Have you ever wondered how a metal lathe makes precise parts? A secret lies in the lathe gear ratio. This simple but powerful setting controls the speed and power of the lathe. It lets the machine spin at the perfect rate for different tasks.

Picture this: you have a block of metal, and you want to shape it into a sleek design. How do you get it just right? That’s where the lathe gear ratio comes into play. A well-set ratio makes all the difference.

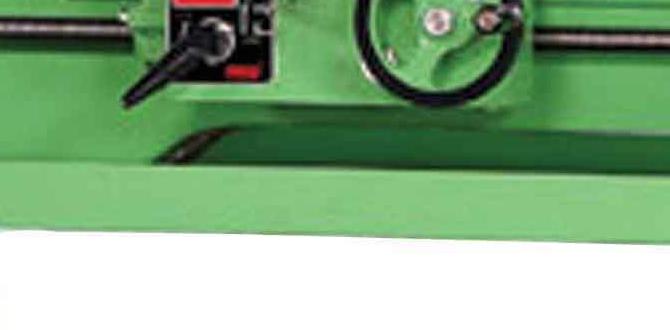

The control panel of a metal lathe is like a pilot’s cockpit. It allows you to adjust the gear ratio based on your needs. With just a few tweaks, you can switch from cutting to shaping. Amazing, right?

In this article, we’ll explore the lathe gear ratio and its importance. We’ll also dive into how the control panel makes it all happen. By the end, you’ll see why understanding this topic is important for anyone who loves working with metal.

Understanding Lathe Gear Ratio In Metal Lathe Control Panel

Understanding Lathe Gear Ratio in Metal Lathe Control Panels

Choosing the right lathe gear ratio is crucial for precision in metalworking. The gear ratio helps control the speed and torque of the machine. This means you can work on different materials effectively. For instance, a higher ratio offers more torque but less speed. Have you ever wondered how a simple twist can achieve such power? A well-set control panel can enhance your crafting experience, making complex tasks easier and more fun!What is a Lathe Gear Ratio?

Definition and importance in metalworking.. How gear ratios affect cutting speed and torque..A lathe gear ratio tells us how the lathe’s motor speed connects to the speed of the cutting tool. This is important in metalworking because it affects how fast and how strong the machine cuts. A good gear ratio helps create smooth, precise shapes. With the right ratio, cutting speed increases and torque, or turning power, improves.

Why does gear ratio matter?

Gear ratios help control cutting speed and torque. A higher ratio gives faster cutting but lower torque, while a lower ratio offers more torque and slower cutting. It’s all about finding balance!

- High gear ratio = fast cutting speed

- Low gear ratio = more torque

How to Calculate Lathe Gear Ratios

Stepbystep method to determine gear ratios.. Common formulas used in calculations..To find the lathe gear ratio, follow these simple steps. First, count the teeth on the driving gear. Next, count the teeth on the driven gear. Now, use the formula:

- Gear Ratio = Number of Teeth on Driven Gear ÷ Number of Teeth on Driving Gear

This method helps you see how the gears work together. Remember, a higher ratio means faster speed. Your metal lathe control panel can also show these numbers. Check it for quick calculations!

What is a common formula for gear ratios?

The main formula is Gear Ratio = Teeth on Driven Gear ÷ Teeth on Driving Gear. This helps you make precise cuts.

Common Gear Ratios Used in Metal Lathes

Typical gear ratios for various applications.. Advantages of using specific gear ratios..Metal lathes often use common gear ratios like 2:1, 4:1, and 6:1. Each ratio works best for different tasks. Higher ratios allow for finer cuts, while lower ratios offer faster speeds. Here are some benefits of using specific gear ratios:

- Increased precision: Fine adjustments lead to better results.

- Improved speed: Faster setups can save time on tasks.

- Extended tool life: Proper ratios reduce wear on tools.

Adjusting Gear Ratios for Optimal Performance

Best practices for tuning gear settings.. Impact of adjustments on workpiece quality..Tuning gear settings can greatly improve your metal lathe’s performance. Here are some best practices for adjusting gear ratios:

- Always check the manufacturer’s guide.

- Make small changes to see their effects.

- Test the lathe with scrap materials first.

Proper adjustments can lead to better workpiece quality. You may notice:

- Smoother surfaces on the finished piece.

- Less wasted material.

- Faster production times.

Maintaining gear ratios ensures your lathe works well and produces high-quality parts.

How does adjusting the gear ratio affect my lathe?

Adjusting the gear ratio can improve speed and precision. It helps your lathe match the project’s needs better.

Troubleshooting Gear Ratio Issues

Common problems associated with incorrect gear ratios.. Diagnostic tips for control panel malfunctions..Gear ratio problems can cause your metal lathe to act up. Here are some common issues you might see:

- The motor runs but the spindle doesn’t turn.

- You hear strange noises during operation.

- The lathe doesn’t cut properly or skips teeth.

To fix control panel malfunctions, try these tips:

- Check connections and cables for any damage.

- Reset the machine and see if that helps.

- Look for error messages on the screen.

These steps can help you find and fix gear ratio issues. Remember, regular checks can save time and trouble!

What are common signs of gear ratio issues?

Common signs include strange noises, lack of movement, and poor cutting performance. These issues often link back to incorrect gear ratios.

Upgrading Control Panel Features

Modern technology enhancements in control panels.. Benefits of using digital vs. analog controls..Control panels for metal lathes have come a long way, making things much smoother than a buttered slide! Modern panels offer shiny digital displays instead of old-school dials. These digital controls are like having a calculator instead of an abacus. They provide clear readings and precise adjustments. It’s much easier to read numbers than to squint at needles!

| Feature | Digital Control | Analog Control |

|---|---|---|

| Precision | High | Moderate |

| Readability | Easy | Hard |

| Setup Time | Quick | Slow |

This upgrade means fewer mistakes and faster setups. Isn’t that a win-win? Plus, digital panels often have cool features like speed settings that can be adjusted with a button. Who knew upgrading a control panel could be this exciting? It’s like swapping a horse for a race car!

Maintenance Tips for Gear Systems and Control Panels

Routine maintenance practices for longevity.. Signs that maintenance or repair is needed..Keeping your gear systems and control panels happy is like giving a pet a good scratch. Routine checks are key! Make sure to clean and lubricate parts every few weeks. This keeps everything running smoothly and increases the life of your metal lathe. But how do you know if something’s wrong? Look for strange noises or jerky movements. These could be signs that a fix is needed!

| Signs You Need Maintenance | What to Do |

|---|---|

| Unusual Sounds | Check for loose parts. |

| Sluggish Response | Lubricate moving parts. |

| Visible Wear | Replace damaged components. |

Remember, a little tlc goes a long way! Think of it as giving your lathe a spa day. It deserves it!

Conclusion

In conclusion, understanding lathe gear ratios helps you control your metal lathe effectively. A gear ratio affects speed and torque. Familiarize yourself with your control panel to maximize your lathe’s performance. Remember, practice makes perfect! Explore more resources or manuals about lathe settings for deeper knowledge. You’ll improve your skills with time and hands-on experience. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Gear Ratios And Metal Lathe Control Panels:Sure! When we talk about lathe gear ratios, we mean how fast the lathe spins compared to the motor. A higher gear ratio makes the lathe spin slower but with more power. In a metal lathe control panel, there are buttons and knobs that let you change the speeds and settings. This helps you create the shapes you want in metal. It’s like adjusting your bike gears to ride faster or slower!

Sure! Please tell me the question you would like answered.

What Is The Significance Of Gear Ratios In A Metal Lathe, And How Do They Affect Machining Precision And Speed?Gear ratios in a metal lathe help control how fast the machine turns. When we change the gear ratio, we can make it spin quickly or slowly. A slower speed means more precision, so we can make detailed cuts. A faster speed helps us work quickly, but we must be careful not to mess up. So, gear ratios help us find the right balance between speed and accuracy!

How Do You Adjust The Gear Ratio On A Metal Lathe Control Panel For Different Types Of Cutting Tasks?To adjust the gear ratio on a metal lathe, you first look at the control panel. You will see different settings. To change the gear ratio, you turn a knob or flip a switch. Higher ratios are for faster cutting, while lower ones slow it down. Choose the right setting for the type of cutting you want to do!

What Common Issues Can Arise From Incorrect Gear Ratio Settings On A Lathe, And How Can They Be Resolved?If you set the wrong gear ratio on a lathe, your work can become uneven. This can cause extra strain on the machine. You might also get a rough finish on the item you are making. To fix this, you should check the settings carefully and adjust them to the right numbers. Make sure you follow the instructions for your lathe!

How Do Digital Control Panels Differ From Traditional Mechanical Setups In Terms Of Managing Gear Ratios On Metal Lathes?Digital control panels let you change gear ratios easily with buttons or a touch screen. With traditional mechanical setups, you have to move parts by hand, which can take more time. Digital systems can also show you which gear ratio you are using in real-time. This makes it simpler for you to control the machine. Overall, digital panels are faster and easier to use.

What Are Some Best Practices For Maintaining The Gear System In A Metal Lathe To Ensure Optimal Performance And Longevity?To keep the gear system in a metal lathe working well, you should clean it regularly. Dust and chips can mess things up. You also need to check for worn-out parts and replace them when needed. Remember to oil the gears to keep them running smoothly. Lastly, always follow the manufacturer’s instructions for care.