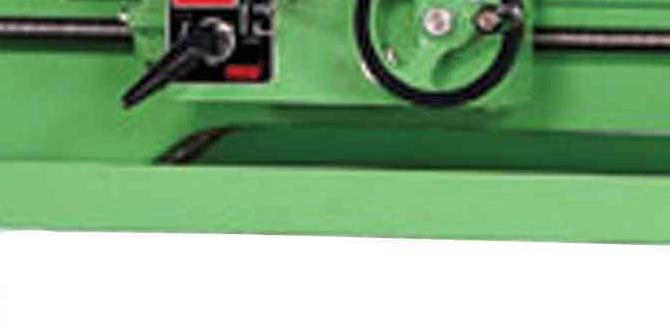

Have you ever seen a metal lathe in action? It’s like watching magic unfold as metal turns into precise shapes. But to make that happen, you need the right setup. A lathe floor mount metal lathe setup can transform your workshop into a hub of creativity.

Picture this: you walk into your garage, and there it is, a sturdy lathe waiting for you. It feels exciting, doesn’t it? Setting up a floor mount metal lathe might seem tricky at first, but it’s worth it. With the right tools and a little guidance, you can do it yourself!

Here’s a fun fact: Did you know that lathes have been around for thousands of years? They have shaped wood, metal, and even stone! Today’s lathes are much more advanced but still rely on the same basic principles.

Why not dive in? In this article, we’ll explore everything you need to know about lathe floor mount metal lathe setups. Let’s get you started on your journey to becoming a master craftsman!

Complete Guide To Lathe Floor Mount Metal Lathe Setup

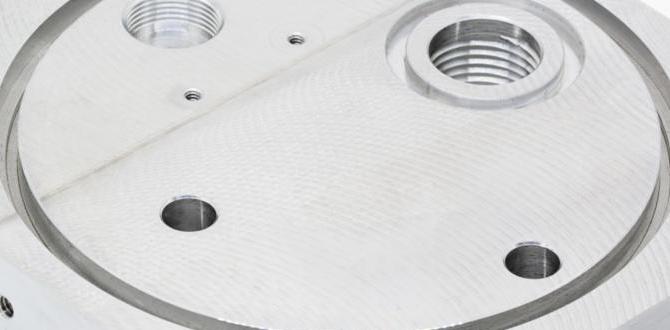

Lathe Floor Mount Metal Lathe Setup

Setting up a floor mount metal lathe can be both exciting and challenging. First, check the space where you’ll place the lathe. A clear, sturdy floor is important for safety. Next, level the lathe with adjusters to avoid vibrations during use. Many people forget to secure their tools properly, which can lead to accidents. Did you know that a well-set lathe can improve your project’s accuracy? Understanding these key steps can make your metalworking experience smoother and more enjoyable!Understanding Lathe Floor Mount Metal Lathes

Definition and purpose of floor mount metal lathes. Advantages of using floor mount lathes over other types.Floor mount metal lathes are special machines designed for shaping metal. They hold the metal pieces steadily while spinning them. This setup makes it easier to cut and shape metal accurately. One great thing about floor mount lathes is their stability. Unlike smaller lathes, they don’t wiggle as much. This means better results! Plus, they save space since they stand tall instead of spreading out. As they say, “Why be flat when you can stand tall?”

| Advantages of Floor Mount Lathes |

|---|

| Stability: Less wobbling while you work. |

| Space-Saving: Designed to take up less floor space. |

| Precision: Makes accurate cuts easier. |

Choosing the Right Location for Your Lathe

Importance of spatial requirements and layout. Considerations for ventilation and lighting.Finding the perfect spot for your lathe is like choosing the best seat in a movie theater—it’s vital! You need enough space to move around safely. Don’t forget about ventilation; nobody wants to breathe in dust like it’s a new snack flavor. Lighting also matters; bright lights help you see what you’re doing. Here’s a quick guide:

| Consideration | Importance |

|---|---|

| Space | Room to move and work |

| Ventilation | Fresh air and safety |

| Lighting | Visibility for precision |

Choose wisely, and your lathe will thank you by making some fantastic creations (along with your fingers staying intact)!

Essential Tools and Materials for Setup

List of necessary tools for assembling a lathe. Recommended materials and their properties.Setting up a lathe requires some important tools and materials. First, you need a sturdy workbench. A good bench holds everything steady, preventing your projects from wobbling like a jelly on a plate. Other essential tools include a wrench for adjusting parts, a caliper for precision measuring, and a screwdriver for minor tweaks. For materials, good quality metal is vital, as it can withstand the heat and pressure during operation. For clarity, here’s a handy table:

| Tool/Material | Purpose |

|---|---|

| Workbench | Support and stability |

| Wrench | Adjusting parts |

| Caliper | Measuring accuracy |

| Screwdriver | Tightening screws |

| High-Quality Metal | Durability and heat resistance |

Gather these, and you’ll be ready to tackle your lathe projects without breaking a sweat! Remember, the right tools make every job a little less tricky and a lot more fun!

Step-by-Step Guide to Setting Up a Floor Mount Lathe

Preparing the workspace for installation. Detailed assembly instructions.First, clear a space that’s big enough for your lathe. You don’t want it feeling cramped like a sardine can! Next, gather your tools and read the manual—it’s like the treasure map for your machine. You’ll need a wrench, screws, and maybe a snack or two; we all get hungry! Now, carefully follow each step of the assembly instructions. Remember to check if all parts are there; nobody likes missing pieces like socks in the dryer!

| Tools Needed | Steps for Assembly |

|---|---|

| Wrench | Start with the base assembly. |

| Screws | Connect the motor securely. |

| Owner’s Manual | Follow the instructions carefully. |

Leveling and Aligning Your Lathe

Importance of leveling for precision work. Techniques for ensuring correct alignment.Having a level lathe is crucial for precise work. When your lathe is out of level, cuts can be uneven, leading to mistakes. To ensure correct alignment, start with a bubble level. Place it on the lathe bed and adjust the feet until the bubble is centered. Check both ends of the lathe. Regularly recalibrating will help you maintain accuracy.

Why is leveling important for my lathe?

Leveling helps ensure smooth and accurate cuts, reducing errors and improving overall work quality.

Techniques for Proper Alignment:

- Use a bubble level to check flatness.

- Adjust the feet based on level readings.

- Recheck alignment frequently for best results.

Safety Precautions During Setup and Operation

Essential safety gear and equipment. Best practices for safe operation of the lathe.Using the right safety gear is important when working with a lathe. Always wear goggles to protect your eyes. Ear protection is key too, as lathes can be loud. Keep your hands and loose clothing away from moving parts. Following best practices helps keep you safe. Always check the lathe before use. Make sure it’s clean and in good shape. Use tools properly and never rush your work. Safety first means better results!

What safety gear should I wear when setting up a lathe?

Goggles protect your eyes, while earplugs minimize noise. Don’t forget gloves to prevent cuts!

Best Practices for Safety:

- Inspect tools and machine before use

- Keep the area tidy

- Use the right tools properly

- Never rush your work

Maintenance Tips for Longevity and Performance

Regular maintenance routines and checks. Signs of wear and necessary corrective actions.Keeping your lathe in top shape is like caring for a pet. It needs regular check-ups! Clean the machine often to remove dust and debris. Look for unusual noises or vibrations; these might signal trouble. If a part looks worn, don’t wait! Replace it before it causes chaos. Schedule routine maintenance every few months. Remember, a happy lathe means smooth work, and nobody wants a cranky machine ruining their fun!

| Maintenance Task | Frequency | Signs of Wear |

|---|---|---|

| Clean the machine | Every week | Dirt buildup |

| Check belts and gears | Monthly | Cracks or fraying |

| Lubricate moving parts | Every three months | Rough movement |

Common Issues and Troubleshooting

Identifying frequent setup problems and their solutions. Tips for optimizing lathe performance after setup.Many people face problems during the lathe setup. Common issues include misalignment and loose parts. If your lathe is shaking, check the feet. Ensure they are stable and firmly on the ground. If parts are loose, tighten bolts and screws. Regular maintenance helps optimize performance. Clean the machine and lubricate moving parts. Remember, a well-maintained lathe runs smoothly.

What should you check if your lathe isn’t cutting well?

Look for dull tools, correct speed settings, and proper feed rates. Using sharp tools helps achieve cleaner cuts. Adjust speed according to the material type. Proper settings make a big difference!

Conclusion

In summary, a floor mount metal lathe setup is important for stability and precision in your projects. Ensure you choose a sturdy area and secure your lathe properly. Remember to follow safety practices always. Now that you have these insights, you can start setting up your lathe. For more tips, check out beginner guides or video tutorials online!FAQs

Sure! Here Are Five Related Questions On The Topic Of Setting Up A Floor-Mounted Metal Lathe:Sure! Here are five related questions about setting up a floor-mounted metal lathe: 1. What do we need to set up a lathe? 2. How do we level the lathe properly? 3. What safety gear should we wear? 4. What should we check before using it? 5. How do we start the lathe for the first time? These questions will help you learn about using a lathe safely and correctly.

Of course! Please share the specific question you would like me to answer.

What Are The Essential Conditions And Requirements For The Proper Placement Of A Floor Mount Metal Lathe In A Workshop?To place a floor mount metal lathe properly in your workshop, you need enough space around it. Make sure the floor is strong to hold the weight. Place it on a flat and level surface so it works well. You should have good lighting to see what you’re doing. Lastly, keep it near power sources so you can plug it in easily.

How Do You Level A Floor-Mounted Metal Lathe To Ensure Accurate Machining And Minimize Vibrations During Operation?To level a floor-mounted metal lathe, first, find a flat surface. You can use a spirit level, which shows if something is straight. Place the lathe on the ground and adjust its feet until the level bubble is in the center. Tighten the feet to keep everything in place. This way, the lathe will work better and make less shaking noise.

What Safety Precautions Should Be Considered When Setting Up A Floor-Mounted Metal Lathe?When you set up a floor-mounted metal lathe, make sure to wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so they don’t get caught in the machine. Always check that the lathe is on a stable floor and won’t move. Make sure to keep your hands and tools away from the spinning parts. Finally, read the machine’s manual to understand how to use it safely.

What Tools And Equipment Are Necessary For The Proper Installation And Setup Of A Floor-Mounted Metal Lathe?To set up a floor-mounted metal lathe, you need a few important tools and equipment. First, you’ll need wrenches to tighten bolts. A level helps you keep the lathe flat and straight. Using a screwdriver will help with smaller adjustments. Finally, you might need a measuring tape to ensure everything is in the right spot.

How Can You Optimize The Workspace Layout Around A Floor-Mounted Metal Lathe For Efficiency And Accessibility?To make your workspace around a metal lathe better, you can organize tools and materials close by. Keep frequently used items on shelves or in drawers nearby. Make sure there’s enough room to walk around safely. You can also use labels to find things quickly. Finally, keep the area clean to avoid accidents.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Setting Up A Floor-Mounted Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions about setting up a floor-mounted metal lathe: 1. What do we need to set up a lathe? 2. How do we level the lathe properly? 3. What safety gear should we wear? 4. What should we check before using it? 5. How do we start the lathe for the first time? These questions will help you learn about using a lathe safely and correctly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please share the specific question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Conditions And Requirements For The Proper Placement Of A Floor Mount Metal Lathe In A Workshop?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To place a floor mount metal lathe properly in your workshop, you need enough space around it. Make sure the floor is strong to hold the weight. Place it on a flat and level surface so it works well. You should have good lighting to see what you’re doing. Lastly, keep it near power sources so you can plug it in easily.”}},{“@type”: “Question”,”name”: “How Do You Level A Floor-Mounted Metal Lathe To Ensure Accurate Machining And Minimize Vibrations During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a floor-mounted metal lathe, first, find a flat surface. You can use a spirit level, which shows if something is straight. Place the lathe on the ground and adjust its feet until the level bubble is in the center. Tighten the feet to keep everything in place. This way, the lathe will work better and make less shaking noise.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Considered When Setting Up A Floor-Mounted Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up a floor-mounted metal lathe, make sure to wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothes so they don’t get caught in the machine. Always check that the lathe is on a stable floor and won’t move. Make sure to keep your hands and tools away from the spinning parts. Finally, read the machine’s manual to understand how to use it safely.”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Necessary For The Proper Installation And Setup Of A Floor-Mounted Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a floor-mounted metal lathe, you need a few important tools and equipment. First, you’ll need wrenches to tighten bolts. A level helps you keep the lathe flat and straight. Using a screwdriver will help with smaller adjustments. Finally, you might need a measuring tape to ensure everything is in the right spot.”}},{“@type”: “Question”,”name”: “How Can You Optimize The Workspace Layout Around A Floor-Mounted Metal Lathe For Efficiency And Accessibility?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your workspace around a metal lathe better, you can organize tools and materials close by. Keep frequently used items on shelves or in drawers nearby. Make sure there’s enough room to walk around safely. You can also use labels to find things quickly. Finally, keep the area clean to avoid accidents.”}}]}