6 months for best results. |

| Clean Filters | Inspect and clean filters to keep the coolant flowing. |

So, remember, calm coolant equals happy machines!

Health and Safety Considerations

Potential hazards associated with metalworking coolants. Recommended safety precautions for users.When using metalworking coolants, caution is key. These coolants can sometimes irritate your skin or eyes. Imagine getting a surprise sting after a long day at work! To keep safe, always wear gloves and goggles. A quick cleanup can save you from a slippery disaster too. Did you know that according to safety studies, proper ventilation reduces risks by up to 40%? So, make sure to open a window or use a fan while you work!

| Hazard | Precaution |

|---|---|

| Skin Irritation | Wear gloves! |

| Eye Injury | Use safety goggles! |

| Slips and Falls | Keep the floor clean! |

| Inhalation Risks | Ensure proper ventilation! |

Common Problems and Troubleshooting with Coolants

Common issues faced with lathes and coolant. Solutions and troubleshooting tips for users.Using a lathe can be fun, but coolants can sometimes be tricky. One common problem is coolant leakage. This can make a mess and waste material. Another issue is coolant mixing with chips, which can cause clogging. If this happens, your lathe might slow down. To fix these problems, make sure the coolant is filled properly and free of chips. Regular cleaning can help too. Don’t be afraid to laugh at yourself if you spill! Remember, the aim is to keep things cool!

| Problem | Solution |

|---|---|

| Coolant leakage | Check seals and refill regularly. |

| Clogged coolant | Clean out chips and maintain flow. |

Upgrading Your Coolant System

When to consider upgrading coolant systems. Benefits of modern coolant delivery systems for lathes.Upgrading your coolant system can be important for your lathe. You should consider it if your current system is old or not working well. Modern coolant systems offer better efficiency and improved cooling. This helps your machine run smoother and last longer. Here are some benefits:

- Enhanced tool life

- Reduced heat buildup

- Less pollution and waste

- Better safety and visibility

Choosing the right coolant system can make a big difference in your work quality.

When should I upgrade my coolant system?

You should upgrade your coolant system if it is outdated or not performing well. New systems improve efficiency and help machines last longer.

Conclusion

In summary, a floor mount metal lathe with coolant is essential for smooth, efficient machining. It helps cool the metal, reducing heat and wear. You can improve your projects by using coolant effectively. If you’re new to lathes, consider researching different coolant options. Learning about your tools makes you a better craftsman. Keep exploring and experimenting for the best results!FAQs

Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Coolant:Sure! Coolant helps keep the metal lathe cool while it works. It stops the machine from overheating. When we use coolant, it makes cutting easier and smoother. You should always check the coolant level. It keeps everything running well!

Sure! Please provide the question you would like me to answer.

What Are The Benefits Of Using Coolant In A Floor-Mounted Metal Lathe During Machining Operations?Using coolant in a floor-mounted metal lathe helps keep the machine cool. This prevents overheating, which can damage the metal and the lathe. Coolant also helps wash away tiny metal bits, making it safer to work. Plus, it can make your cuts smoother and look better. Overall, coolant helps the lathe work better and last longer.

How Do You Properly Select And Mix Coolant For A Floor-Mounted Metal Lathe?To select coolant for your metal lathe, choose one made for metalworking. You can find it at hardware stores. Check the label to see if it’s safe for your machine. When mixing, follow the instructions on the container. Usually, you mix water with the coolant in the right amounts. Then, stir it well before using it on your lathe.

What Are The Common Types Of Coolant Systems Available For Floor-Mounted Metal Lathes?Common types of coolant systems for floor-mounted metal lathes include flood coolants and mist coolants. Flood coolants pour a lot of liquid over the metal while you work. This helps keep things cool and clean. Mist coolants spray a fine mist of liquid that cools the metal and makes it easier to cut. Both types help you do your job better and save tools.

How Can You Maintain And Ensure The Effectiveness Of The Coolant System In A Metal Lathe?To keep the coolant system working well in a metal lathe, you should check it regularly. Make sure the coolant is clean and full. If it gets dirty, change it out for new coolant. Also, look for leaks in the pipes and fix them. Lastly, keep the filters clean so the coolant can flow easily.

What Safety Precautions Should Be Taken When Handling And Disposing Of Lathe Coolant?When handling lathe coolant, always wear gloves and safety glasses. Don’t touch your face while working. Make sure you pour it in a safe place to avoid spills. For disposal, follow local rules and never pour it down the drain. Keeping everything clean helps keep us safe!