Have you ever wondered how a small machine can create such amazing parts? A metal lathe is one of those machines. It shapes metal into different forms. To get the best results, you need to understand its gear ratio. But what does that mean?

Lathe gear ratios play a key role in how your metal lathe works. The right ratio helps you control speed and torque. This means you can make precise cuts on metal pieces. But how do you choose the right metal lathe for your projects?

In this article, we will dive into lathe gear ratio metal lathe reviews. We will explore different options and help you find the best fit for your needs. With so many choices, it can feel confusing. But don’t worry! By the end, you’ll be ready to pick the right lathe and tackle your next project.

Did you know that many makers and hobbyists prefer using lathes? They enjoy making custom pieces, from parts for machines to beautiful art. As you read on, you’ll discover why gear ratios are essential to their success.

Lathe Gear Ratio: Metal Lathe Reviews And Insights

Lathe Gear Ratio Metal Lathe Reviews

When considering a metal lathe, gear ratio plays a big role in performance. Different lathes offer various gear ratios that impact speed and torque. Reviews highlight how lathes with higher gear ratios enable faster work, but may lack power for heavy-duty tasks. Many users appreciate lathes that balance speed and strength. Did you know that even small adjustments in gear ratios can change your project results? Choosing the right lathe is key to achieving your best work.Understanding Lathe Gear Ratios

Definition and significance of gear ratios in metal lathes. How gear ratios affect performance and precision.Gear ratios are key in metal lathes. They show how the speed of the motor and the tool relate. A lower gear ratio means more torque, which is great for heavy cuts. A higher gear ratio allows for faster spins, which is better for lighter work. Understanding this helps in making the right choice for projects. You want a good balance of speed and power to get the best results.

What do gear ratios affect in a lathe?

Gear ratios influence performance and precision. The right ratio gives better finishes and smoother cuts. This means jobs are done faster and with higher quality.

- Low Gear Ratio: More power, less speed

- High Gear Ratio: More speed, less power

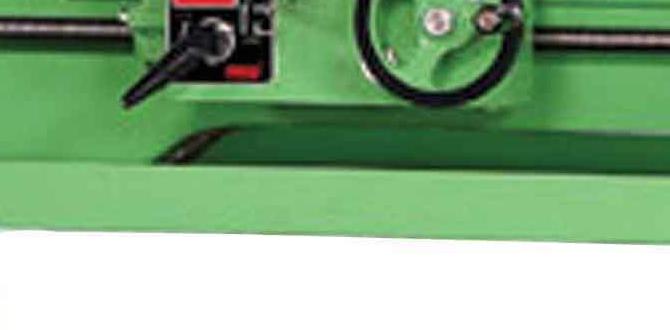

Key Features to Consider in Metal Lathes

Important specifications: horsepower, swing, and bed length. Control options: manual vs. CNC lathes.Metal lathes come with important features that make them stand out. You should think about the following:

- Horsepower: More power means better cutting strength.

- Swing: This tells you how large the workpiece can be.

- Bed Length: A longer bed allows bigger jobs.

Control options matter, too. You can choose between:

- Manual lathes: These give you direct control. Good for learning.

- CNC lathes: These use computers to control settings, making them precise.

Think about these features. They help you pick the right metal lathe for your projects!

What specifications should I look for in a metal lathe?

Look for horsepower, swing, and bed length to match your needs.

How to Choose the Right Gear Ratio for Your Projects

Factors influencing gear ratio selection: material type, workpiece size. Recommendations based on common metalworking tasks.Choosing the right gear ratio is important for your projects. Several factors can influence your decision. First, consider the material type of your workpieces. Softer materials may need lower gear ratios for better control, while harder materials may require higher ratios. Also, think about the workpiece size. Larger pieces often need a different approach than smaller ones. Here are some quick tips:

- Soft materials: Lower gear ratios work best.

- Hard materials: Opt for higher gear ratios.

- Small pieces: Use finer settings for precision.

- Large pieces: Choose settings that provide more power.

By recognizing these factors, you ensure better results in your metalworking tasks. Choose wisely for a great finish!

What factors should I consider for gear ratio?

Consider material type and workpiece size when selecting gear ratios.What are common recommendations based on tasks?

For soft materials, use lower gear ratios. For larger, harder materials, opt for higher ratios.Maintenance Tips for Gear Mechanisms

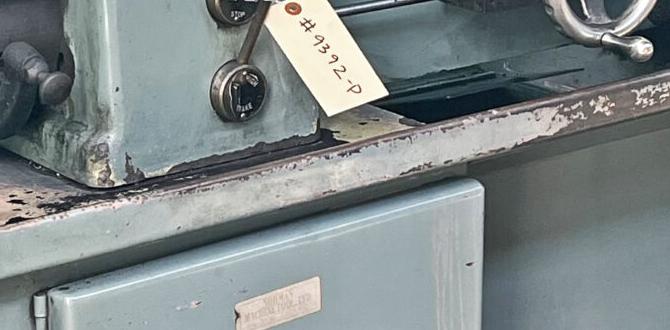

Steps to maintain gear systems in metal lathes. Signs of wear and when to seek professional help.Keeping your gear mechanisms in shape is key for a metal lathe. Follow these simple steps for easy maintenance:

- Clean the gears regularly to remove dust and oil.

- Check for loose parts and tighten them if needed.

- Lubricate with the right oil to keep everything running smoothly.

Watch for signs of trouble. If you hear strange noises or notice uneven cuts, it could mean wear. Seeking professional help early can save you time and money.

How do I know when to get help?

If your lathe is not working well or shows wear signs, consult a mechanic.Regular check-ups ensure your metal lathe runs perfectly. Follow these tips to extend its life and improve efficiency.

User Experiences and Testimonials

Summarized feedback from metal lathe users on gear performance. Case studies showcasing successful projects using specific gear ratios.Many metal lathe users are buzzing about their gear performance. They often say that the right gear ratio makes a big difference in their projects. For example, one user created a stunning clock using a 4:1 gear ratio and raved about how smooth the cuts were. Here’s what some users shared:

| User | Project | Gear Ratio | Feedback |

|---|---|---|---|

| Tom S. | Wooden Bowl | 3:1 | “The precision was a game-changer!” |

| June L. | Metal Gears | 5:1 | “Cut through like butter!” |

| Ravi K. | Art Sculpture | 4:1 | “I could carve my dreams!” |

These stories show how finding the perfect gear ratio can lead to amazing creations and happy users. Always remember, the right gear can make you feel like a metal wizard!

FAQs About Lathe Gear Ratios

Common questions and answers regarding gear ratios in metal lathes. Clarifications on misconceptions related to gear ratios and performance.Many people wonder about lathe gear ratios. One common question is, “What does a gear ratio do?” Well, it helps control the speed of the lathe’s spindle. A higher ratio means more torque, which is fancy talk for power. Some think that higher gear ratios = faster spinning. But hold your horses! That’s only half the story. The type of material you’re cutting also matters.

Here’s a fun fact: A lathe with a gear ratio of 3:1 is like a bike in low gear; you get more pushing power but less speed!

| Gear Ratio | Power | Speed |

|---|---|---|

| 2:1 | Lower | Higher |

| 5:1 | Higher | Lower |

Understanding these ratios helps you choose the right lathe for your projects. So, don’t believe everything you hear about gear ratios. Sometimes, it takes a little math to find the best fit!

Conclusion

In conclusion, understanding lathe gear ratios is crucial for choosing the right metal lathe. Our reviews highlight the best options available. Remember, a proper gear ratio improves performance and precision. You can explore these lathes further to see which fits your needs. Take your time, do research, and find the perfect metal lathe for your projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Reviews:Sure! A lathe is a machine that helps us shape metal. The gear ratio tells us how fast the lathe spins. If the ratio is higher, the lathe goes faster. Reviews of metal lathes help us pick the best one. You should look for a lathe that is easy for you to use and fits your needs.

Sure! Please provide the question you’d like me to answer.

What Is The Significance Of Gear Ratios In Metal Lathes, And How Do They Affect Machining Performance?Gear ratios in metal lathes help us adjust how fast the machine spins. A higher gear ratio means faster spins, which is good for softer materials. A lower gear ratio means slower spins, which works better for harder materials. By changing the gear ratio, we can make sure the lathe cuts smoothly and safely. This helps us make better pieces and keeps the machine working well.

How Can I Determine The Ideal Gear Ratio For Different Types Of Metalworking Projects Using A Lathe?To find the best gear ratio for your metalworking project, start by knowing what you need to do. Different tasks need different speeds. For example, cutting metal may need a slower speed, while polishing needs a faster one. You can look in your lathe’s manual or ask an expert for the right numbers. Experimenting with different settings can also help you see what works best!

What Are Some Highly-Rated Metal Lathes With Adjustable Gear Ratios, And What Features Should I Look For In Reviews?Some highly-rated metal lathes with adjustable gear ratios include the Grizzly G0765 and the JET JWL-1442. When you read reviews, look for details about how easy they are to use. Check if they work quietly and smoothly. You should also see if they have good safety features. Finally, check what other users say about the customer support.

How Do Different Gear Ratios Influence Torque And Spindle Speed In A Metal Lathe?Gear ratios help change how fast and how strong the machine can work. If you use a lower gear ratio, you get more torque, which means more power to cut metal. This makes the spindle (the part that holds the tool) move slower. A higher gear ratio gives you more speed but less torque. This is better when you want to shape the metal quickly but not too deep.

What Are Common Complaints Or Praises Mentioned In Customer Reviews Regarding The Gear Ratio Settings Of Popular Metal Lathes?Many customers praise metal lathes for having good gear ratio settings. This means the machines can spin at different speeds easily. Some people complain that changing speeds can be tricky or slow. Others wish there were more speed options. Overall, most users enjoy the flexibility the settings give them while working.