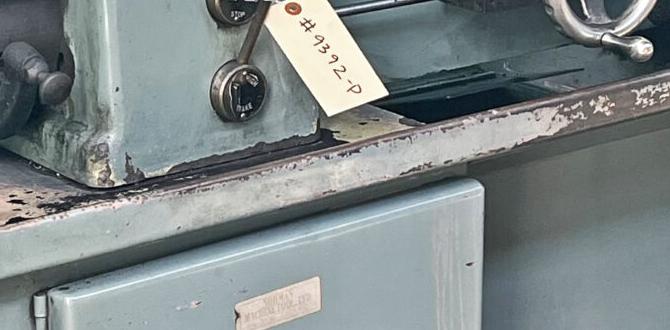

Have you ever wondered how metal pieces are shaped and cut with precision? The magic often lies in a tool called a lathe. Among various lathes, the floor mount metal lathe stands out. It’s sturdy and perfect for heavy-duty work.

One key part of a lathe is the tailstock. This part may look simple, but it plays a big role in making accurate cuts. Why does the tailstock matter so much? Without it, your workpiece would not be secure! Imagine trying to hold a piece of clay while cutting it. It just wouldn’t work, right?

In this article, we will explore the lathe floor mount metal lathe tailstock. Get ready to learn how these tools can help you create amazing things. You might even discover a new passion in metalworking!

Lathe Floor Mount Metal Lathe Tailstock: A Comprehensive Guide

Lathe Floor Mount Metal Lathe Tailstock

The lathe floor mount metal lathe tailstock is crucial for precision work. This tool supports the other end of a workpiece while it spins. Imagine trying to balance a pencil on your finger—that’s tricky! Tailstocks help keep everything steady. They add versatility too, letting you drill holes and perform other tasks. Knowing how to adjust and use the tailstock can enhance your projects. Proper setup ensures accuracy and improves the quality of your work. Choosing the right tailstock makes a big difference.Understanding the Components of a Floor Mount Metal Lathe Tailstock

Definition and function of a tailstock in metal lathes. Key parts of a tailstock: barrel, spindle, handwheel.A tailstock is an essential part of a floor mount metal lathe. It helps to hold tools and supports workpieces securely. Think of it as a trusty sidekick, always there to help you! The tailstock has three key parts: the barrel, which allows for adjustments; the spindle, that holds your tool tight; and the handwheel, which is used for easy movements. Together, they make turning tasks smoother and way more fun!

| Tailstock Parts | Function |

|---|---|

| Barrel | Adjusts height and position |

| Spindle | Holds tools securely |

| Handwheel | Eases movements and adjustments |

Types of Metal Lathe Tailstocks

Difference between fixed and sliding tailstocks. Benefits and limitations of each type.Tailstocks in metal lathes come in two main types: fixed and sliding. Fixed tailstocks stay put like a loyal dog, while sliding tailstocks move with the grace of a dancer. The fixed type provides that rock-solid stability when making precise cuts. However, it lacks flexibility. Sliding tailstocks offer more versatility, but they can introduce some wobble. Think of it as a balance between safety and adventure! Both have their perks and quirks, helping you craft metal wonders.

| Type | Benefits | Limitations |

|---|---|---|

| Fixed | Stability for accurate work | No adjustment; limited flexibility |

| Sliding | Allows for versatile adjustments | Possible wobble during use |

Choosing the Right Floor Mount Metal Lathe Tailstock for Your Needs

Factors to consider: size, weight capacity, precision. Importance of compatibility with your lathe model.Picking the right floor mount metal lathe tailstock can feel tricky, but it doesn’t have to be! First, think about size. A tailstock that’s too big is like trying to fit an elephant in a small car! Next, check the weight capacity. You want it strong enough to handle your projects—no one likes a wobbly workspace! Don’t forget about precision; this means tight tolerances for your tasks. Finally, make sure it matches your lathe model. A mismatched pair is like wearing two different shoes—definitely not stylish!

| Factor | Importance |

|---|---|

| Size | Must fit your workspace |

| Weight Capacity | Supports heavy projects |

| Precision | Ensures accurate results |

| Compatibility | Works with your lathe model |

Installation and Setup of a Floor Mount Metal Lathe Tailstock

Stepbystep installation guide. Common mistakes to avoid during setup.Setting up your metal lathe tailstock can feel like a quest to assemble an IKEA dresser without instructions. But fear not! Follow these simple steps for success. Start by placing the tailstock on the lathe bed, ensuring it’s aligned properly. Tighten the screws like you’re sealing a jar of pickles—firm but not excessive. Don’t forget to level it! Avoid common mistakes like forgetting to tighten everything; you don’t want it wobbling like a jelly on a trampoline. Here’s a quick table summarizing the do’s and don’ts:

| Do’s | Don’ts |

|---|---|

| Align the tailstock properly | Ignore loose screws |

| Level before use | Skip checking for wobble |

| Use proper tools | Force things into place |

Remember, the key is patience and attention to detail. A little care now can save you from disaster later. And with a wink and a smile, you’ll be using your lathe like a pro!

Maintenance Tips for Longevity of Tailstocks

Importance of regular cleaning and lubrication. Signs of wear and when to replace components.Keeping your tailstock in good shape is just like brushing your teeth: it’s all about routine! Regular cleaning and lubrication help it run smoothly and last longer. Check for dust and grime, just like you check for spinach in your teeth. Watch for signs of wear, like strange noises or loose movements. If it acts tired, it might need a new part. Don’t wait until it’s too late; replacing components at the right time saves you from bigger problems later. Here’s a quick guide:

| Signs of Wear | Action Needed |

|---|---|

| Unusual Noise | Check lubrication |

| Loose Tailstock | Tighten or replace components |

| Inconsistent Movement | Inspect and clean parts |

Common Issues and Troubleshooting for Tailstocks

Frequent problems users encounter. Solutions and preventative measures.Many users face problems with tailstocks on their metal lathes. Common issues include misalignment, difficulty in moving the tailstock, and wear on components. Solutions can often be simple. Here are some ways to fix and prevent problems:

- Check alignment: Regularly ensure the tailstock aligns correctly on the bed.

- Lubricate parts: Keep the tailstock mechanism well-greased to avoid stiffness.

- Inspect for wear: Look for worn parts and replace them when needed.

What is a common problem with lathe tailstocks?

Misalignment is a typical issue which can lead to inaccurate cuts. Adjusting the position helps fix this.

Using the Tailstock Effectively in Machining Operations

Techniques for precise alignment and setup. Tips for enhancing productivity with the tailstock.The tailstock is your best buddy for keeping things straight and balanced in machining. First, check your tailstock alignment with the lathe. It should be as straight as a ruler! If it’s off, your workpiece might go on a wild adventure. Next, always tighten your setup. A loose tailstock is like a wobbly chair—no one wants that! For productivity, try organizing your workspace. Less clutter means less chaos. Remember, a well-set tailstock is like a superhero cape—it helps you get the job done!

| Technique | Description |

|---|---|

| Alignment Check | Ensure the tailstock is aligned with the lathe for better precision. |

| Tightening | Always tighten your tailstock to avoid wobbly setups. |

| Workspace Organization | A tidy space boosts productivity and minimizes mistakes. |

Conclusion

In summary, a lathe floor mount metal lathe tailstock is essential for stability and precision. It helps you support long materials while you work. By understanding how to use it properly, you can improve your projects. We encourage you to explore more about lathe techniques and practice using the tailstock for better results in your work. Happy crafting!FAQs

Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Tailstock:What is a tailstock on a lathe? A tailstock is a part of a lathe that helps you hold pieces while you work on them. It sits on the side opposite the machine’s spinning part. You can adjust it to fit different sizes. This helps you to make safe and accurate cuts. It’s like a helper that keeps things steady!

Sure! Please provide the question you want me to answer.

What Are The Primary Functions Of A Tailstock In A Metal Lathe?The tailstock on a metal lathe helps support long pieces of metal. You can use it to hold tools, like drills. It also helps to keep things stable while spinning. This way, we can make accurate shapes and cuts.

How Does The Height And Alignment Of The Tailstock Affect The Accuracy Of Machining Operations?The tailstock holds tools or parts in place while we work. If it’s too high or low, things can wobble. This wobbling makes cuts less accurate. When the tailstock is lined up correctly, we get better and smoother results. So, we need to check it before starting!

What Are The Differences Between A Fixed And Adjustable Tailstock On A Floor Mount Metal Lathe?A fixed tailstock cannot move. It stays in one spot on the metal lathe. An adjustable tailstock can slide back and forth. This lets you change how far it is from the other parts. You can fit different sizes of pieces better with an adjustable tailstock.

What Types Of Tools And Accessories Can Be Attached To The Tailstock For Various Machining Tasks?You can attach different tools to the tailstock of a machine. For example, you can use a drill chuck. This helps hold drill bits for boring holes. You can also attach a live center, which spins while holding the end of a piece, making it neat. Lastly, a steady rest can be used to support long pieces and keep them steady while you work.

How Can One Properly Maintain And Adjust A Tailstock To Ensure Optimal Performance And Longevity?To keep a tailstock working well, you should clean it regularly. Check for rust and wipe it down with oil to keep it smooth. Make sure it fits tightly on the machine by adjusting the screws. If it moves too easily, it might need tightening. Always read the machine’s manual for specific tips!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Tailstock:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “What is a tailstock on a lathe? A tailstock is a part of a lathe that helps you hold pieces while you work on them. It sits on the side opposite the machine’s spinning part. You can adjust it to fit different sizes. This helps you to make safe and accurate cuts. It’s like a helper that keeps things steady!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Functions Of A Tailstock In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tailstock on a metal lathe helps support long pieces of metal. You can use it to hold tools, like drills. It also helps to keep things stable while spinning. This way, we can make accurate shapes and cuts.”}},{“@type”: “Question”,”name”: “How Does The Height And Alignment Of The Tailstock Affect The Accuracy Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tailstock holds tools or parts in place while we work. If it’s too high or low, things can wobble. This wobbling makes cuts less accurate. When the tailstock is lined up correctly, we get better and smoother results. So, we need to check it before starting!”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Fixed And Adjustable Tailstock On A Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A fixed tailstock cannot move. It stays in one spot on the metal lathe. An adjustable tailstock can slide back and forth. This lets you change how far it is from the other parts. You can fit different sizes of pieces better with an adjustable tailstock.”}},{“@type”: “Question”,”name”: “What Types Of Tools And Accessories Can Be Attached To The Tailstock For Various Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can attach different tools to the tailstock of a machine. For example, you can use a drill chuck. This helps hold drill bits for boring holes. You can also attach a live center, which spins while holding the end of a piece, making it neat. Lastly, a steady rest can be used to support long pieces and keep them steady while you work.”}},{“@type”: “Question”,”name”: “How Can One Properly Maintain And Adjust A Tailstock To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a tailstock working well, you should clean it regularly. Check for rust and wipe it down with oil to keep it smooth. Make sure it fits tightly on the machine by adjusting the screws. If it moves too easily, it might need tightening. Always read the machine’s manual for specific tips!”}}]}