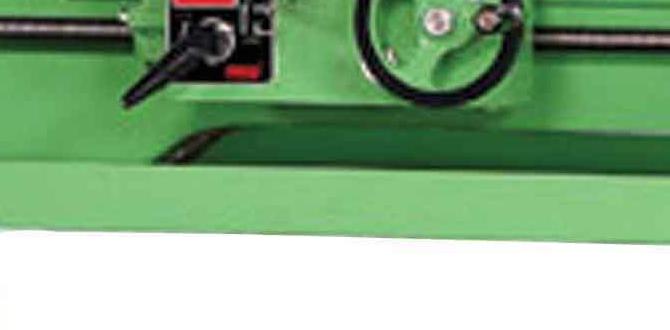

Have you ever wondered how metal lathes work? They might look like big machines, but they are really fascinating! One important part of a metal lathe is the tailstock. It helps to hold pieces in place while they spin. But did you know that the lathe gear ratio plays a crucial role too?

The gear ratio controls how fast the lathe spins. A higher ratio speeds things up, while a lower ratio provides more force. This can change how smooth or rough your final piece turns out. Imagine making a delicate part for a robot! Getting the gear ratio right can make all the difference.

Many hobbyists and experts use metal lathes. They love the feeling of creating something new. Learning about gear ratios can help you become a better maker. So, are you ready to dive deeper into the world of lathes and tailstocks? Let’s explore this exciting topic together!

Understanding Lathe Gear Ratio For Metal Lathe Tailstock

Lathe Gear Ratio and the Metal Lathe Tailstock

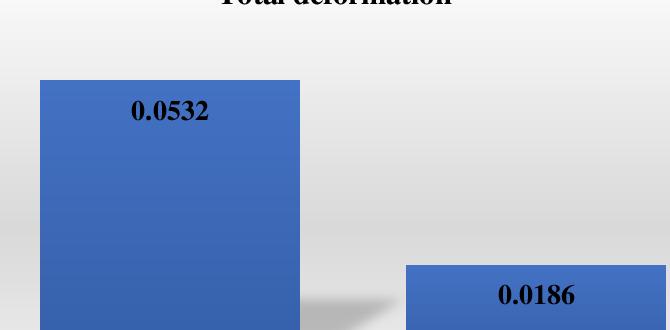

Understanding the lathe gear ratio is key for effective metalworking. It helps determine how fast the lathe spins. A higher gear ratio means more power, which is great for heavy tasks. The tailstock is an important part of a lathe. It supports long materials and ensures precision when drilling or shaping. Did you know that adjusting the tailstock can change the workpiece’s accuracy? Learning how to balance the gear ratio with the tailstock improves your craftsmanship. It’s like finding the perfect rhythm in a dance!What is a Lathe Gear Ratio?

Definition and significance of gear ratios in lathe machinery.. Explanation of how gear ratios affect cutting speeds and torque..A lathe gear ratio tells us how fast the lathe spins and how much power it uses. Think of it like the gears in a bicycle! A high gear means less power but faster speed, while a low gear means more power but slower speed. Gear ratios are super important because they control cutting speeds and torque. If you need to cut hard metal, you want more torque. If you’re smoothing a wooden piece, a faster speed might be better. Here’s a quick look:

| Gear Ratio | Cutting Speed | Torque |

|---|---|---|

| 1:1 | Fast | Low |

| 1:2 | Moderate | Medium |

| 1:4 | Slow | High |

So, next time you’re at the lathe, remember: the right gear ratio can save your day and your metal!

How Gear Ratios Impact Tailstock Functionality

Role of the tailstock in metal lathes and the importance of gear ratios.. Effects of incorrect gear ratios on tailstock performance and accuracy..The tailstock is a key part of metal lathes. It helps hold pieces in place while they are being shaped. Gear ratios play a big role in how well the tailstock works. They control how fast and accurately the tailstock moves.

When gear ratios are wrong, the tailstock can struggle. This can lead to:

- Poor accuracy in cuts

- Difficulty in holding materials

- Increased wear and tear on the machine

Using the right gear ratio ensures steady and precise work. This keeps your projects on track and saves frustration.

What is the role of gear ratios in tailstock function?

Gear ratios determine the speed and control of the tailstock. **A well-set gear ratio leads to smooth operation.** Without it, you might face errors and messy work.

How do incorrect gear ratios affect performance?

- They can result in uneven surfaces.

- Parts may fit poorly together.

- Higher chance of damaging the lathe.

Adjusting Gear Ratios for Optimal Performance

Guidelines for modifying gear ratios in metal lathe setups.. Tips for troubleshooting issues relating to gear ratios and tailstock operations..Adjusting the gear ratios in your metal lathe can improve performance. Here are some guidelines to help you. First, check the manufacturer’s recommendations. This way, you can set the best gear ratio for your projects. Second, if you encounter issues like strange noises or poor cuts, it might be a sign of incorrect gear ratio settings. Review your setup and make adjustments as needed. Remember, a well-adjusted tailstock ensures precise work. Get familiar with these tips for a smoother experience!

What are the main tips for modifying gear ratios?

1. Follow manufacturer instructions.

2. Test different ratios to see what works best.

3. Regularly check for wear and tear on gears.

- Use proper tools to avoid damaging parts.

- Keep the work area clean for safety.

Real-World Applications of Lathe Gear Ratios

Examples of industries and projects where gear ratios play a critical role.. Case studies showcasing the impact of optimized gear ratios on machining efficiency..Think of lathe gear ratios as the magic behind smooth machining. Industries like automotive and aerospace rely heavily on them to create precise parts. For example, when making engine components, optimized gear ratios can speed up production while improving accuracy. A case study in a bike factory showed that tweaking the gear ratio by just a notch slashed production time by 20%! That’s a lot more time for lunch breaks, right?

| Industry | Impact of Gear Ratios |

|---|---|

| Automotive | Enhances precision in engine parts |

| Aerospace | Reduces weight in components |

| Manufacturing | Improves overall efficiency |

Choosing the Right Gear Ratio for Your Metal Lathe

Factors to consider when selecting gear ratios for specific tasks.. Recommendations for ideal setups based on material and project requirements..Choosing the right gear ratio matters for your projects. Different tasks need different settings. Consider these factors:

- Material type: Harder materials need lower ratios for more power.

- Project details: More precision means higher ratios.

- Desired finish: Smooth surfaces require slower speeds.

For most setups, try:

- Wood: Medium ratio (2:1)

- Soft metals: Low ratio (1:2)

- Hard metals: Very low ratio (1:4)

Remember, testing is key! Each project can be a little different.

What is a good gear ratio for different materials?

A suitable gear ratio varies. For wood, use around 2:1. For softer metals, try 1:2. For harder metals, a 1:4 ratio works best.

Maintenance Tips for Tailstock Gear System

Best practices for maintaining gear systems in metal lathes.. Common issues related to wear and tear, and how to prevent them..To keep the tailstock gear system in a metal lathe running well, careful maintenance is key. Here are some helpful tips:

- Regular Cleaning: Use a brush to remove dust and shavings.

- Lubrication: Apply lubricant to moving parts to avoid rust.

- Check Alignment: Make sure all gears are lined up correctly.

- Inspect for Wear: Look for damaged gears and replace them immediately.

Common issues like grinding noise or difficulty moving the tailstock can signal wear or lack of lubrication. Addressing these problems can extend the life of your lathe.

How can I prevent wear in my lathe gears?

Frequent inspections and proper lubrication are essential. Regular checks can spot wear early, while lubrication keeps gears moving smoothly.

Frequently Asked Questions About Lathe Gear Ratios

Answers to common queries regarding gear ratios and tailstock functionalities.. Clarifications on misconceptions surrounding lathe gear systems..Many folks have questions about lathe gear ratios and tailstock functions. For example, some wonder why gear ratios matter. Well, they change the speed and torque of your lathe. More speed can mean quicker jobs, but less torque can lead to problems. The tailstock, on the other hand, helps support long pieces and create precise holes. Confusion often arises between gear ratios and tailstock settings. Remember, one affects cutting while the other is about holding things steady!

| Common Questions | Answers |

|---|---|

| What does a gear ratio do? | It controls the lathe’s speed and power. |

| Why is the tailstock important? | It stabilizes long materials for accurate work. |

Conclusion

In summary, understanding the lathe gear ratio helps you optimize your metal lathe’s performance. The tailstock is crucial for stability and precision in your projects. By adjusting the gear ratio, you can enhance cutting efficiency. Explore your lathe’s manual for specific settings and practice with different ratios. Keep learning, and you’ll become a skilled machinist in no time!FAQs

Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Tailstock:Lathe gear ratios help us turn materials at different speeds. We change the gears to fit what we are making. A lathe’s tailstock helps us hold or support the other end of a piece. This lets us create smooth shapes or holes. Overall, the gear ratio and tailstock work together to make our projects easier and better!

Sure! I can help with that. Just ask your question, and I will answer it simply and clearly.

What Is The Purpose Of The Tailstock On A Metal Lathe, And How Does It Interact With The Lathe’S Gear Ratio?The tailstock on a metal lathe holds tools or materials while we work on them. It helps us make accurate cuts. The tailstock does not directly change the lathe’s gear ratio, which controls how fast the machine spins. Instead, it supports the workpiece, making it easier to cut evenly. This way, we create smoother and better shapes in metal.

How Do You Determine The Correct Gear Ratio Settings When Using A Tailstock For Different Machining Operations?To find the right gear ratio for the tailstock, you need to consider the job you’re doing. First, check the size and type of the material. Then, think about how fast you want to work. You can look at the machine’s guide to see suggested settings. Finally, adjust the gear ratios based on your needs and test it out.

What Are The Advantages Of Using A Power Feed Tailstock On A Metal Lathe Compared To A Manual Feed?Using a power feed tailstock on a metal lathe makes work easier and faster. You can control it with a button instead of pulling a handle. This means you don’t get tired as quickly. It also helps make smoother cuts, which means better results. You can focus more on creating your project instead of worrying about the small movements.

How Can Improper Gear Ratio Adjustments Affect The Performance And Accuracy Of A Metal Lathe When Using The Tailstock?If the gear ratio on a metal lathe isn’t set right, it can cause problems. You might not be able to turn the metal smoothly. This can make your pieces uneven or wonky. It can also affect how tight or loose the tailstock holds the metal. This means your work won’t be as accurate as you want it to be.

What Factors Should Be Considered When Selecting Gear Ratio Options For A Tailstock Application In Precision Machining?When choosing the right gear ratio for a tailstock, think about how fast you want the machine to move. You also need to consider how much power you need to hold the workpiece tightly. Make sure the gear can handle the weight and pressure of what you’re working on. Lastly, check how smooth and precise the movements are for the best results.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Tailstock:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe gear ratios help us turn materials at different speeds. We change the gears to fit what we are making. A lathe’s tailstock helps us hold or support the other end of a piece. This lets us create smooth shapes or holes. Overall, the gear ratio and tailstock work together to make our projects easier and better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I can help with that. Just ask your question, and I will answer it simply and clearly.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Tailstock On A Metal Lathe, And How Does It Interact With The Lathe’S Gear Ratio?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tailstock on a metal lathe holds tools or materials while we work on them. It helps us make accurate cuts. The tailstock does not directly change the lathe’s gear ratio, which controls how fast the machine spins. Instead, it supports the workpiece, making it easier to cut evenly. This way, we create smoother and better shapes in metal.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Gear Ratio Settings When Using A Tailstock For Different Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right gear ratio for the tailstock, you need to consider the job you’re doing. First, check the size and type of the material. Then, think about how fast you want to work. You can look at the machine’s guide to see suggested settings. Finally, adjust the gear ratios based on your needs and test it out.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Power Feed Tailstock On A Metal Lathe Compared To A Manual Feed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a power feed tailstock on a metal lathe makes work easier and faster. You can control it with a button instead of pulling a handle. This means you don’t get tired as quickly. It also helps make smoother cuts, which means better results. You can focus more on creating your project instead of worrying about the small movements.”}},{“@type”: “Question”,”name”: “How Can Improper Gear Ratio Adjustments Affect The Performance And Accuracy Of A Metal Lathe When Using The Tailstock?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the gear ratio on a metal lathe isn’t set right, it can cause problems. You might not be able to turn the metal smoothly. This can make your pieces uneven or wonky. It can also affect how tight or loose the tailstock holds the metal. This means your work won’t be as accurate as you want it to be.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting Gear Ratio Options For A Tailstock Application In Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the right gear ratio for a tailstock, think about how fast you want the machine to move. You also need to consider how much power you need to hold the workpiece tightly. Make sure the gear can handle the weight and pressure of what you’re working on. Lastly, check how smooth and precise the movements are for the best results.”}}]}