Imagine standing in a workshop filled with tools and machines. The sound of metal grinding catches your ear. Have you ever wondered how that metal gets shaped? A lathe is a magical tool. It spins metal and helps create beautiful designs. One important type is the floor mount metal lathe.

But what makes a floor mount metal lathe special? Unlike smaller versions, this one stands tall and strong. It gives you more space to work and allows for bigger pieces. With a floor mount metal lathe, you can even do something super cool—thread cutting! This technique helps you create threads on metal. Threads are not just fun; they are useful.

Did you know that ancient craftsmen used similar methods thousands of years ago? They shaped metal by hand, using tools we can’t even imagine today. Now, thanks to modern designs, you can easily create exact shapes and sizes. Isn’t that amazing? In this article, we will explore the world of floor mount metal lathes and thread cutting. You are about to uncover the secrets of this fascinating tool!

Lathe Floor Mount Metal Lathe Thread Cutting: A Guide

Understanding Lathe Floor Mount Metal Lathe Thread Cutting

Lathe floor mount metal lathes are essential tools for many craftsmen. They allow for accurate cutting of threads on metal pieces. Thread cutting helps create strong connections in various projects. Did you know that with the right lathe, you can easily make screws and bolts? This skill opens doors to endless possibilities in metalworking. Learning to use a lathe effectively can boost your DIY projects. Imagine creating custom parts with ease and precision!Understanding Lathe Machines

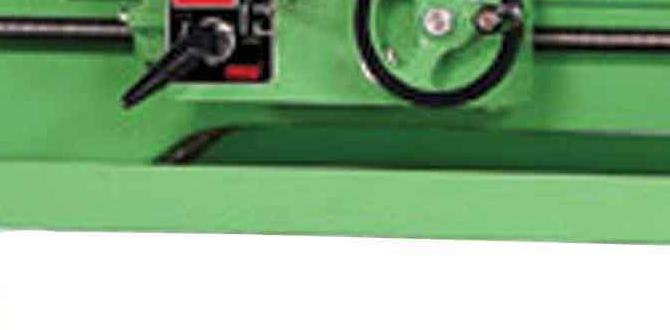

Definition and types of lathe machines. Importance of floor mount designs in metalworking.Lathe machines are tools that shape materials by rotating them against a cutting tool. There are different types, including floor mount, benchtop, and CNC lathes. Floor mount designs are popular in metalworking. They provide excellent stability and can handle heavier materials. This allows better precision in projects such as thread cutting. With their sturdy base, users can work safely.

What types of lathe machines are there?

Types of lathe machines include:

- Floor Mount Lathes

- Benchtop Lathes

- CNC Lathes

Why are floor mount lathes important?

Floor mount lathes offer stability and strength. This helps in making precise cuts. With these machines, metalworkers can feel confident and safe while working. They prevent wobbling and increase accuracy.

Key Features of Floor Mount Metal Lathes

Advantages of floor mount over other lathe types. Essential specifications for effective thread cutting.Floor mount lathes are like the sturdy friends of the metalworking world. They stand firm and offer many advantages over other types. For starters, they usually have a bigger working area. This means you can create larger pieces without hopping around! Plus, they provide better stability for precision work. For successful thread cutting, look for specifications like strong spindle motors and adjustable speed controls. These features make smooth and easy cuts. Remember, happy lathe, happy you!

| Feature | Benefit |

|---|---|

| Stability | Less vibration, better precision! |

| Larger workspace | Create bigger projects! |

| Adjustable speeds | Perfect for different materials! |

Thread Cutting Basics

Explanation of thread cutting and its applications. Different types of threads and their uses in metal fabrication.Thread cutting is like putting a twist on things—literally! It helps create grooves in metal for screws, bolts, and fittings. This process is super important in metal fabrication. Imagine trying to hold two pieces of metal together without threads; that could lead to a very clumsy situation. There are many thread types, like national coarse and metric, each with its own special job. Here’s a quick look:

| Thread Type | Application |

|---|---|

| National Coarse | General use in wood and light metal |

| Metric | Used for precise engineering tasks |

| Tapered Threads | Common in plumbing to prevent leaks |

Each thread has a purpose, so choosing the right one can save you from falling apart—literally!

Setup and Calibration of Floor Mount Metal Lathes

Stepbystep guide to setting up the lathe for thread cutting. Importance of calibration for precision work.Setting up a lathe for thread cutting is a fun task! First, find a flat surface for stability. Next, secure the lathe. Follow these steps:

- Check the power supply.

- Attach the tool holder.

- Adjust the tailstock and carriage.

Calibration is key for precision. It helps create accurate threads. A small mistake can lead to big errors. So, take your time! Ensure everything is aligned correctly.

Why is calibration important for thread cutting?

Calibration ensures your lathe cuts threads accurately and consistently. This means better quality and less waste. By checking your settings, you can avoid mistakes and get great results every time.

Techniques for Precision Thread Cutting

Detailed techniques for achieving accurate threads. Tips for common threading challenges and how to overcome them.To achieve precise thread cutting on your lathe, focus on these techniques. Start by choosing the right tool and speed. Ensure your lathe is set up correctly. Monitor your feed rate carefully. Pay attention to the cutting depth to prevent errors. If you face challenges like chatter or uneven threads, try these tips:

- Keep tools sharp.

- Reduce speed if vibration occurs.

- Check and correct alignment.

- Use proper lubrication.

With practice, you’ll master these skills and produce perfect threads every time!

What are common threading challenges?

Common threading challenges include chatter, uneven threads, and tool wear. Adjusting speeds and maintaining tools can solve these issues easily.

Maintenance and Care for Longevity

Regular maintenance practices for floor mount lathes. Signs of wear and how to address them.Taking care of your lathe is important for long use. Here are some regular maintenance practices:

- Keep the machine clean and free from dust.

- Check the oil levels often and change it when dirty.

- Tighten loose parts to avoid accidents.

- Inspect belts and gears for any signs of wear.

Look for signs that your lathe needs attention. If it makes strange noises, vibrates too much, or doesn’t work smoothly, it might be time to act. React quickly to these signs to keep your lathe safe and effective.

What are common signs of wear on a lathe?

Common signs include unusual noises, rough operation, and loose parts. If you notice these, it’s best to address the issue right away.

Comparative Analysis with Other Thread Cutting Methods

Advantages and disadvantages of using a floor mount lathe versus other methods. Case studies or examples from industry professionals.Using a floor mount lathe for thread cutting has its perks and quirks. One big advantage is its stability, which helps create clean, accurate threads. Other methods might wobble and cause chaos! However, it takes up more space and can be costly. For example, many professionals in the automotive industry prefer floor mount lathes for precision. They say, *”It’s like having a trusty sidekick that always delivers.”* Let’s compare the pros and cons:

| Method | Advantages | Disadvantages |

|---|---|---|

| Floor Mount Lathe | Stable and precise | Takes up space, more expensive |

| Portable Machines | Space-saving, often cheaper | Less stable, may cause errors |

| Manual Methods | Low cost | Requires skill, more time-consuming |

In short, a floor mount lathe can be your best friend or a fancy doorstop! Choose wisely based on your needs.

Conclusion

In summary, floor mount metal lathes are great for thread cutting. They help you create precise threads on metal pieces. Remember, practice makes perfect—you’ll improve with experience. Always prioritize safety when using any lathe. If you want to learn more, explore videos or tutorials online. Dive into this hands-on hobby, and enjoy your metalworking projects!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Thread Cutting:Sure! A floor mount metal lathe is a tool that helps you shape metal. When we talk about thread cutting, we mean making grooves in the metal so it can screw together. This tool can make threads for things like pipes or bolts. Using a lathe is fun and lets you create cool projects. Just remember to follow safety rules!

Sure! Please give me the question you would like me to answer.

What Are The Essential Components Of A Floor Mount Metal Lathe Used For Thread Cutting?A floor mount metal lathe has several important parts for thread cutting. First, we have the bed, which holds everything steady. Next, there’s the headstock, where we put the metal piece to work on. The tailstock helps support the other end of the metal. Finally, the carriage moves the cutting tool along the metal to make the threads.

How Do You Set The Correct Threading Pitch On A Lathe For Accurate Thread Cutting?To set the correct threading pitch on a lathe, you first need to find the right gear. This gear helps the machine move the tool correctly. Next, you look at the thread pitch you want, like how far apart the threads are. Finally, you adjust the machine’s settings to match that number. Now you’re ready to cut threads accurately!

What Safety Precautions Should Be Observed While Performing Thread Cutting On A Floor Mount Lathe?When you use a floor mount lathe to cut threads, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight-fitting clothes to avoid getting caught in the machine. Make sure the area is clean and free of any tools or clutter. Always use the right tools and hold them carefully. Finally, never reach into the machine while it’s running.

How Can You Troubleshoot Common Issues Encountered During The Thread Cutting Process On A Lathe?To fix problems when cutting threads on a lathe, first check your tools. Make sure they are sharp and clean. If threads are too loose or too tight, adjust the speed carefully. If the machine vibrates, make sure everything is tight and secure. Lastly, measure your threads often to catch any mistakes early.

What Types Of Threading Tools And Inserts Are Recommended For Floor Mount Metal Lathes When Cutting Different Materials?For floor mount metal lathes, we can use different tools for threading. HSS (high-speed steel) tools are great for softer metals like aluminum. If you’re cutting tougher metals like steel, carbide inserts work better. These inserts last longer and cut more smoothly. Always choose the right tool for the material you work with!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Thread Cutting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A floor mount metal lathe is a tool that helps you shape metal. When we talk about thread cutting, we mean making grooves in the metal so it can screw together. This tool can make threads for things like pipes or bolts. Using a lathe is fun and lets you create cool projects. Just remember to follow safety rules!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Of A Floor Mount Metal Lathe Used For Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A floor mount metal lathe has several important parts for thread cutting. First, we have the bed, which holds everything steady. Next, there’s the headstock, where we put the metal piece to work on. The tailstock helps support the other end of the metal. Finally, the carriage moves the cutting tool along the metal to make the threads.”}},{“@type”: “Question”,”name”: “How Do You Set The Correct Threading Pitch On A Lathe For Accurate Thread Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set the correct threading pitch on a lathe, you first need to find the right gear. This gear helps the machine move the tool correctly. Next, you look at the thread pitch you want, like how far apart the threads are. Finally, you adjust the machine’s settings to match that number. Now you’re ready to cut threads accurately!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Observed While Performing Thread Cutting On A Floor Mount Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a floor mount lathe to cut threads, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight-fitting clothes to avoid getting caught in the machine. Make sure the area is clean and free of any tools or clutter. Always use the right tools and hold them carefully. Finally, never reach into the machine while it’s running.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues Encountered During The Thread Cutting Process On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems when cutting threads on a lathe, first check your tools. Make sure they are sharp and clean. If threads are too loose or too tight, adjust the speed carefully. If the machine vibrates, make sure everything is tight and secure. Lastly, measure your threads often to catch any mistakes early.”}},{“@type”: “Question”,”name”: “What Types Of Threading Tools And Inserts Are Recommended For Floor Mount Metal Lathes When Cutting Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For floor mount metal lathes, we can use different tools for threading. HSS (high-speed steel) tools are great for softer metals like aluminum. If you’re cutting tougher metals like steel, carbide inserts work better. These inserts last longer and cut more smoothly. Always choose the right tool for the material you work with!”}}]}