Have you ever wondered how a metal lathe can make such precise cuts? It all starts with the lathe gear ratio. This ratio plays a big role in how fast and smooth the lathe runs. But there’s more to it than just numbers.

Imagine you’re in a workshop, surrounded by machines that hum smoothly. You pick up a metal lathe chuck key, and suddenly, everything clicks into place. This simple tool helps tighten or loosen the chuck, which holds the material in place. Can you see how important that is?

Learning about lathe gear ratios and their impact on performance can feel like unlocking hidden secrets. Did you know that adjusting these ratios can completely change how the machine works? Understanding them opens up new possibilities in metalworking.

Join us in exploring the fascinating world of lathe gear ratios, the metal lathe chuck key, and how they work together to create precision in every project!

Understanding Lathe Gear Ratio And Metal Lathe Chuck Key

Understanding Lathe Gear Ratio, Metal Lathe, and Chuck Key

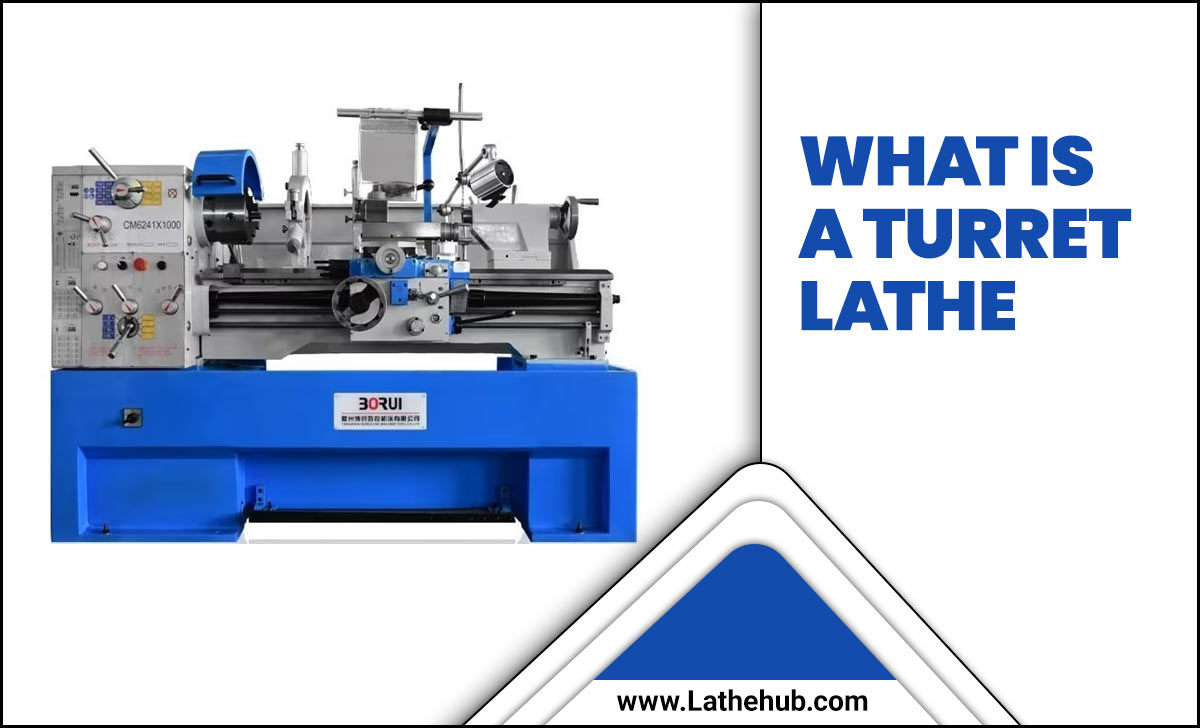

Lathe gear ratios help determine how fast your metal lathe works. A correct ratio balances speed and torque, making your projects more efficient. Did you know a well-maintained chuck key keeps your chuck tight? This ensures accurate cuts and safer operations. If your chuck slips, it can ruin your work. Choosing the right gear ratio and caring for your chuck key will boost your lathe’s performance and your crafting success.What is a Lathe Gear Ratio?

Definition and significance of gear ratios in lathe operations. How gear ratios affect cutting speed and torque.A lathe gear ratio is the relationship between the motor speed and the spindle speed. This ratio is crucial for lathe operations. It helps control how fast the cutting tool moves. A higher gear ratio means faster cutting speeds but less torque. This can be great for soft materials. A lower gear ratio gives more torque, which is useful for harder materials. Adjusting the gear ratio affects performance. It’s important to choose the right one for your project.

How does gear ratio affect lathe performance?

The gear ratio alters both speed and power in a lathe.

- Speed: Faster speeds can cut through materials quickly.

- Torque: Higher torque is needed for tougher materials.

Calculating Lathe Gear Ratios

Stepbystep process for calculating gear ratios. Common formulas and examples for practical understanding.Calculating gear ratios can feel like math class, minus the sweat! First, you take the number of teeth on the motor gear. Then, you divide it by the number of teeth on the driven gear. Voila! You’ve got your ratio. For an easy formula, just use: Gear Ratio = Teeth on Motor / Teeth on Driven. For example, if the motor gear has 20 teeth and the driven gear has 40, the ratio is 0.5. Time to get those gears spinning!

| Motor Gear Teeth | Driven Gear Teeth | Gear Ratio |

|---|---|---|

| 20 | 40 | 0.5 |

| 10 | 30 | 0.33 |

| 15 | 45 | 0.33 |

Each gear ratio helps in understanding how fast the lathe spins. Remember, a higher ratio means more torque, but less speed. So, keep this in mind when using a metal lathe chuck key!

The Role of Chuck Keys in Metal Lathes

Purpose of chuck keys in securing workpieces. Different types of chuck keys and their specific uses.Chuck keys are like best friends for metal lathes. They hold the workpiece securely in place so it doesn’t dance around while you’re working. Without a good chuck key, your workpiece might escape, causing a messy shop and a very surprised worker!

There are various types of chuck keys designed for different needs. Some are T-shaped for extra grip, while others are keyless for quick changes. Each type has its own special job, kind of like superheroes with unique powers! Check the table below to see which chuck key works best for you:

| Chuck Key Type | Usage |

|---|---|

| T-Shaped | Offers strong grip for larger pieces |

| Keyless | Quick changes made easy |

| Spring-Loaded | Adjusts pressure automatically |

So, remember to choose the right chuck key. It will save you from unexpected surprises and keep your projects rolling smoothly!

Selecting the Right Chuck Key for Your Lathe

Factors to consider when choosing a chuck key. Compatibility with various lathe models.Choosing the right chuck key for your lathe is important. Here are some key factors to think about:

- Size: The chuck key needs to fit tightly into your lathe’s chuck.

- Type: Consider whether you need a standard or a quick-release chuck key.

- Build Quality: Look for sturdy materials that will last.

- Compatibility: Ensure the chuck key works with your lathe model.

Using the right chuck key makes your work easier and safer. Always check your lathe manual for more details on required sizes and styles.

What should I consider when choosing a chuck key?

Size, type, and compatibility are key points. Make sure it fits your lathe well for safety and better function.

Maintaining Your Gear Ratio and Chuck Key

Best practices for maintaining lathe gear systems. Tips for keeping chuck keys in optimal condition.Keeping your gear system and chuck key in good shape is important for your lathe. Follow these best practices:

- Check your gear ratio regularly. This helps maintain smooth operation.

- Clean the gear system. Dust can cause problems.

- Lubricate the gears as needed to avoid wear.

- Store your chuck key in a safe place. This prevents loss.

- Inspect the chuck key for damage often. Replace if needed.

Taking care of these parts keeps your lathe working well and lasts longer.

How can I maintain my lathe gear system?

Regular checks, cleaning, and lubrication are key to maintenance.

What is the best way to keep a chuck key in good condition?

Keep it stored safely and check for damage often.

Common Issues with Gear Ratios and Chuck Keys

Troubleshooting common problems related to gear ratios. Identifying and resolving issues with chuck keys.When using a metal lathe, several problems can arise with gear ratios and chuck keys. Here are some common issues and their fixes:

- Gear Ratio Issues: If the lathe isn’t cutting correctly, check the gear ratio. A wrong ratio can lead to mistakes in speed and power. Always refer to the manual to find the right settings.

- Chuck Key Problems: Misplaced or damaged chuck keys can stop your work. Always keep your chuck key handy, and replace it if it looks worn out. A rubber grip can help hold it better.

What should I do if my lathe is cutting unevenly?

If your lathe cuts unevenly, check the gear settings first. Make sure they match what your project needs. If needed, adjust the gear ratio for a smoother cut.

Why is my chuck key hard to turn?

A hard-to-turn chuck key might indicate dirt or debris inside. Clean the area with a brush. If it still feels stiff, consider replacing the chuck key.

Real-Life Applications of Lathe Gear Ratios and Chuck Keys

Case studies of production environments utilizing optimized gear ratios. Examples of effective chuck key usage in various metalworking projects.In various production environments, optimized gear ratios make a big difference. For example, factories often adjust gear ratios to boost speed and precision. This can lead to smoother operations and less machine wear—like a happy dance for your lathe! Meanwhile, chuck keys aren’t just handy; they’re vital for keeping tools tight. Whether you’re crafting delicate parts or heavy components, using a chuck key correctly helps avoid mishaps. Their proper use can save time and improve safety. It’s like having a superhero tool in your toolbox!

| Application | Benefit |

|---|---|

| Optimized Gear Ratios | Increases speed and precision |

| Proper Chuck Key Use | Ensures safety and saves time |

Conclusion

In summary, understanding the lathe gear ratio and how it affects your metal lathe chuck key is important. It helps you adjust speed and accuracy for better results. By learning these concepts, you can improve your machining skills. Experiment with your gear ratios and read more about lathe techniques to enhance your projects. Dive in and start making!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios, Metal Lathe Operations, And Chuck Keys:Sure! Here are five questions about lathe gear ratios, metal lathe operations, and chuck keys: 1. What is a lathe? A lathe is a machine that helps shape metal or wood. It spins the material so we can cut it into different shapes. 2. What is a gear ratio? A gear ratio tells us how fast the lathe turns the objects. It shows how the big and small gears work together. 3. Why do we use a chuck key? We use a chuck key to tighten or loosen the chuck. The chuck holds the piece of metal or wood in place. 4. How do we use a lathe? To use a lathe, we first secure our material with the chuck. Then, we turn it on and shape it with tools. 5. What safety steps should we take with a lathe? We should wear safety goggles, keep our hands away from moving parts, and follow the rules carefully.

Sure! Please give me the question you would like me to answer, and I’ll be happy to help.

What Is The Significance Of Gear Ratios In A Metal Lathe, And How Do They Affect Cutting Speeds?Gear ratios in a metal lathe help control how fast the machine spins and cuts. When you change the gear ratio, you change the cutting speed. A higher gear ratio makes the cutting tool spin faster, which is great for softer materials. A lower gear ratio slows it down, allowing for better control on hard materials. This way, we can make better and smoother pieces.

How Do You Determine The Appropriate Lathe Gear Ratio For Specific Materials And Cutting Operations?To find the right lathe gear ratio, start by thinking about the material you’re working with. Softer materials need a faster speed, so you use a higher gear ratio. Harder materials need slower speeds, so you choose a lower gear ratio. You can also check the lathe manual for tips on gear settings for different materials. Remember, it’s all about matching the speed to the material!

What Are The Different Types Of Chuck Keys Used With Metal Lathe Chucks, And How Do They Vary In Their Design And Functionality?There are a few types of chuck keys for metal lathe chucks. The most common ones are T-handle and pin-type keys. T-handle keys look like a T and help us grip tightly. Pin-type keys have small pins that fit into holes. Each type works the same way, but they fit different chuck designs.

How Can Improper Use Of A Chuck Key Affect The Performance And Safety Of A Metal Lathe?Using a chuck key the wrong way can cause the chuck to be loose. This means the piece you’re working on might spin out of control. If that happens, it could hurt you or damage the lathe. Always use the chuck key correctly to stay safe and work well.

What Steps Should Be Taken To Properly Maintain And Adjust The Gear Ratio Settings On A Metal Lathe For Optimal Performance?To keep your metal lathe working well, follow these steps. First, always check the user manual for gear ratio settings. Then, clean the lathe to remove dirt and grease. After that, adjust the gears according to the instructions for the task you are doing. Finally, test the lathe with a small piece of metal to make sure it runs smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios, Metal Lathe Operations, And Chuck Keys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe gear ratios, metal lathe operations, and chuck keys: 1. What is a lathe? A lathe is a machine that helps shape metal or wood. It spins the material so we can cut it into different shapes. 2. What is a gear ratio? A gear ratio tells us how fast the lathe turns the objects. It shows how the big and small gears work together. 3. Why do we use a chuck key? We use a chuck key to tighten or loosen the chuck. The chuck holds the piece of metal or wood in place. 4. How do we use a lathe? To use a lathe, we first secure our material with the chuck. Then, we turn it on and shape it with tools. 5. What safety steps should we take with a lathe? We should wear safety goggles, keep our hands away from moving parts, and follow the rules carefully.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you would like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratios In A Metal Lathe, And How Do They Affect Cutting Speeds?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios in a metal lathe help control how fast the machine spins and cuts. When you change the gear ratio, you change the cutting speed. A higher gear ratio makes the cutting tool spin faster, which is great for softer materials. A lower gear ratio slows it down, allowing for better control on hard materials. This way, we can make better and smoother pieces.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Lathe Gear Ratio For Specific Materials And Cutting Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right lathe gear ratio, start by thinking about the material you’re working with. Softer materials need a faster speed, so you use a higher gear ratio. Harder materials need slower speeds, so you choose a lower gear ratio. You can also check the lathe manual for tips on gear settings for different materials. Remember, it’s all about matching the speed to the material!”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Chuck Keys Used With Metal Lathe Chucks, And How Do They Vary In Their Design And Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few types of chuck keys for metal lathe chucks. The most common ones are T-handle and pin-type keys. T-handle keys look like a T and help us grip tightly. Pin-type keys have small pins that fit into holes. Each type works the same way, but they fit different chuck designs.”}},{“@type”: “Question”,”name”: “How Can Improper Use Of A Chuck Key Affect The Performance And Safety Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a chuck key the wrong way can cause the chuck to be loose. This means the piece you’re working on might spin out of control. If that happens, it could hurt you or damage the lathe. Always use the chuck key correctly to stay safe and work well.”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Properly Maintain And Adjust The Gear Ratio Settings On A Metal Lathe For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe working well, follow these steps. First, always check the user manual for gear ratio settings. Then, clean the lathe to remove dirt and grease. After that, adjust the gears according to the instructions for the task you are doing. Finally, test the lathe with a small piece of metal to make sure it runs smoothly.”}}]}