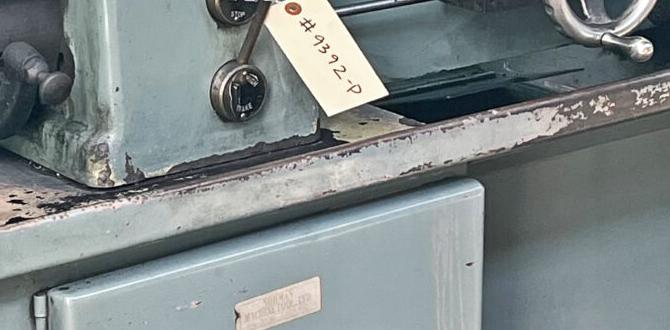

Imagine walking into a workshop and seeing a powerful machine resting proudly on the floor. This is no ordinary machine; it’s a lathe, specifically a floor mount metal lathe. Have you ever wondered how craftsmen create beautiful shapes from solid metal? The secret often lies in the lathe’s quill.

The quill is like a helper that lets you make precise cuts. It moves in and out to guide the tool. This makes your work easy and accurate. Many hobbyists and professionals love using a lathe because it brings their ideas to life.

Fun fact: Did you know that lathes have been used for thousands of years? They have evolved from simple tools to the advanced floor mount models we use today. Whether you want to craft metal pieces or just explore your creativity, a lathe floor mount metal lathe quill is your ticket to discovery!

Lathe Floor Mount Metal Lathe Quill: A Comprehensive Guide

Understanding the Lathe Floor Mount Metal Lathe Quill

The lathe floor mount metal lathe quill plays a crucial role in machining projects. This part helps you make precise adjustments while cutting metal. Imagine needing to drill a hole perfectly straight; the quill allows for easy movement to achieve that. Did you know that a well-maintained quill can enhance the life of your lathe? By learning to care for it, you improve both performance and safety. Explore how mastering this tool can make your projects easier and more fun!What is a Floor Mount Metal Lathe?

Definition and basic components. Advantages of using a floor mount design.A floor mount metal lathe is a special tool used for shaping metal. It stands on the floor, making it strong and stable. Basic parts include a rotating spindle, cutting tools, and a bed where the workpiece sits. This setup is great for many reasons:

- Stability: It doesn’t move easily, ensuring safety.

- Space-saving: More space for your tools and materials.

- Power: Can handle large pieces of metal with ease.

With a floor mount lathe, users can create more precise parts. This tool helps in making everything from small gadgets to big machinery.

Why choose a floor mount metal lathe?

Many choose this lathe for its strength and accuracy. A floor mount model can hold larger items, leading to better results and reduced mistakes.

Understanding the Quill Mechanism

Explanation of the quill function in lathes. Comparison with other mechanisms (tailstock, etc.).The quill in a lathe works like a magical pencil, helping you move tools in and out smoothly. It’s easy to control and gives you precise cuts. Unlike the tailstock, which holds tools stationary, the quill allows for quick adjustments. Think of it like flipping to your favorite comic page—fast and fun! Here’s a quick comparison:

| Mechanism | Function |

|---|---|

| Quill | Moves tools in and out easily |

| Tailstock | Holds tools firmly in place |

The quill makes your work smoother, while the tailstock stays put. So, next time you’re using a lathe, remember: the quill is your tool buddy, always ready for action!

Key Features of a Quality Lathe Quill

Material and durability considerations. Precision and accuracy factors.Choosing the right lathe quill is important. Material and durability play a big role in how long it lasts. High-quality quills are often made of sturdy metals, ensuring they won’t break easily. Precision and accuracy make a difference, too. A good quill allows for tight tolerances, which means better finished projects. You want your cuts to be exact.

What materials are best for lathe quills?

Metals like steel and aluminum are ideal for lathe quills. They provide strength and longevity.

Key features include:

- Strong metal for durability.

- Lightweight for ease of use.

- Precision design for accuracy.

How to Choose the Right Floor Mount Metal Lathe

Factors to consider: size, power, and features. Importance of brand reputation.Buying a floor mount metal lathe can be exciting, like picking a pet! First, think about the size. Make sure it fits your workspace and your projects. Next, consider the power. A stronger motor can handle tougher jobs, so don’t skimp. Lastly, check the features. Do you need digital readouts or easy adjustments? Remember, a trusted brand means more reliability. After all, you won’t want your lathe to take an unexpected vacation!

| Factor | Importance |

|---|---|

| Size | Must fit your space and needs |

| Power | Handles tougher jobs |

| Features | Enhances usability |

| Brand Reputation | Promotes reliability |

Installation Process of a Floor Mount Metal Lathe Quill

Stepbystep guide for installation. Common pitfalls and how to avoid them.Installing a floor mount metal lathe quill can seem tricky, but it’s all about following steps. First, ensure you have all tools nearby, like a wrench and screws. Second, position the lathe on a sturdy surface. Tighten bolts like you’re securing a treasure chest—snug but not too tight!

Watch out for common mistakes. Don’t forget to double-check the alignment. If something’s off, your lathe might become more of a spinning top than a precision tool!

| Common Pitfalls | How to Avoid |

|---|---|

| Loose Bolts | Tighten them well! |

| Poor Alignment | Use a level tool to line up! |

| Missing Parts | Take a checklist before starting! |

Just like baking cookies, you must follow the recipe! If you do, you’ll have a lathe that runs smoothly and a project that’s a sweet success.

Maintenance Tips for Longevity

Routine maintenance practices for lathe and quill. Troubleshooting common quill issues.Taking care of your lathe and quill is key to keeping them in tip-top shape. Regular cleaning is like brushing your teeth—no one wants a grumpy tool! Wipe down your machine after each use to avoid dust and chips building up. Check oil levels, too. A little grease goes a long way in keeping things smooth!

| Maintenance Tip | Action |

|---|---|

| Clean Regularly | Wipe down after each use |

| Check Oil | Ensure it’s well-lubed to prevent squeaks |

| Inspect Quill | Look for any wobbling or issues |

For quill problems, a little detective work can save the day. If it’s stuck, check for debris. And if it’s wobbling, adjustments might be needed. Remember, a happy quill makes a happy maker!

Applications of Floor Mount Metal Lathes

Industries that commonly use these lathes. Types of projects suited for floor mount lathes.Floor mount metal lathes are like the superheroes of many industries. They work wonders in the automotive and aviation fields, helping create parts that zoom around at high speeds. These machines are also popular in woodworking and metalworking shops, turning raw materials into beautiful, precise objects. Projects like making car parts, tools, and even artistic sculptures can thrive here. It’s a magical place where metal and creativity collide! Check out this handy table for ideas:

| Industry | Common Projects |

|---|---|

| Automotive | Engine components, custom parts |

| Aerospace | Aircraft fittings, prototypes |

| Woodworking | Wooden furniture legs, artistic pieces |

| Metalworking | Tools, fixtures |

So, whether you’re crafting a tiny gear or a massive sculpture, these machines have got your back!

Upgrading Your Floor Mount Metal Lathe Quill

Signs that indicate a need for an upgrade. Recommendations for suitable upgrades.Upgrading your lathe floor mount metal lathe quill can make a big difference. Some signs show it’s time for an update. If you notice uneven cuts, strange noise, or rust, it’s time to act. These issues can affect your work quality. Consider these upgrades:

- New bearings for smoother operation

- Enhanced quill locks for better control

- Upgraded tooling that fits your needs

These changes can make your lathe work better and last longer.

What are the signs you need an upgrade?

Common signs include poor performance, noise, or visible wear. If your lathe struggles, it’s time for a closer look.

User Experiences and Reviews

Summary of user feedback on top models. Importance of user insights for prospective buyers.Many users have praised the top models of the lathe floor mount metal lathe quill for their precision and ease of use. Feedback highlights key features like durability and smooth operation. These insights help prospective buyers make informed choices. User reviews often note:

- Strong build quality.

- Accurate cutting results.

- Simple setup and operation.

Knowing what others think can guide buyers to the best choice for their needs.

What do users say about their experience?

Users often report satisfaction with product performance and support. They mention how easy it is to make adjustments and the effectiveness of the lathe in various projects.

Conclusion

In conclusion, a lathe floor mount metal lathe quill is essential for precision work. It helps you adjust the tool accurately for better results. Understanding its features can improve your projects. We encourage you to explore different models and read more to find the right fit for your needs. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Quills:Sure! A lathe is a machine we use to shape metal. The quill is a part that helps hold and move tools. When you use a floor mount lathe, it stays stable on the ground. This makes it easier for you to work accurately. Always take care when using machinery for safety!

Sure! Please give me a question you’d like me to answer.

What Is The Primary Function Of A Quill In A Floor Mount Metal Lathe?The quill in a floor mount metal lathe helps you move tools up and down. It acts like a holder for the cutting tools. When you turn a handle, the quill moves the tool closer to or farther from the metal. This way, we can make precise cuts and shapes. It is an important part for getting good results in our work!

How Do You Adjust The Quill For Different Machining Operations In A Lathe?To adjust the quill on a lathe, start by loosening the quill lock. Then, turn the handle to move the quill up or down. You want it to be at the right height for your tool. After adjusting, tighten the quill lock again to keep it in place. Now you’re ready for your machining!

What Are The Key Differences Between A Quill And Other Types Of Spindle Assemblies In Metal Lathes?A quill is a part of a lathe that holds the cutting tool. It can move in and out, helping you adjust the tool’s position easily. Other spindle assemblies are usually fixed and do not move. This means a quill is more flexible for different tasks compared to fixed spindles. Quills make it easier for you to make precise cuts.

What Maintenance Practices Are Recommended To Ensure The Longevity And Accuracy Of A Lathe Quill?To keep your lathe quill working well, you should clean it regularly. Make sure to oil the moving parts to help them move smoothly. Check for any loose screws and tighten them. It’s also a good idea to store it in a dry place to avoid rust. These steps will help your lathe quill last longer and work better!

How Can You Troubleshoot Common Issues Related To The Quill, Such As Alignment Or Movement Problems?To fix quill problems, first check if it’s lined up straight. You can do this by adjusting the screws or knobs. Next, see if it moves smoothly by giving it a gentle push. If it sticks, clean any dirt around it. Finally, make sure there are no loose parts that need tightening.