Have you ever watched a lathe in action? It’s fascinating how metal shapes come to life! A floor mount metal lathe with a DRO, or digital readout, can make this process even smoother.

Imagine turning a simple block of metal into a precise part for a machine. Your floor mount metal lathe helps you do just that. The DRO shows you exactly how much you are cutting, making it easier to create accurate pieces.

When you work with a lathe, every measurement counts. Did you know that even a tiny mistake can change the entire project? Using a lathe with a DRO helps prevent those errors. This way, you can focus on being creative rather than worrying about mistakes.

In this article, we will explore the benefits of using a lathe floor mount metal lathe DRO. You’ll learn why it’s a must-have for metalworkers, hobbyists, and even schools. Ready to dive in and discover the world of precision machining?

Lathe Floor Mount Metal Lathe Dro: Precision And Stability

Understanding Lathe Floor Mount Metal Lathe DRO

Discover how a lathe floor mount metal lathe DRO, or Digital Readout, can change your game in machining. Imagine effortlessly measuring your cuts with precision! This tool makes it easy to track dimensions and improve accuracy. Did you know that a DRO can save you valuable time? You’ll learn how this technology enhances your work efficiency and reduces errors. Perfect for beginners and seasoned pros alike, a DRO can be your best shop companion.What is a Lathe Floor Mount Metal Lathe DRO?

Definition and function of a Digital Readout (DRO) in metal lathes. Importance of a floor mount setup in metalworking.A Digital Readout (DRO) is a nifty tool for metal lathes. It shows you exact measurements on a screen, making precision easier. Imagine trying to measure with a ruler while juggling—it’s tricky! The DRO saves you from that chaos. Having a floor mount setup is super important. It keeps things stable, so you can work without tipping over. Think of it like a solid foundation for a house—it makes everything better!

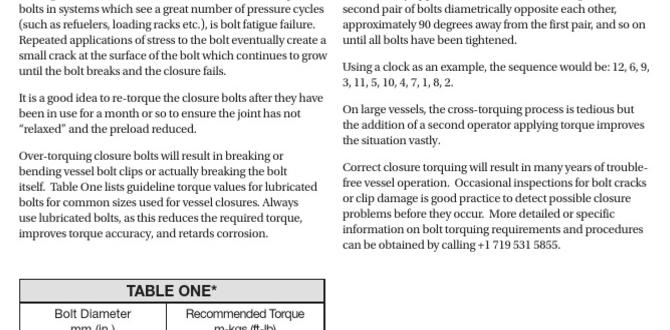

| Benefits of DRO | Floor Mount Advantages |

|---|---|

| Improves accuracy | Stability during use |

| Easy to read measurements | Ergonomic position |

| Reduces errors | Avoids wobbling |

Benefits of Using a DRO on a Metal Lathe

Enhanced precision and accuracy in measurements. Reduction of human error during machining processes.Using a DRO, or digital readout, on your metal lathe is like adding laser vision to a superhero. First, it boosts precision and accuracy in measurements, letting you cut materials with amazing exactness. No more guesswork! Second, it helps cut down on human error, making your machining processes smoother. Forget the days of wonky cuts; now, you can focus on crafting with confidence. It’s like having a buddy that always nails it on the first try!

| Benefit | Description |

|---|---|

| Enhanced Precision | Measurements are spot-on, reducing mistakes during cutting. |

| Less Human Error | Minimizes slips and fumbles, leading to smoother work. |

Key Features to Consider When Choosing a DRO

Display quality and legibility under working conditions. Mounting options and compatibility with various lathe models.Choosing the right DRO is like picking the perfect ice cream flavor. You want it to look good and work well! First, pay attention to display quality. If you can’t see the numbers clearly, it’s like trying to read in a fog! Next, think about mounting options. A good DRO should fit your lathe like a glove. Some models come with fancy brackets. Others are like “pick me up and stick me anywhere!” Just make sure it plays nicely with your lathe!

| Key Feature | Importance |

|---|---|

| Display Quality | Easy to read under all conditions |

| Mounting Options | Should fit various lathe models |

Installation Process for Lathe Floor Mount Metal Lathe DRO

Stepbystep guide to setting up a DRO on a floor mount lathe. Common challenges faced during installation and tips to overcome them.Setting up a DRO on a floor mount lathe can be simple. Follow these steps for a smooth installation:

- Start by gathering your tools.

- Next, attach the display unit to a stable spot.

- Mount the sensors on the lathe.

- Connect the cables properly.

- Calibrate the DRO for accurate readings.

Sometimes, you may face challenges. Common issues include misalignment and loose connections. To fix these:

- Double-check the measurements.

- Tighten all cables securely.

- Refer to the manual for troubleshooting tips.

With patience, you can successfully install your DRO and improve your lathe work!

What is the best way to mount the display unit?

The display unit should be mounted on a flat, sturdy surface. Make sure it’s easy to see while you work.

Maintenance Tips for Your Lathe DRO

Routine checks and calibrations to ensure accuracy. Cleaning and care for longlasting performance.Keeping your lathe dro in tip-top shape doesn’t have to be a chore. Regularly check your machine to keep it accurate. It’s like brushing your teeth; you’ll want that perfect smile, or in this case, perfect cuts! Clean your lathe often to remove dust and grime. A clean lathe is a happy lathe, and happy lathes make great projects.

| Maintenance Task | Frequency |

|---|---|

| Check calibration | Monthly |

| Clean surfaces | Weekly |

| Inspect moving parts | Every three months |

Please remember, neglected lathes can lead to errors. So, keep an eye on your machine, and it will repay you with precise creations!

Top Recommended Lathe Floor Mount Metal Lathe DRO Models

Brief reviews of popular DRO models suitable for lathes. Pros and cons of each model based on user feedback.Several lathe floor mount metal lathe DRO models stand out for their performance. Users love their accuracy and ease of use. Here’s a quick look at three popular options:

- Model A: Offers precise readings and fast installation. Some users find the display hard to read in low light.

- Model B: Known for its bright screen and durability. A downside is its higher price.

- Model C: Features a simple setup and user-friendly interface. However, some say it lacks some advanced features.

Each model has strengths and weaknesses, so choose based on your needs.

What factors should you consider when choosing a DRO?

Look for accuracy, ease of installation, and display quality. Each feature will impact your work efficiency and comfort.

Cost Analysis of Investing in a DRO for Metal Lathes

Breakdown of potential expenses associated with DRO installation. Longterm savings and return on investment for metalworking businesses.Installing a digital readout (DRO) system can seem costly at first. You need to think about various expenses. These may include:

- Purchase of the DRO unit

- Installation costs

- Maintenance over time

Will a DRO save me money?

Yes! A DRO increases efficiency and reduces costly errors, making it a smart buy for metalworking shops.

Real-World Applications of Lathe Floor Mount Metal Lathe DRO

Examples of industries and scenarios where DROs enhance productivity. Case studies showcasing improved outcomes with DRO utilization.Many industries use lathe floor mount metal lathe DROs to work smarter and faster. Factories, machine shops, and even schools benefit from them. These tools help workers make precise cuts, which saves time and materials. For example:

- Aerospace: Better accuracy leads to safer parts for airplanes.

- Automotive: Faster production helps meet customer demands.

- Education: Students learn proper techniques with real-time feedback.

Using DROs has shown significant improvements. One study found that companies saved up to 30% in production time. Another case showed a 40% drop in mistakes. These results prove lathe floor mount metal lathe DROs enhance productivity everywhere.

What are the real-world benefits of using DROs?

Using lathe floor mount metal lathe DROs leads to better accuracy and less waste. They help companies produce high-quality work while saving time and money.

Common Mistakes to Avoid When Using a Lathe DRO

Misinterpretation of digital readouts and their implications. Strategies to avoid common user errors leading to inaccuracies.Using a digital readout (DRO) on your lathe can be tricky. Sometimes, numbers can look totally different from what they really mean. Don’t let a misplaced decimal ruin your project! To avoid these mix-ups, check your settings before starting. Always double-check measurements, like a hawk on a mouse. When things go wrong, remember: it’s not the lathe’s fault, it’s your finger that forgot to heed the numbers! The following table shows common mistakes and how to avoid them:

| Mistake | Solution |

|---|---|

| Ignoring Zero Calibration | Always reset zero before starting! |

| Not Reading the Display Carefully | Take a second look; it’s worth it! |

| Forgetting Unit of Measurement | Check if it’s in inches or millimeters! |

Conclusion

In summary, a lathe floor mount metal lathe with a DRO makes metalworking easier and more precise. You get better measurements and control, which helps you create better projects. If you’re interested, consider exploring models and features that suit your needs. Learning more will help you become a skilled metalworker. Happy crafting!FAQs

What Are The Key Benefits Of Installing A Digital Readout (Dro) System On A Floor-Mounted Metal Lathe?Installing a Digital Readout (DRO) system on a metal lathe helps you see exactly how much you are moving the tool. This makes your work more accurate. You can work faster because you don’t have to measure with a ruler all the time. It also helps you avoid mistakes, making your projects turn out better. Plus, it’s easier to learn and use!

How Can A Dro Improve Precision And Efficiency When Machining Parts On A Lathe?A DRO stands for Digital Readout, and it helps you see exactly where your tool is on the lathe. With a DRO, you can measure your cuts very accurately. This means you make the right shapes and sizes without mistakes. It also saves time because you don’t have to measure everything by hand. So, using a DRO makes your work faster and better!

What Features Should I Look For When Selecting A Dro For My Lathe?When choosing a Digital Readout (DRO) for your lathe, look for a clear display. You want to see the numbers easily. Check if it has good accuracy, so your measurements are right. Also, see if it is user-friendly, making it simple to use. Lastly, think about the size and type of scales it uses. They should fit your lathe well.

Are There Specific Installation Tips Or Challenges When Mounting A Dro On A Floor-Mounted Metal Lathe?When you install a Digital Readout (DRO) on a floor-mounted metal lathe, make sure it’s level. You should use the right tools for cutting and drilling. Be careful when attaching the parts, so everything fits snugly. Check the power supply and connections to ensure they are safe. It can be tricky, but take your time and ask for help if you need it!

How Does The Cost Of A Dro System Compare To Potential Productivity Gains In A Machine Shop Environment?A Digital Readout (DRO) system can cost a bit of money, but it helps you work faster. With a DRO, you can measure things accurately, which saves time. This means you can make more parts each day. Overall, spending money on a DRO can help your machine shop earn more money by being more productive.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Benefits Of Installing A Digital Readout (Dro) System On A Floor-Mounted Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Installing a Digital Readout (DRO) system on a metal lathe helps you see exactly how much you are moving the tool. This makes your work more accurate. You can work faster because you don’t have to measure with a ruler all the time. It also helps you avoid mistakes, making your projects turn out better. Plus, it’s easier to learn and use!”}},{“@type”: “Question”,”name”: “How Can A Dro Improve Precision And Efficiency When Machining Parts On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A DRO stands for Digital Readout, and it helps you see exactly where your tool is on the lathe. With a DRO, you can measure your cuts very accurately. This means you make the right shapes and sizes without mistakes. It also saves time because you don’t have to measure everything by hand. So, using a DRO makes your work faster and better!”}},{“@type”: “Question”,”name”: “What Features Should I Look For When Selecting A Dro For My Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a Digital Readout (DRO) for your lathe, look for a clear display. You want to see the numbers easily. Check if it has good accuracy, so your measurements are right. Also, see if it is user-friendly, making it simple to use. Lastly, think about the size and type of scales it uses. They should fit your lathe well.”}},{“@type”: “Question”,”name”: “Are There Specific Installation Tips Or Challenges When Mounting A Dro On A Floor-Mounted Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you install a Digital Readout (DRO) on a floor-mounted metal lathe, make sure it’s level. You should use the right tools for cutting and drilling. Be careful when attaching the parts, so everything fits snugly. Check the power supply and connections to ensure they are safe. It can be tricky, but take your time and ask for help if you need it!”}},{“@type”: “Question”,”name”: “How Does The Cost Of A Dro System Compare To Potential Productivity Gains In A Machine Shop Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A Digital Readout (DRO) system can cost a bit of money, but it helps you work faster. With a DRO, you can measure things accurately, which saves time. This means you can make more parts each day. Overall, spending money on a DRO can help your machine shop earn more money by being more productive.”}}]}