Have you ever wondered how machines make perfect shapes from metal? One secret lies in something called the lathe gear ratio. This nifty term sounds complicated, but it’s essential for anyone interested in metal lathe automation.

Imagine a robot whirling around, shaping metal into cool designs. It’s not just magic; it’s science! The gear ratio helps machines spin at the right speed. This means they can work faster and more accurately.

Did you know that the right gear ratio can change how well a metal lathe works? Too high or too low can lead to mistakes. But with precise automation, these machines can create amazing products without tiring.

Curious to learn more about how gear ratios influence automation? Strap in as we explore this fascinating world together! You might just discover how these tools shape our everyday lives.

Understanding Lathe Gear Ratio In Metal Lathe Automation

Lathe Gear Ratio and Metal Lathe Automation

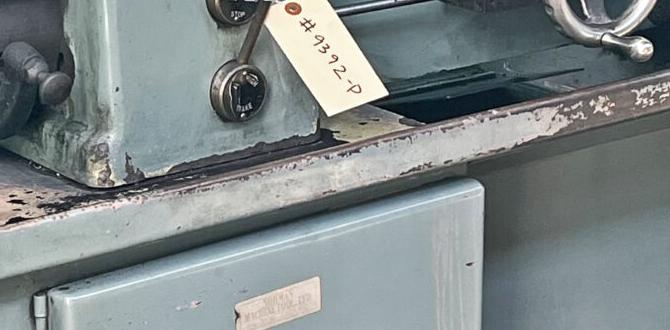

Understanding lathe gear ratios is important in metal lathe automation. A gear ratio determines how fast the lathe spindle turns. This impacts the precision and efficiency of machining tasks. When automating, choosing the right gear ratio helps maintain speed while improving performance. Curious about how better ratios can enhance your projects? Many find that optimal settings save time and reduce errors. Exploring these aspects can make any metalworker more skilled and effective in their craft.What is Lathe Gear Ratio?

Definition of gear ratio in metal lathes. Importance of gear ratio in machining processes.Ever wondered what gear ratio means? It’s like a secret code for metal lathes! The gear ratio tells you how fast one gear turns compared to another. This is super important in machining because it helps control speed and power during work. The right ratio can make cutting materials easier and smoother. Without it, you might end up with a messy project. Think of it as the difference between spinning a top gently or making it spin like a jet engine!

| Gear Ratio | Speed |

|---|---|

| 1:1 | Same speed |

| 2:1 | Double speed |

| 1:2 | Half speed |

In short, understanding gear ratios is essential for getting things just right in machining. Think of it like picking a tune for your dance moves; the right beat keeps everything on track!

Calculating Gear Ratios

Stepbystep guide on how to calculate gear ratios. Common formulas used in the process.To find the gear ratio, follow these simple steps. First, identify the number of teeth on each gear. Next, use the formula: Gear Ratio = Teeth on Driven Gear / Teeth on Driving Gear. For example, if the driving gear has 10 teeth and the driven gear has 20, the gear ratio is 2:1. This means the driving gear turns twice for every turn of the driven gear. Remember, understanding gear ratios helps you improve your metal lathe automation.

How do you calculate gear ratios?

To calculate gear ratios, divide the number of teeth on the driven gear by the number of teeth on the driving gear.- Count the teeth on each gear.

- Use the formula mentioned above.

- Interpret the result to see how gears work together.

The Role of Gear Ratios in Automation

How gear ratios affect automation efficiency. Benefits of precise gear ratio settings in automated lathes.Gear ratios play a key role in how automation works. They help machines run more smoothly. With the right gear ratio, a lathe can operate faster and more accurately. Here are some benefits:

- Increased speed

- Better precision

- Less wear on parts

- Improved energy efficiency

Setting precise gear ratios allows automated lathes to complete tasks effectively. This means they do not waste time or energy. For example, engineers say that using the correct gear ratio can boost efficiency by over 30%. This helps save money and resources.

How do gear ratios affect automation efficiency?

Gear ratios directly influence automation efficiency by maximizing speed while maintaining control. Machines can function faster without compromising performance. A well-calibrated gear ratio leads to:

Benefits:

- Faster production times.

- Greater consistency in outputs.

- Reduced risk of errors during operation.

Adjusting Gear Ratios for Optimal Performance

Techniques for adjusting gear ratios in lathes. Impacts of adjustments on machining quality and speed.Adjusting gear ratios can feel like trying to solve a riddle while juggling. But don’t worry, it’s easier than it sounds! First, you can use simple techniques like swapping gears or tweaking your belt tension. These changes can seriously boost machining quality. If the gears work well together, you cut faster and smoother. Remember, the right ratio is like finding the perfect pizza topping—essential for satisfying results!

| Technique | Impact on Machining |

|---|---|

| Gear Swapping | Improves speed and accuracy |

| Belt Adjustment | Reduces vibration and noise |

With the right adjustments, you can keep that lathe running smoother than a buttered slide! Just remember to test and fine-tune your settings for the best results. Happy machining!

Future Trends in Lathe Gear Automation

Innovations in gear design and automation technology. Predictions for the evolution of gear ratios in lathes.The world of lathe gear automation is getting exciting! New gear designs are popping up like popcorn at a movie. These innovations make machines more efficient and easy to use. Soon, we might see gear ratios that adapt automatically, much like how your favorite snack seems to magically refill when you’re watching TV.

Experts predict that future lathes will have smarter gear ratios. This means they’ll adjust themselves based on the task at hand. It’s like having a super-smart buddy helping you out in the workshop!

| Innovation | Description |

|---|---|

| Adaptive Gearing | Gears change ratio based on material and speed. |

| Smart Controls | Automated systems that learn from usage. |

With these clever upgrades, lathes will soon work harder and faster, leaving more time for you to enjoy lunch—or maybe just a quick nap!

Case Studies of Gear Ratio Optimization

Realworld examples of efficient gear ratio setups. Lessons learned from successful lathe automation projects.Many real-world cases show how proper gear ratio setups can boost performance. For example, a company changed their lathe gear ratios. This change made their machines work faster and smoother. They noticed less wear and tear too. Key lessons from successful lathe automation projects include:

- Right gear ratios save time.

- Automation reduces errors.

- Planning is key to success.

These examples teach us that small adjustments can lead to big improvements.

How do gear ratios affect lathe performance?

Gear ratios affect torque and speed. A high gear ratio allows for greater speed, while a low gear ratio increases torque. This balance is essential in lathe operations.

Conclusion

In summary, understanding lathe gear ratios helps you control cutting speeds and improve accuracy. Automation can make your metal lathe faster and easier to use. With these tools, you can create better projects. We encourage you to explore more about lathe gear ratios and automation. Try experimenting with your lathe to see what you can create!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Automation:Sure! A lathe is a machine that shapes metal. The gear ratio helps us control how fast the lathe spins. When we change the gears, we can make different shapes. Automation means using machines to do things on their own. This makes work faster and easier for us!

Sure! Please let me know what question you would like me to answer, and I will be happy to help.

How Does The Gear Ratio Of A Metal Lathe Impact Its Cutting Speed And Torque During Automated Operations?The gear ratio of a metal lathe changes how fast it spins and how much force it has. A higher gear ratio means faster cutting speed but less power. When we lower the gear ratio, we get more torque, which helps cut harder materials. This is important for making sure our projects turn out well. So, we can adjust the gear ratio to do different types of jobs.

What Are The Advantages Of Using Automated Gear Ratio Adjustments In Metal Lathes For Various Machining Tasks?Automated gear ratio adjustments in metal lathes are really helpful. They let you change speeds quickly and easily. This means you can work on different materials without stopping much. It makes the work faster and more accurate. Plus, it helps keep everything running smoothly!

How Can Servo Motors Be Integrated Into A Metal Lathe’S Gear System To Enhance Precision And Automation?We can add servo motors to a metal lathe’s gear system to make it work better. Servo motors help the lathe turn exactly how we want it to. This means our pieces will be made more accurately and neatly. With these motors, we can also set new tasks for the lathe to do automatically, helping us a lot!

What Factors Should Be Considered When Selecting The Appropriate Gear Ratio For A Specific Metalworking Application In An Automated Lathe System?When choosing the right gear ratio for a lathe, think about the material you’re working with. Different metals need different speeds to cut well. Also, consider how much power you have. More power can help you cut faster. Lastly, think about the detail you want. For fine details, a slower speed might work better.

How Do Modern Control Systems For Metal Lathes Utilize Gear Ratios To Optimize Performance And Efficiency In Automated Machining Processes?Modern control systems for metal lathes use gear ratios to help machines work better and faster. Gear ratios are like settings that control how quickly a tool turns. With the right gear ratio, the lathe can cut materials smoothly without wasting energy. This makes the lathe more efficient and helps us create better parts. So, by adjusting these ratios, we ensure machines do their best job.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal. The gear ratio helps us control how fast the lathe spins. When we change the gears, we can make different shapes. Automation means using machines to do things on their own. This makes work faster and easier for us!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please let me know what question you would like me to answer, and I will be happy to help.”}},{“@type”: “Question”,”name”: “How Does The Gear Ratio Of A Metal Lathe Impact Its Cutting Speed And Torque During Automated Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio of a metal lathe changes how fast it spins and how much force it has. A higher gear ratio means faster cutting speed but less power. When we lower the gear ratio, we get more torque, which helps cut harder materials. This is important for making sure our projects turn out well. So, we can adjust the gear ratio to do different types of jobs.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using Automated Gear Ratio Adjustments In Metal Lathes For Various Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automated gear ratio adjustments in metal lathes are really helpful. They let you change speeds quickly and easily. This means you can work on different materials without stopping much. It makes the work faster and more accurate. Plus, it helps keep everything running smoothly!”}},{“@type”: “Question”,”name”: “How Can Servo Motors Be Integrated Into A Metal Lathe’S Gear System To Enhance Precision And Automation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can add servo motors to a metal lathe’s gear system to make it work better. Servo motors help the lathe turn exactly how we want it to. This means our pieces will be made more accurately and neatly. With these motors, we can also set new tasks for the lathe to do automatically, helping us a lot!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting The Appropriate Gear Ratio For A Specific Metalworking Application In An Automated Lathe System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the right gear ratio for a lathe, think about the material you’re working with. Different metals need different speeds to cut well. Also, consider how much power you have. More power can help you cut faster. Lastly, think about the detail you want. For fine details, a slower speed might work better.”}},{“@type”: “Question”,”name”: “How Do Modern Control Systems For Metal Lathes Utilize Gear Ratios To Optimize Performance And Efficiency In Automated Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Modern control systems for metal lathes use gear ratios to help machines work better and faster. Gear ratios are like settings that control how quickly a tool turns. With the right gear ratio, the lathe can cut materials smoothly without wasting energy. This makes the lathe more efficient and helps us create better parts. So, by adjusting these ratios, we ensure machines do their best job.”}}]}