Have you ever wondered how a metal lathe works? Understanding the lathe gear ratio can make a big difference. The right gear ratio helps you shape metal with precision. It’s like having a magic tool that turns a simple piece of metal into something amazing.

Many people enjoy using lathes to create all sorts of items. From toys to tools, the possibilities are endless. However, choosing the right lathe gear ratio can be tricky. Why is it important? Because the best metal lathe for you depends on what you want to create!

Did you know that a small change in gear ratio can change how fast your lathe turns? This can lead to better finishes and smoother cuts. Imagine making a perfectly shaped part just by adjusting a few numbers! Learning about lathe gear ratios can unlock a whole new world of creativity.

In this article, we will explore how to find the best metal lathe for your needs. We’ll dive into gear ratios, what they do, and how they can improve your work. Get ready to discover the secrets of metal lathes and gear ratios!

Lathe Gear Ratio: Best Metal Lathe For Precision Machining

Understanding Lathe Gear Ratio for the Best Metal Lathe

Choosing the right lathe gear ratio can greatly improve your metalworking projects. A proper gear ratio helps control the speed and torque of the lathe, allowing for precise cuts. This means you can work with different materials, from soft aluminum to hard steel. Did you know that a higher gear ratio increases speed but lowers torque? Finding the balance that fits your needs can make all the difference. Mastering this can lead to amazing creations!What is a Lathe Gear Ratio?

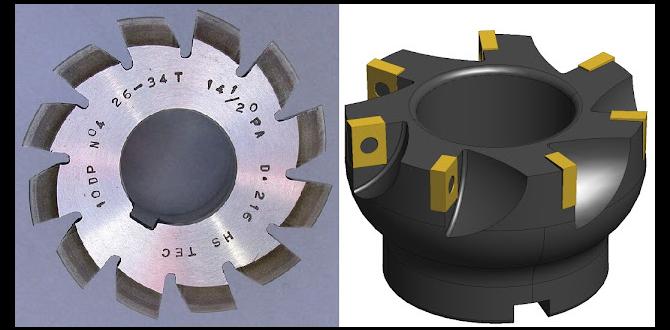

Definition of gear ratio in the context of lathes. Importance of gear ratios in metalworking.A lathe gear ratio shows how many times the lathe spins its gears compared to the workpiece. This ratio is critical in metalworking. It lets you choose the right speed for cutting different materials.

- Higher ratios mean faster workpiece speeds.

- Lower ratios are better for detailed cuts.

This balance helps create smooth and precise parts. Understanding gear ratios can make your work easier and more efficient.

Why are gear ratios important for metalworking?

Gear ratios influence cutting speed and power. They help you use the lathe effectively. Misusing them can lead to mistakes or damage.

How to Calculate Gear Ratios for Your Lathe

Stepbystep guide to calculating gear ratios. Tools and formulas required for accurate calculations.Calculating gear ratios for your lathe can be fun! First, grab a calculator—your trusty sidekick. To find the ratio, use this formula: Gear Ratio = Number of Teeth on Driven Gear / Number of Teeth on Driver Gear. If you have gears with 20 teeth and 10 teeth, your gear ratio is 2:1. This means the driven gear spins twice for every turn of the driver. Simple, right? Here’s a quick table for reference:

| Driven Gear Teeth | Driver Gear Teeth | Gear Ratio |

|---|---|---|

| 20 | 10 | 2:1 |

| 30 | 15 | 2:1 |

| 40 | 10 | 4:1 |

With this info, you can build the best metal lathe without getting lost in the numbers. Remember, math can be tricky, but it’s also like magic—only with gears!

Best Gear Ratios for Different Types of Metalworking Projects

Recommended gear ratios for precision machining. Optimal gear ratios for heavyduty applications.Choosing the right gear ratio makes all the difference in metalworking. For precision machining, a gear ratio between 2:1 and 4:1 is best. This helps achieve fine details. For heavy-duty applications, consider a ratio of 4:1 to 6:1. This choice provides strength for tough materials. Here’s a quick summary:

- Precision Machining: 2:1 to 4:1

- Heavy-Duty Applications: 4:1 to 6:1

Using the correct ratio can lead to better work. It saves time and ensures great results!

What gear ratios are best for metalworking?

Precision machining works best with 2:1 to 4:1 gear ratios, while heavy-duty tasks benefit from a 4:1 to 6:1 ratio.

Factors to Consider When Choosing a Gear Ratio

Influence of material type and thickness. Effects of speed and power requirements on gear selection.Choosing the right gear ratio for your lathe is a bit like picking the perfect pizza toppings. You need to know what material you are cutting! Thicker materials often need lower gear ratios for more power. In contrast, lighter materials can handle higher speeds. Don’t forget about speed and power requirements! If you push too fast, your lathe might just throw a tantrum. Balancing these factors will help you make a smarter choice.

| Material Type | Recommended Gear Ratio |

|---|---|

| Wood | High Speed |

| Aluminum | Moderate Speed |

| Steel | Low Speed, High Power |

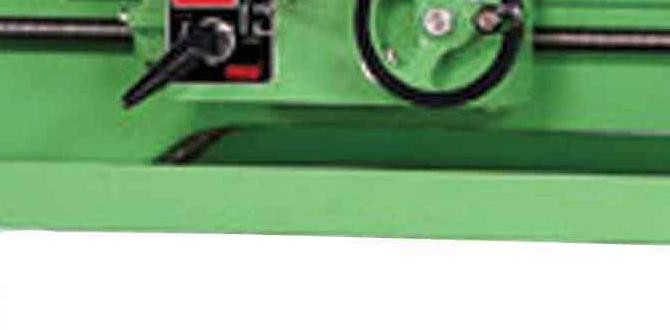

Top Recommended Metal Lathes with Ideal Gear Ratios

Review of popular lathe models and their gear ratios. Comparison of features, benefits, and performance.Choosing the right metal lathe can feel like hunting for a needle in a haystack. Luckily, there are some standout models with gear ratios that can make turning metal a breeze. Popular lathes like the Grizzly G0602 and Jet JWL-1442 have gears that let you control speed with ease. Better gears mean better results, folks! Check out the table below for a quick comparison of features and performance.

| Model | Gear Ratio | Max RPM | Benefits |

|---|---|---|---|

| Grizzly G0602 | 10:1 | 1440 | Stable performance, easy to handle |

| Jet JWL-1442 | 12:1 | 3800 | Fast speeds, smooth operation |

These lathes are user-friendly and offer great features. You’ll be a metal wizard in no time, just don’t forget your safety glasses!

Maintenance Tips for Gear Ratio Systems

Best practices for maintaining lathe gear systems. Signs of wear and tear to watch for in gear setups.Keeping gear ratio systems in good shape is important. Here are some best practices for maintenance:

- Check lubrication regularly. Proper oil keeps gears running smoothly.

- Inspect gears for chips or cracks. These can lead to bigger problems.

- Listen for unusual noises. Grinding sounds often signal wear.

- Clean the area around the gears. Dirt can cause parts to wear out faster.

- Replace worn gears promptly. Ignoring them can lead to system failure.

Keeping an eye on these details helps your lathe last longer. A well-maintained system runs better and produces higher quality work.

What are signs of wear in gear setups?

Look for these key signs:

- Uneven wear on the teeth.

- Difficulty in rotation.

- Excessive vibration during operation.

- Poor alignment of gears.

Recognizing these signs early can prevent costly repairs.

Conclusion

In conclusion, understanding lathe gear ratios helps you choose the best metal lathe for your needs. A good gear ratio improves precision and efficiency. We encourage you to explore different lathe models and their gear ratios. This knowledge will help you make informed decisions and enhance your metalworking skills. Keep learning and happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios For The Best Metal Lathe:Sure! Here are five questions about lathe gear ratios for the best metal lathe: 1. What is a lathe gear ratio? A lathe gear ratio tells us how fast the lathe spins. It shows the relationship between the gears. 2. How do gear ratios affect speed? A higher gear ratio means the lathe spins faster. A lower ratio means a slower speed. 3. Why are different ratios important? Different ratios help with various tasks. You might need speed for some jobs and power for others. 4. How do you choose the right ratio? To choose, think about what you will make. Different projects need different speeds and powers. 5. Can I change gear ratios on my lathe? Yes, many lathes let you change ratios. This helps you get the best results for each project.

Sure! Please ask your question, and I’ll help you with a short answer.

What Factors Should Be Considered When Determining The Ideal Gear Ratio For A Metal Lathe?When choosing the best gear ratio for a metal lathe, think about what you’re making. Consider the material you will cut. Hard materials need slower speeds for safety and accuracy. Also, think about how smooth you want the machine to run. Finally, consider the size of the pieces you are working on. These choices will help you find the right gear ratio.

How Does The Gear Ratio Affect The Cutting Speed And Torque In A Metal Lathe?The gear ratio in a metal lathe changes how fast the cutting tool moves and how strong it is. A high gear ratio makes the tool go faster, which helps cut through metal quickly. However, it gives less strength or torque. On the other hand, a low gear ratio means more strength, helping to cut tougher metal. So, you choose the gear ratio based on whether you need speed or strength for your work.

What Are The Advantages And Disadvantages Of Variable Gear Ratios In Metal Lathes?Variable gear ratios in metal lathes let you change how fast the machine spins. The good part is that you can adjust the speed to fit different jobs. This makes it easier to work on different materials. However, the downside is that it can be more complex, which might make it harder to use for some people. Sometimes, this complexity can lead to problems if parts wear out or break.

How Can A Lathe Operator Adjust Or Change Gear Ratios To Optimize Performance For Different Materials?To change gear ratios on a lathe, you first stop the machine. Then, you can switch the gears to a different size. This helps the lathe turn faster or slower, depending on what material you are working with. For soft materials, use a higher gear for speed. For hard materials, use a lower gear for more power and control.

Which Metal Lathe Models Are Known For Having The Best Gear Ratio Options For Precision Machining?Some metal lathes are great for precision work. Popular models include the South Bend SB1002 and Grizzly G0602. These machines have different gear settings. This helps you make very accurate pieces. You can choose the right speed for your project.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios For The Best Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe gear ratios for the best metal lathe: 1. What is a lathe gear ratio? A lathe gear ratio tells us how fast the lathe spins. It shows the relationship between the gears. 2. How do gear ratios affect speed? A higher gear ratio means the lathe spins faster. A lower ratio means a slower speed. 3. Why are different ratios important? Different ratios help with various tasks. You might need speed for some jobs and power for others. 4. How do you choose the right ratio? To choose, think about what you will make. Different projects need different speeds and powers. 5. Can I change gear ratios on my lathe? Yes, many lathes let you change ratios. This helps you get the best results for each project.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll help you with a short answer.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Determining The Ideal Gear Ratio For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the best gear ratio for a metal lathe, think about what you’re making. Consider the material you will cut. Hard materials need slower speeds for safety and accuracy. Also, think about how smooth you want the machine to run. Finally, consider the size of the pieces you are working on. These choices will help you find the right gear ratio.”}},{“@type”: “Question”,”name”: “How Does The Gear Ratio Affect The Cutting Speed And Torque In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio in a metal lathe changes how fast the cutting tool moves and how strong it is. A high gear ratio makes the tool go faster, which helps cut through metal quickly. However, it gives less strength or torque. On the other hand, a low gear ratio means more strength, helping to cut tougher metal. So, you choose the gear ratio based on whether you need speed or strength for your work.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Variable Gear Ratios In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable gear ratios in metal lathes let you change how fast the machine spins. The good part is that you can adjust the speed to fit different jobs. This makes it easier to work on different materials. However, the downside is that it can be more complex, which might make it harder to use for some people. Sometimes, this complexity can lead to problems if parts wear out or break.”}},{“@type”: “Question”,”name”: “How Can A Lathe Operator Adjust Or Change Gear Ratios To Optimize Performance For Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change gear ratios on a lathe, you first stop the machine. Then, you can switch the gears to a different size. This helps the lathe turn faster or slower, depending on what material you are working with. For soft materials, use a higher gear for speed. For hard materials, use a lower gear for more power and control.”}},{“@type”: “Question”,”name”: “Which Metal Lathe Models Are Known For Having The Best Gear Ratio Options For Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some metal lathes are great for precision work. Popular models include the South Bend SB1002 and Grizzly G0602. These machines have different gear settings. This helps you make very accurate pieces. You can choose the right speed for your project.”}}]}