Do you know how important gear ratios are for metal lathes? Understanding lathe gear ratios can make a big difference in your projects. Imagine you’re working on a fun DIY project. Suddenly, you realize your lathe isn’t cutting right. Could the gear ratio be the issue?

Many people don’t think about this topic until they need to. It’s a lot more interesting than it sounds! Each brand of metal lathe has its unique design and features. Some brands even offer specialized gear ratios to enhance your work.

Here’s a fun fact: gear ratios determine how fast the lathe spins. A higher ratio means faster spinning, which can be great for big tasks. However, it may not be ideal for precise jobs. This is where knowing your options really helps!

So, which lathe gear ratio is right for you? Let’s explore the top metal lathe brands and what they offer. You might be surprised by the choices available! Get ready to dive into the exciting world of metal lathes, where each brand has something unique to offer.

Lathe Gear Ratio: Top Metal Lathe Brands Explained

Lathe Gear Ratio and Metal Lathe Brands

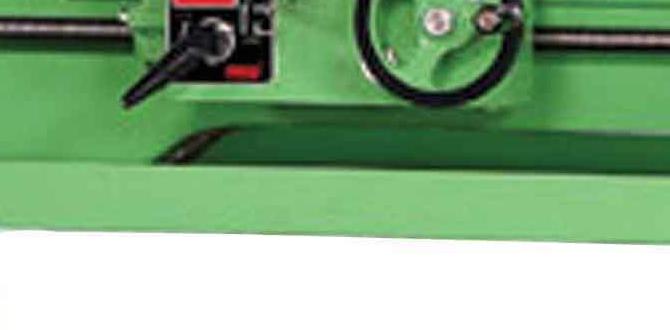

Understanding lathe gear ratios is essential when selecting the right metal lathe. The gear ratio affects the speed and torque of the lathe, influencing how projects turn out. Different brands offer various gear ratios, which can impact your work quality. Brands like Grizzly and Jet are popular for their reliability and performance. Choosing the right one can enhance your crafting experience. Curious about how gear ratios can change your projects? Exploring this may surprise you!What is Lathe Gear Ratio?

Definition and importance of gear ratio in lathes. How gear ratios affect machining precision and efficiency.The lathe gear ratio is a number that tells how fast the lathe spins the workpiece compared to the motor speed. It’s like a speedometer for your machine! A good gear ratio helps you make more precise cuts, which means your pieces fit together better. Imagine trying to cut a pizza with a dull knife – not fun, right?

Having the right gear ratio also means you use your machine’s power better, making your work quicker and easier. Here’s a fun fact: with the right setup, you can turn a big hunk of metal into a beautiful sculpture! That’s the magic of gears!

| Gear Ratio | Effect on Machining |

|---|---|

| High Ratio | More torque, slower speed – good for heavy cuts |

| Low Ratio | Faster speed, less torque – great for fine details |

How to Calculate Lathe Gear Ratio

Stepbystep calculation process for gear ratios. Examples of gear ratio calculations in metal lathes.Calculating a lathe’s gear ratio is simple and fun! Start by finding the number of teeth on the drive gear. Then, count the teeth on the driven gear. Divide the first number by the second. For example, if the drive gear has 20 teeth and the driven gear has 40, the ratio is 20 ÷ 40 = 0.5. This means one turn of the drive gear results in half a turn of the driven gear! See the table below for more examples:

| Drive Gear Teeth | Driven Gear Teeth | Gear Ratio |

|---|---|---|

| 10 | 30 | 0.33 |

| 15 | 60 | 0.25 |

| 25 | 50 | 0.5 |

Remember, if the numbers get too high, you might need a calculator or a friend with a super brain. Calculating gear ratios helps you choose the right settings for your metal lathe. Happy turning!

How Gear Ratio Influences Lathe Performance

Effects of gear ratios on speed, torque, and power usage. Realworld implications of gear ratios on machining operations.The gear ratio of a lathe plays a big role in how it works. It affects speed, torque, and power usage. When the gear ratio is high, the lathe spins slowly but has more torque. This is great for tough jobs. A low ratio means more speed but less torque, perfect for lighter tasks. The right gear ratio helps with precision and can save energy, making your work easier and faster.

Why is gear ratio important in machining?

The gear ratio is important because it helps match the machine’s speed and power to the job. For example, a lathe with a higher torque can cut through thick metal easily. In contrast, a faster lathe gives a smooth finish on softer materials.

Key Effects of Gear Ratios:

- High ratio = High torque, low speed.

- Low ratio = High speed, low torque.

- Better ratios save energy during machining.

Choosing the Right Gear Ratio for Your Needs

Factors to consider when selecting a gear ratio for specific projects. Recommendations for different types of machining tasks.Choosing the right gear ratio is key for successful machining. A few important factors to consider include the type of project, the material, and the desired finish. For example, a higher gear ratio is great for detailed work, while a lower ratio suits heavy cutting. Here are some recommendations:

- High precision tasks: Use a higher gear ratio.

- Heavy materials: Opt for a lower gear ratio.

- Fast production: Find a balance based on task needs.

- Finishing touches: Choose a medium gear ratio for smooth surfaces.

Selecting the right gear ratio helps achieve the best results for each project. This knowledge can make machining more effective.

What is the best gear ratio for different tasks?

The best gear ratio varies. For detail work, a higher ratio works best. For rough cuts, a lower ratio is ideal. Understanding your task helps you choose wisely.

Key Gear Ratio Recommendations

| Task Type | Recommended Gear Ratio |

|---|---|

| Detail Work | High Ratio |

| Rough Cuts | Low Ratio |

| Mixed Projects | Medium Ratio |

Maintenance Tips for Lathe Gear Systems

Best practices for maintaining gear systems in metal lathes. Common issues and troubleshooting tips related to gear ratios.Keeping gear systems in check ensures your metal lathe runs smoothly. Regular maintenance keeps everything working right. Check the oil levels often to maintain optimal function. Fix leaks right away to avoid bigger problems. Keep gears free of dirt and dust. Clean them regularly. Monitor any unusual sounds. These could signal trouble ahead. Remember, early fixes save time and effort.

What are common issues with lathe gear systems?

Common issues include strange noises, slipping gears, and uneven cuts. Listen for any weird sounds while working. These hints can help you spot problems before they get worse.

Tips to troubleshoot gear issues:

- Check gear alignment regularly.

- Examine for wear or damage.

- Inspect lubrication levels often.

Future Trends in Lathe Gear Technologies

Innovations in gear design and technology. Predictions for the evolution of gear ratios in the metalworking industry.Exciting times lie ahead for lathe gear technologies! Innovations in gear design mean better precision and efficiency. Experts predict that ratios will evolve, becoming more versatile. Picture gears that shift smoothly, like a cat landing from a jump! Even the metalworking world is ready for improvements that could double productivity.

| Innovation | Impact |

|---|---|

| Smart Gears | Increase precision |

| Adjustable Ratios | Boost flexibility |

These trends will shape how metalworkers create and design. Remember, change is coming. And it might just make us all a bit happier during long hours at the lathe!

Conclusion

In summary, understanding lathe gear ratios helps you choose the right metal lathe brand. Gear ratios affect speed and torque, which are important for your projects. Popular brands offer various options, so consider your needs. We suggest researching reviews and comparing features before purchasing. Explore more about lathe gear ratios to enhance your skills and make informed decisions!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios And Metal Lathe Brands:Sure! Let’s talk about lathe gear ratios. Gear ratios help us decide how fast a lathe turns. Different metal lathe brands may have different ratios. Some brands are better for small projects, while others are great for big ones. It’s important to pick the right lathe for what you want to make!

Sure! Please give me the question you want me to answer.

What Is The Significance Of Gear Ratio In The Performance And Precision Of A Metal Lathe?The gear ratio on a metal lathe is important because it helps control how fast the machine spins. A higher gear ratio means faster spinning, which is good for drilling holes. A lower gear ratio is better for cutting shapes because it gives more control. By choosing the right gear ratio, you can make your projects look cleaner and work better.

How Do Different Metal Lathe Brands Compare In Terms Of Gear Ratio Options For Various Machining Tasks?Different metal lathe brands offer various gear ratios. Gear ratios help you choose speeds for different tasks. Some brands have more options, which means you can work faster or slower. This helps when you need precision or speed. Always pick a brand that suits your needs best!

What Are Common Gear Ratio Configurations Found In High-Quality Metal Lathes From Leading Brands?In high-quality metal lathes, we often find gear ratios like 1:1, 1:2, and 1:4. This means for every turn of one gear, the other turns once, twice, or four times. These ratios help control the speed and power of the lathe. Some brands even offer more options for different projects. Choosing the right gear helps you work better and makes your work easier.

How Does The Gear Ratio Affect The Cutting Speed And Feed Rate On A Metal Lathe?The gear ratio is the relationship between how fast the lathe turns and how fast the tool moves. A higher gear ratio makes the lathe spin faster, which increases cutting speed. This helps cut metal quickly. However, if the feed rate—the speed at which the tool moves—is too fast, it can hurt the tool or workpiece. Finding the right balance is very important!

Which Metal Lathe Brands Are Known For Their Innovation In Gear Ratio Design And Functionality?Some metal lathe brands are really good at making special gear ratios. Brands like Haas and Grizzly are popular for new ideas. They help you change speeds easily. This makes it fun to use the lathe and do different projects. You can rely on these brands for their creative designs!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios And Metal Lathe Brands:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Let’s talk about lathe gear ratios. Gear ratios help us decide how fast a lathe turns. Different metal lathe brands may have different ratios. Some brands are better for small projects, while others are great for big ones. It’s important to pick the right lathe for what you want to make!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratio In The Performance And Precision Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio on a metal lathe is important because it helps control how fast the machine spins. A higher gear ratio means faster spinning, which is good for drilling holes. A lower gear ratio is better for cutting shapes because it gives more control. By choosing the right gear ratio, you can make your projects look cleaner and work better.”}},{“@type”: “Question”,”name”: “How Do Different Metal Lathe Brands Compare In Terms Of Gear Ratio Options For Various Machining Tasks?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different metal lathe brands offer various gear ratios. Gear ratios help you choose speeds for different tasks. Some brands have more options, which means you can work faster or slower. This helps when you need precision or speed. Always pick a brand that suits your needs best!”}},{“@type”: “Question”,”name”: “What Are Common Gear Ratio Configurations Found In High-Quality Metal Lathes From Leading Brands?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In high-quality metal lathes, we often find gear ratios like 1:1, 1:2, and 1:4. This means for every turn of one gear, the other turns once, twice, or four times. These ratios help control the speed and power of the lathe. Some brands even offer more options for different projects. Choosing the right gear helps you work better and makes your work easier.”}},{“@type”: “Question”,”name”: “How Does The Gear Ratio Affect The Cutting Speed And Feed Rate On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear ratio is the relationship between how fast the lathe turns and how fast the tool moves. A higher gear ratio makes the lathe spin faster, which increases cutting speed. This helps cut metal quickly. However, if the feed rate—the speed at which the tool moves—is too fast, it can hurt the tool or workpiece. Finding the right balance is very important!”}},{“@type”: “Question”,”name”: “Which Metal Lathe Brands Are Known For Their Innovation In Gear Ratio Design And Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some metal lathe brands are really good at making special gear ratios. Brands like Haas and Grizzly are popular for new ideas. They help you change speeds easily. This makes it fun to use the lathe and do different projects. You can rely on these brands for their creative designs!”}}]}