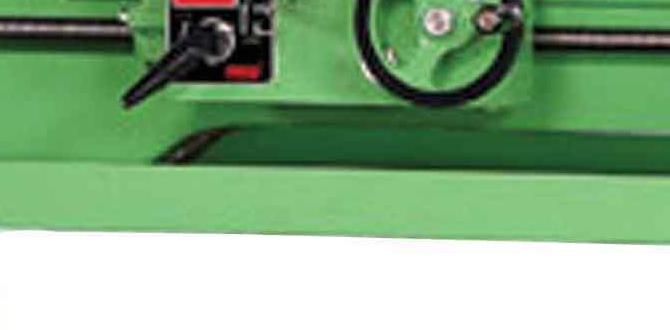

If you’ve ever wondered how metal lathes work, you’re not alone. Many hobbyists and professionals are curious about these amazing machines. One important part of a lathe is the gear ratio. It controls how fast the lathe turns the workpiece. But why does this matter?

Imagine you’re trying to carve a beautiful design into a piece of metal. If your lathe spins too fast, you may ruin your work. If it spins too slowly, you’ll take forever to finish. The right gear ratio makes all the difference.

Have you heard about the compound rest on a lathe? This part helps you move the cutting tool exactly where you want it. When used with the right gear ratio, it can create perfect grooves and shapes. Isn’t it fascinating how these simple elements work together to create something great?

Dive in with us as we explore the world of lathe gear ratios, the metal lathe, and the compound rest. You might just discover a new favorite hobby or skill!

Understanding Lathe Gear Ratio For Metal Lathe Compound Rest

Lathe Gear Ratio: Understanding the Metal Lathe Compound Rest

Lathe gear ratios are vital for achieving precision in metalworking. The compound rest allows you to adjust the angle of cuts easily. Have you ever wondered how a small change can affect the final product? By modifying the gear ratio, you can control the spindle speed and torque. This impacts everything from threading to shaping. A well-set gear ratio ensures smooth operation and enhances the quality of your projects. Isn’t it fascinating how mechanics and creativity blend in metal lathes?Understanding Lathe Gear Ratios

Definition and significance of gear ratios in metal lathes. How gear ratios affect cutting speed and torque.Lathe gear ratios are essential for metal lathes. They define how the machine translates motor speed into cutting speed. A higher gear ratio means faster cutting, while a lower ratio offers more torque for tough materials. This balance is important for precision and performance.

- Gear ratio affects cutting speed

- Higher ratios increase speed

- Lower ratios boost torque

Understanding gear ratios helps users choose the right settings. This knowledge can lead to better results in metalworking projects.

What is the importance of gear ratios in metal lathes?

Gear ratios are important because they help control the cutting speed and torque of a lathe. Knowing how to adjust them allows for better machining of different materials.

Calculating Gear Ratios for Your Lathe

Stepbystep guide to calculating gear ratios. Common formulas used in determining gear ratios.Want to measure gear ratios for your lathe? It’s pretty simple! Start with the formula: Gear Ratio = Drive Gear Teeth ÷ Driven Gear Teeth. First, count the teeth on both gears. Then divide the drive gear’s teeth by the driven gear’s. Voila! You have your ratio. If you’re feeling adventurous, here’s a quick table:

| Drive Gear Teeth | Driven Gear Teeth | Gear Ratio |

|---|---|---|

| 12 | 4 | 3:1 |

| 20 | 10 | 2:1 |

The lower the ratio, the faster the lathe spins. Remember, a high ratio means more torque but less speed—kind of like a tortoise in a race! So, choose wisely to make your metal magic happen!

Choosing the Right Gear Ratio

Factors influencing the selection of gear ratios. How to improve machining efficiency with optimal gear ratios.Choosing the best gear ratio can make a big difference in how well your metal lathe works. Several factors influence your choice. These include the type of material you’ll use, the size of the project, and the speed you need.

Using the right gear ratio can improve machining efficiency significantly. It helps your machine cut faster and smoother. Here are some tips:

- Understand the material properties.

- Consider part sizes and weight.

- Match speed to task type.

By selecting optimal gear ratios, you can enhance your lathe’s performance and save time. Remember, wise gear choices lead to better results!

How does gear ratio affect lathe performance?

Gear ratio affects the speed and torque of the lathe, which influences cutting ability and finish quality. Choosing the right ratio improves accuracy and reduces errors.

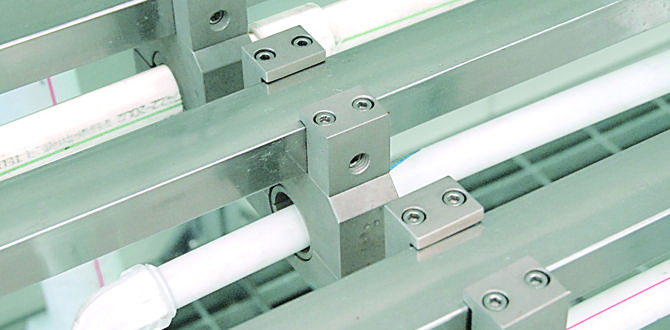

Adjusting the Compound Rest

Instructions on adjusting the compound rest for various operations. Importance of precision in setting the compound rest.Setting the compound rest correctly is key for smooth operations on your metal lathe. Start by loosening the lock nuts. Adjust the rest to the desired angle, ensuring a snug fit to avoid unexpected wobbles. Remember, a small slip can lead to big mistakes. In fact, just a tiny misalignment could turn your metal masterpiece into a lopsided creation! It’s all about precision—as they say, “Measure twice, cut once!”

| Operation Type | Angle Setting |

|---|---|

| Taper Turning | Set to desired taper angle |

| Face Turning | 0 degrees (flat position) |

| Thread Cutting | Refer to thread pitch |

The right setup can save you time and materials. Embrace the art of adjustment!

Common Issues with Gear Ratios and Compound Rest

Troubleshooting gear ratiorelated problems. Solutions for common compound rest malfunctions.Problems with gear ratios and the compound rest can be tricky. If your lathe isn’t working right, check the gear ratios first. A mismatch can mess up your cuts. For the compound rest, it might get stuck or move unevenly. Don’t throw a tantrum! A little oil can often fix it. If it’s still acting cranky, adjust the screws carefully, and voilà! You’re back in business.

| Issue | Solution |

|---|---|

| Poor gear ratio | Check alignment and replace damaged gears. |

| Stuck compound rest | Apply lubricating oil and check for debris. |

| Uneven movement | Adjust screws for better alignment. |

Best Practices for Maintenance

Tips for maintaining gear systems in metal lathes. Routine checks for the compound rest and associated components.Keeping your metal lathe in tip-top shape doesn’t have to be a chore. Regular care is key! Check the gear systems often. Look for wear and tear—like a shy puppy, they’ll show signs if they’re not happy! Keep the compound rest clean and lubricated for smooth movement. A good rule? If it squeaks, it’s time for a checkup!

| Maintenance Task | Frequency |

|---|---|

| Inspect gears | Weekly |

| Clean the compound rest | Daily |

| Lubrication | Monthly |

Remember, a well-maintained lathe is like a well-fed pet; it performs better and lasts longer. So, show some love, and your lathe will always be ready to roll!

Advancements in Lathe Technology

Recent innovations in gear ratio and compound rest design. Future trends in metal lathe technology and their impact on gear ratios.Recent years have brought exciting changes in lathe technology. New innovations in gear ratios enable more precise cuts, almost like magic! The compound rest design has improved too, making adjustments easier and smoother. In the future, metal lathes may adopt smart tech to predict maintenance needs, reducing downtime. Imagine a lathe that reminds you it’s time for a little TLC! Experts predict these advancements will boost fun and creativity in metalworking.

| Feature | Old Design | New Innovation |

|---|---|---|

| Gear Ratio | Standard | Variable with smart adjustments |

| Compound Rest | Manual adjustments | Easy-click mechanisms |

Practical Applications of Gear Ratios

Realworld examples of gear ratio use in metalworking. Case studies highlighting effective gear ratio adjustments.Gear ratios play a big role in metalworking. They help machines run better and adapt to different tasks. For example, modifying gear ratios can increase speed or torque. A factory measured performance before and after adjusting the gear ratio on a lathe. They found it improved cutting speed by 30%! Here are some examples:

- Using higher ratios for finer cuts.

- Lower ratios for more power in heavy materials.

- Adjusting ratios to reduce tool wear.

These adjustments lead to smoother operations and better results.

Why are gear ratios important in metalworking?

Gear ratios help machines work more efficiently. They allow for different speeds and strengths, which is crucial in tasks like shaping metal.

Conclusion

In summary, understanding lathe gear ratios helps you control speed and torque on a metal lathe. The compound rest allows for precise cutting angles. By mastering these concepts, you can improve your metalworking skills. We encourage you to explore more about gear ratios and practice using the compound rest. You’ll create better projects with hands-on experience!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio, Metal Lathe, And Compound Rest:Sure! A lathe is a tool that spins metal to shape it. The gear ratio helps you control how fast this happens. If you change the gears, you can make different cuts. The compound rest is a part that helps you angle the tool for better shapes. It makes your work easier and more precise!

Sure! Please provide the question you’d like me to answer.

What Is The Significance Of Gear Ratios In The Operation Of A Metal Lathe, And How Do They Affect Cutting Speed And Torque?Gear ratios in a metal lathe are important because they help control how fast the machine spins. When we change the gear ratio, we can make the lathe turn faster or slower. If the lathe spins faster, it cuts quickly but might be less strong. If it spins slower, it cuts better but with more power. So, gear ratios help us find the right balance between speed and strength when cutting metal.

How Can The Compound Rest Be Utilized To Enhance Precision And Control When Machining At Different Angles On A Metal Lathe?You can use the compound rest on a metal lathe to help you cut at different angles. It lets you adjust the cutting tool easily. By tilting the rest, you can create precise shapes and sizes. This means your work will fit better and look nicer. Using the compound rest makes your projects more accurate and controlled!

What Are The Common Gear Ratios Used In Metal Lathes For Different Machining Operations, And How Do They Influence The Resulting Finishes?In metal lathes, we often use gear ratios like 1:1, 1:2, or 1:4. A 1:1 ratio spins the tool at the same speed as the lathe. This gives a nice finish for fine details. A 1:2 ratio spins the tool faster, making rough cuts quicker but less smooth. Lower ratios like 1:4 can help with super smooth finishes but might take longer.

How Do You Calculate The Appropriate Gear Ratio For A Specific Machining Task On A Metal Lathe?To calculate the right gear ratio for a metal lathe, you first need to know your job. Think about how fast you want the metal to spin and how much you want to cut. Then, look at the gears on your lathe. You divide the number of teeth on the driving gear by the number of teeth on the driven gear. This gives you the gear ratio, which helps you pick the best setting for your task.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of The Gear System And Compound Rest In A Metal Lathe?To keep the gear system and compound rest in your metal lathe working well, you should do a few things. First, always clean the parts to remove dirt and dust. Second, you should check for any loose screws and tighten them if needed. Third, apply oil to moving parts to make them work smoothly. Lastly, store your lathe in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio, Metal Lathe, And Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that spins metal to shape it. The gear ratio helps you control how fast this happens. If you change the gears, you can make different cuts. The compound rest is a part that helps you angle the tool for better shapes. It makes your work easier and more precise!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratios In The Operation Of A Metal Lathe, And How Do They Affect Cutting Speed And Torque?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios in a metal lathe are important because they help control how fast the machine spins. When we change the gear ratio, we can make the lathe turn faster or slower. If the lathe spins faster, it cuts quickly but might be less strong. If it spins slower, it cuts better but with more power. So, gear ratios help us find the right balance between speed and strength when cutting metal.”}},{“@type”: “Question”,”name”: “How Can The Compound Rest Be Utilized To Enhance Precision And Control When Machining At Different Angles On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use the compound rest on a metal lathe to help you cut at different angles. It lets you adjust the cutting tool easily. By tilting the rest, you can create precise shapes and sizes. This means your work will fit better and look nicer. Using the compound rest makes your projects more accurate and controlled!”}},{“@type”: “Question”,”name”: “What Are The Common Gear Ratios Used In Metal Lathes For Different Machining Operations, And How Do They Influence The Resulting Finishes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes, we often use gear ratios like 1:1, 1:2, or 1:4. A 1:1 ratio spins the tool at the same speed as the lathe. This gives a nice finish for fine details. A 1:2 ratio spins the tool faster, making rough cuts quicker but less smooth. Lower ratios like 1:4 can help with super smooth finishes but might take longer.”}},{“@type”: “Question”,”name”: “How Do You Calculate The Appropriate Gear Ratio For A Specific Machining Task On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calculate the right gear ratio for a metal lathe, you first need to know your job. Think about how fast you want the metal to spin and how much you want to cut. Then, look at the gears on your lathe. You divide the number of teeth on the driving gear by the number of teeth on the driven gear. This gives you the gear ratio, which helps you pick the best setting for your task.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of The Gear System And Compound Rest In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the gear system and compound rest in your metal lathe working well, you should do a few things. First, always clean the parts to remove dirt and dust. Second, you should check for any loose screws and tighten them if needed. Third, apply oil to moving parts to make them work smoothly. Lastly, store your lathe in a dry place to prevent rust.”}}]}