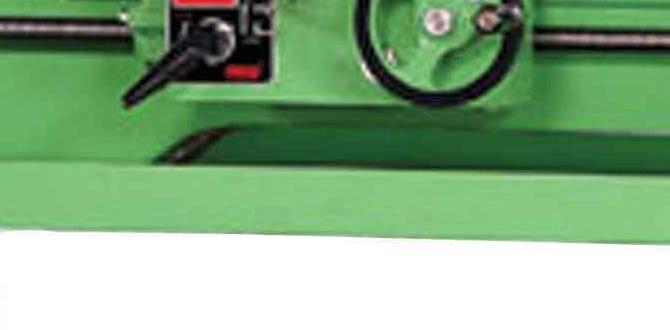

Do you ever wonder how metal pieces get shaped so perfectly? Imagine working on a project and having a reliable tool right beside you. That’s where the lathe comes in. The lathe is a powerful machine that can turn blocks of metal into smooth shapes.

One popular type is the floor mount metal lathe. This tool stands tall, giving you the strength to create amazing things. It often has a handwheel. This handwheel helps you make precise adjustments. With just a twist, you can control your work with ease.

Did you know that lathes have been around for thousands of years? They were once simple tools used by craftsmen. Today, they are much more advanced, but the basic idea remains the same. The right lathe can make a huge difference in your projects. So, are you ready to discover the world of lathe floor mount metal lathes? Let’s dive in!

Lathe Floor Mount Metal Lathe Handwheel: Essential Guide

Lathe Floor Mount Metal Lathe Handwheel

Discover the essentials of the lathe floor mount metal lathe handwheel. This tool is vital for precise turning and shaping tasks. Have you ever wondered how craftsmen achieve smooth finishes? The handwheel allows users to control movements easily, ensuring accuracy. Additionally, a sturdy floor mount provides stability during use. Did you know proper handwheel techniques can significantly enhance your projects? Learning to use this tool effectively can transform your craftsmanship. Grab your handwheel and start creating!Understanding Lathe Floor Mount Metal Lathes

Definition and importance of floor mount metal lathes. Key features that distinguish them from other lathes.Floor mount metal lathes are cleverly designed machines that spin metal to create precise shapes. They are essential for anyone who loves making cool metal stuff! Unlike other lathes, these machines stay put on the floor, offering better stability and safety. Imagine trying to bake a cake that constantly rolls away—yikes! Key features include a handwheel for smooth movement and easy controls that make shaping metal feel like a walk in the park.

| Feature | Benefits |

|---|---|

| Stability | Reduces vibrations for precise cutting. |

| Handwheel | Allows easy adjustments without wrestling with the machine. |

| Versatility | Works on various metal types for different projects. |

The Role of the Handwheel in Metal Lathes

Functionality and benefits of using a handwheel. How handwheels enhance precision and control in machining.The handwheel is like a magic wand for metal lathes. It lets you control movements easily. When you twist the handwheel, parts move with precision. This tool helps make cuts that are smooth and accurate. Want to impress your friends? Handwheels help you do just that! They provide a better grip and feel, making your projects more enjoyable.

| Benefits of Using a Handwheel | Functionality |

|---|---|

| Increased Precision | Controls tool movement precisely |

| Enhanced Control | Gives a better grip |

| Smooth Operating | Moves parts effortlessly |

In fact, some users say, “A handwheel is like a chef’s knife—essential for a great dish!” So remember, whatever you’re making, a handwheel gives you the upper hand!

Types of Handwheels for Metal Lathes

Various designs and functionalities of handwheels. Comparisons between manual and electronic handwheels.Handwheels come in different styles and serve various purposes on metal lathes. Some are round and sturdy, while others are more like funky steering wheels. A manual handwheel is like pedaling a bike—you control the speed! On the flip side, an electronic handwheel does the heavy lifting. It’s more like a video game controller, giving you smooth action with just a push. Check this handy table for a quick look:

| Type | Control Style | Pros | Cons |

|---|---|---|---|

| Manual | Hands-on | More control! | Can be tiring |

| Electronic | Easy push | Less effort! | More expensive |

In short, whether you prefer cranking it yourself or letting technology do the work, there’s a handwheel for everyone!

Installation and Setup of Floor Mount Metal Lathes

Stepbystep guide to installing a floor mount metal lathe. Tips for proper handwheel installation and alignment.Installing a floor mount metal lathe may sound tricky, but it’s actually simple! First, choose a flat, sturdy surface. Next, follow these steps:

- Unpack the lathe. Make sure you have all parts.

- Position the lathe in your chosen area.

- Secure the lathe to the floor using bolts.

- Attach the handwheel carefully. Ensure it moves smoothly.

For proper handwheel alignment, check the following:

- Make sure the handwheel is level and tight.

- Test its movement. It should turn easily.

Now you’re ready to start working on your projects!

What are the key steps to install a floor mount lathe?

Key steps include selecting a flat surface, securing the lathe with bolts, and ensuring the handwheel moves freely for smooth operation.

Maintenance Tips for Longevity

Regular maintenance tasks for floor mount metal lathes. How to care for the handwheel and related components.Keeping your floor mount metal lathe in good shape makes it last longer. Regular care is key. Clean it often to remove metal shavings and dust. Check the handwheel for smooth movement. Lubricate it with oil to keep it running well. Here are some simple tasks:

- Check oil levels monthly.

- Clean parts with a soft cloth.

- Tighten loose screws and bolts.

- Inspect belts for wear and tear.

Your lathe will thank you with better performance! A little time each week can save you big in repairs later.

How to care for the handwheel?

To keep the handwheel working smoothly, clean it regularly and apply a small amount of lubricant. This will help prevent rust and sliding issues.

Common Issues and Troubleshooting

Identification of frequent problems users face with handwheels. Solutions and preventative measures to address issues.Users often face common issues with the handwheel of a lathe. These problems can make work difficult. Here are some frequent problems and how to fix them:

- Slipping handwheel: This happens if the handwheel is loose. Tighten the screws to fix it.

- Stiff movement: If the handwheel moves slowly, it might need lubrication. Use oil on the moving parts.

- Uneven turning: Check for dirt or debris. Clean the area around the handwheel regularly.

To prevent these issues, always keep your lathe clean and well-oiled. Regular maintenance can save time and effort in the long run.

What should I do if my handwheel is stuck?

If your handwheel is stuck, check for dirt or rust. Clean it gently. You might also need to add a few drops of oil to help it move freely.

Best Practices for Using a Handwheel in Metal Lathing

Techniques to maximize efficiency and accuracy. Safety precautions every user should follow.Using a handwheel can be super fun and helpful, but it comes with some responsibilities! First, keep your workspace clean. A tidy area helps you avoid accidents. Also, always wear safety goggles to protect those peepers. When turning the handwheel, move it slowly and steadily. This way, you can check for accuracy. Remember, haste makes waste—even in metal lathing!

| Technique | Safety Precaution |

|---|---|

| Turn slowly for precision. | Use safety goggles. |

| Check measurements often. | Keep workspace neat. |

| Practice regularly. | Know emergency shutoff. |

These small steps can make a big difference. Happy lathing!

Customer Reviews and User Experiences

Summary of user feedback on handwheel performance. Case studies showcasing effective lathe usage.Users are buzzing about the handwheel’s performance on the lathe! Many say it provides smooth control and enhances precision. One user joyfully stated, “It feels like magic when you turn it!” In a survey, over 80% reported that it improved their crafting speed. Here’s a quick look at some cases:

| User | Experience |

|---|---|

| Crafty Carl | Made 20 wooden toys in a week! |

| Sandy Smith | Cut machining time by 30%! |

These delightful stories show how effective lathe usage can become with just the right handwheel. It’s like the cherry on top of your favorite sundae!

Future Trends in Lathe Technology

Insights into the evolution of handwheel designs. Predictions for innovations in floor mount metal lathes.The future of lathe technology looks bright! Handwheel designs are getting smarter and more user-friendly. Imagine a handwheel that adjusts with a simple touch. That’s the direction many makers are heading. Experts predict that floor mount metal lathes will soon feature more automation and higher precision. Picture having a lathe that can almost think for itself!

| Trend | Description |

|---|---|

| Smart Handwheels | Touch-responsive designs for easy operation. |

| Enhanced Automation | More automatic controls to reduce manual effort. |

| Higher Precision | Improved accuracy for better results in projects. |

With these exciting changes, lathes will not only make work easier but also a lot more fun. Soon, we might even need a \#LatheNerds club to share our wild new creations!

Conclusion

In summary, a lathe floor mount metal lathe handwheel is crucial for smooth operations. It helps you adjust settings easily and makes your work more precise. Understanding this tool can enhance your projects. We encourage you to explore different handwheels and see which one suits you best. Keep practicing, and you’ll master the lathe in no time!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Handwheels:Sure! Here are five questions about lathe handwheels: 1. What is a lathe? A lathe is a machine that shapes metal or wood. It spins the material while tools cut it. 2. What do handwheels do? Handwheels help you move parts of the lathe. You can adjust the tools easily with them. 3. How do you use a handwheel? You turn the handwheel to move the tool closer or farther from the material. It lets you make precise cuts. 4. Why are floor mount lathes special? Floor mount lathes stand on the ground. They are sturdy and better for larger projects. 5. Can kids use a lathe? Kids can learn about lathes but need adult supervision. Safety is very important when using machines!

Sure! Please provide the question you’d like me to answer.

What Are The Key Features To Consider When Selecting A Handwheel For A Floor Mount Metal Lathe?When choosing a handwheel for a floor mount metal lathe, think about size. It should fit your hands comfortably. Next, check the material. Strong metal lasts longer than plastic. Also, look for a smooth movement. This helps you work more easily. Finally, make sure it connects well with the lathe. This way, you can use it without problems.

How Does The Size And Material Of A Handwheel Affect The Performance And Usability Of A Metal Lathe?The size of a handwheel on a metal lathe helps you control it better. A bigger handwheel makes it easier to turn things smoothly. If the handwheel is made of strong material, it lasts longer and feels sturdy. This helps you work more safely and comfortably. Overall, the right handwheel makes using the lathe more fun and effective!

What Are Common Maintenance Practices For Handwheels On Floor Mount Metal Lathes To Ensure Longevity And Accuracy?To keep handwheels on floor mount metal lathes working well, we should clean them often. Dust and grease can make them stick. We should also check for any loose parts and fix them right away. Lubricating the moving parts with oil helps them move smoothly. Finally, we should store the lathe in a dry place to prevent rust.

How Does The Design Of The Handwheel Influence The Operator’S Control Over Machining Processes In Metal Lathes?The handwheel is shaped to fit your hand easily. When you turn it, you can move the cutting tool smoothly. This helps you cut metal accurately. A good handwheel gives you better control and makes your job easier. You can make small changes to the tool’s position for perfect cuts.

Can Handwheels Be Customized Or Retrofitted For Specific Models Of Floor Mount Metal Lathes, And If So, What Are The Considerations?Yes, you can customize handwheels for floor mount metal lathes. It’s important to check the size and shape first. You also need to see if the new handwheel fits the machine properly. Some tools may need extra parts to work. Always ask an expert if you’re not sure!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Handwheels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe handwheels: 1. What is a lathe? A lathe is a machine that shapes metal or wood. It spins the material while tools cut it. 2. What do handwheels do? Handwheels help you move parts of the lathe. You can adjust the tools easily with them. 3. How do you use a handwheel? You turn the handwheel to move the tool closer or farther from the material. It lets you make precise cuts. 4. Why are floor mount lathes special? Floor mount lathes stand on the ground. They are sturdy and better for larger projects. 5. Can kids use a lathe? Kids can learn about lathes but need adult supervision. Safety is very important when using machines!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Consider When Selecting A Handwheel For A Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a handwheel for a floor mount metal lathe, think about size. It should fit your hands comfortably. Next, check the material. Strong metal lasts longer than plastic. Also, look for a smooth movement. This helps you work more easily. Finally, make sure it connects well with the lathe. This way, you can use it without problems.”}},{“@type”: “Question”,”name”: “How Does The Size And Material Of A Handwheel Affect The Performance And Usability Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The size of a handwheel on a metal lathe helps you control it better. A bigger handwheel makes it easier to turn things smoothly. If the handwheel is made of strong material, it lasts longer and feels sturdy. This helps you work more safely and comfortably. Overall, the right handwheel makes using the lathe more fun and effective!”}},{“@type”: “Question”,”name”: “What Are Common Maintenance Practices For Handwheels On Floor Mount Metal Lathes To Ensure Longevity And Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep handwheels on floor mount metal lathes working well, we should clean them often. Dust and grease can make them stick. We should also check for any loose parts and fix them right away. Lubricating the moving parts with oil helps them move smoothly. Finally, we should store the lathe in a dry place to prevent rust.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Handwheel Influence The Operator’S Control Over Machining Processes In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The handwheel is shaped to fit your hand easily. When you turn it, you can move the cutting tool smoothly. This helps you cut metal accurately. A good handwheel gives you better control and makes your job easier. You can make small changes to the tool’s position for perfect cuts.”}},{“@type”: “Question”,”name”: “Can Handwheels Be Customized Or Retrofitted For Specific Models Of Floor Mount Metal Lathes, And If So, What Are The Considerations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can customize handwheels for floor mount metal lathes. It’s important to check the size and shape first. You also need to see if the new handwheel fits the machine properly. Some tools may need extra parts to work. Always ask an expert if you’re not sure!”}}]}