Have you ever tried to align the tailstock of a metal lathe? It can be tricky, right? This part is essential for creating precise pieces. A small mistake in tailstock alignment can lead to big errors in your finished work. You might wonder how the lathe gear ratio plays into this. Understanding gear ratios helps make your lathe work better, improving accuracy.

Here’s a fun fact: did you know that just a tiny misalignment can ruin an entire project? Imagine spending hours on a piece only to find it isn’t straight. That’s where the right techniques come into play. In this article, we’ll explore how to achieve perfect tailstock alignment. We’ll also dive into how gear ratios affect your metal lathe’s performance. Let’s unlock the secrets of successful lathe work together!

Lathe Gear Ratio: Metal Lathe Tailstock Alignment Guide

Lathe Gear Ratio and Tailstock Alignment

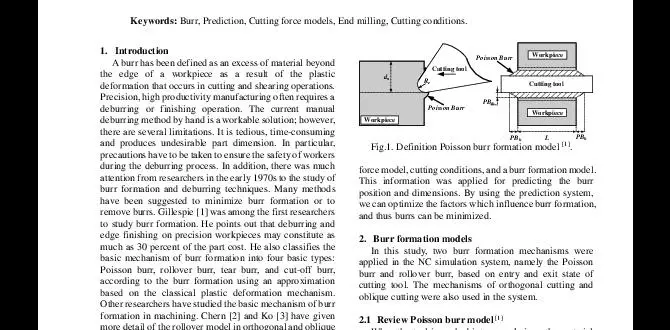

Understanding lathe gear ratio in a metal lathe is essential for smooth operations. Proper gear ratios help control the speed and torque of the lathe. Have you ever noticed how a small change can affect your project? Tailstock alignment is equally important. If misaligned, it can lead to inaccurate cuts and ruined pieces. Did you know that even a tiny error can create big problems? Learning about both elements can improve your skills and outcomes.Understanding Lathe Gear Ratios

Definition and importance of gear ratios in lathe operation.. How gear ratios impact cutting speed and torque..Gear ratios are like magic math behind a lathe. They tell the machine how fast or slow to spin the cutting tool. A higher gear ratio means more speed but less torque, while a lower ratio gives you more torque and less speed. Think of it as a bicycle: you can go fast in a race, but you’ll need to pedal harder up a hill. Understanding these ratios helps you pick the right settings for your projects!

| Gear Ratio | Cutting Speed | Torque |

|---|---|---|

| High Ratio | Fast | Low |

| Low Ratio | Slow | High |

Critical Role of Tailstock in Lathe Operations

Explanation of the tailstock’s function in metal lathing.. Impact of tailstock alignment on machining accuracy..The tailstock is a vital part of a lathe. It holds the end of the workpiece and supports it during machining. This helps in making smooth and accurate cuts. If the tailstock is not aligned correctly, it can cause errors in the workpiece. Misalignments lead to uneven shapes or sizes, making the final product less precise. Proper alignment ensures better performance and accuracy, which is crucial for high-quality results.

How does tailstock alignment affect machining?

Tailstock alignment is essential for achieving accurate cuts and shapes. A well-aligned tailstock can improve overall machining quality, while misalignment can result in wasted materials and time.

Key points on tailstock alignment:

- Ensures straight and smooth cuts.

- Prevents wear and tear on tools.

- Improves overall efficiency in operations.

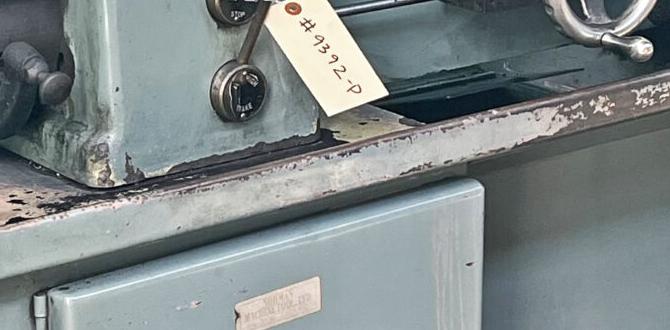

Achieving Accurate Tailstock Alignment

Stepbystep guide to align the tailstock effectively.. Tools and techniques for precise alignment checks..Getting your tailstock aligned is like trying to find that one sock in the laundry—challenging but totally worth it! First, gather your tools: a dial indicator, a measuring gauge, and maybe some snacks. Measure the tailstock’s alignment using the dial indicator, adjusting it until it lines up perfectly. Don’t forget to check the bed for any bumps. If it still looks off, keep tweaking. Remember, patience is key!

Here’s a quick reference table for your alignment tools:

| Tool | Purpose |

|---|---|

| Dial Indicator | Checks alignment accuracy |

| Measuring Gauge | Measures gap distance |

| Wrench | Helps with adjustments |

Once you line it up correctly, your metal lathe will purr like a happy cat! Remember, good alignment leads to better work, and who doesn’t want that?

Common Problems with Tailstock Alignment

Identification of symptoms caused by misalignment.. Troubleshooting tips and solutions for alignment issues..Misaligned tailstocks can cause real headaches. If your workpiece isn’t centered, it may wobble or vibrate like a dancing robot. You might notice uneven cuts or scratches. These are clear signs of trouble. To troubleshoot, check if the tailstock is level. Loosen the screws, adjust it, and tighten them back. A simple ruler can help you measure alignment. If it’s still off, don’t panic—seeking help from a professional is always a good idea!

| Symptoms | Possible Fixes |

|---|---|

| Wobbling workpiece | Adjust tailstock alignment |

| Uneven cuts | Check levelness |

| Scratches on the material | Recalibrate tailstock position |

Best Practices for Gear Ratio Adjustments

Guidelines for adjusting gear ratios for specific projects.. Safety precautions and considerations when modifying gear ratios..Adjusting gear ratios can change how your lathe works. It helps you get the best results for your projects. Here are some simple tips:

- Know your project goals before making any adjustments.

- Always wear safety goggles to protect your eyes.

- Keep hands away from moving parts while adjusting.

- Check for proper alignment after changes.

Remember, taking your time can save you from accidents. A well-adjusted lathe can make your work easier and more fun!

What should I do before adjusting the gear ratios?

Before adjusting gear ratios, you should understand the project requirements. This helps you choose the best ratio for success. Safety is very important in any adjustments.

How can I stay safe while adjusting gear ratios?

To stay safe, always wear safety goggles. Keep tools organized and hands clear from moving parts. Follow the manufacturer’s instructions closely for the best results.

Real-World Applications of Gear Ratios and Tailstock Alignment

Examples of projects benefiting from proper gear ratios and alignments.. Case studies showcasing successful metalworking projects focusing on these elements..Many projects benefit from the right gear ratios and proper tailstock alignment. For example, in a model engine project, precise alignment ensures smooth operation. In a furniture-making task, the correct gear ratio helps achieve the right finish. Check out some amazing projects:

- Model Engines: Improved speed and accuracy.

- Furniture Making: Better fit and finish quality.

- Prototype Parts: High precision and reliability.

These projects highlight how essential these elements are in metalworking. Keeping gear ratios and tailstock aligned can change everything.

What are real-world applications of gear ratios and tailstock alignment?

Real-world applications include machine tool setups, precision crafting, and automotive manufacturing. These areas rely heavily on correct gear ratios and tailstock alignment for efficiency and accuracy.

Resources for Further Learning

Recommended books, articles, and online courses on gear ratios and lathe operations.. Community forums and expert groups for ongoing support and learning..If you want to dive deeper into lathe operations and gear ratios, there are plenty of resources to help you out. Check out some fun books, like “Machining Fundamentals,” which makes learning a breeze. For online courses, platforms like Udemy offer great classes on lathe skills. Jump into community forums, too; they’re treasures of advice. You might even find someone who can teach you how to avoid turning your lathe into a paperweight!

| Resource Type | Recommended Titles |

|---|---|

| Books | “Machining Fundamentals” |

| Online Courses | Udemy Lathe Skills Course |

| Forums | Metalworking Central, Reddit’s r/Machinists |

Conclusion

In conclusion, understanding lathe gear ratios and tailstock alignment is essential for precision machining. These concepts help you create accurate parts. Always check your lathe setup for the best results. By practicing these skills, you can improve your projects. Remember, the more you learn, the better craftsman you’ll become. Keep exploring and enhancing your skills for amazing creations!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Tailstock Alignment:Sure! The gear ratio on a lathe helps you control how fast the machine spins. A higher gear ratio means faster speed. The tailstock of the lathe needs to be aligned properly for accurate work. If it’s not lined up, your parts might not fit right. You can adjust it to make sure it’s straight.

Sure! Please share the question you’d like me to answer.

What Is The Significance Of Gear Ratios In The Operation Of A Metal Lathe, And How Do They Affect Cutting Speed And Torque?Gear ratios in a metal lathe help us control how fast the machine turns. When we change the gear ratio, it changes the cutting speed and the strength, or torque. A higher ratio makes the lathe turn slower but gives more power. A lower ratio makes it turn faster but with less power. This is important to make sure our cuts are smooth and safe.

How Can Misalignment Of The Tailstock Impact The Accuracy Of A Lathe’S Machining Process?If the tailstock on a lathe is not lined up correctly, it can cause problems. You might end up with pieces that are not the right shape or size. This happens because the tool might not touch the material evenly. We need the tailstock to be straight so that everything fits together well. If it’s off, we can make mistakes in our work.

What Are The Steps To Properly Align The Tailstock Of A Metal Lathe For Precision Work?To align the tailstock of a metal lathe, first, you need to check if it is straight. Place a small piece of metal in the chuck at the front. Next, measure the distance from the point of the tool to the center of the tailstock. If it is not the same, you will need to adjust the tailstock until it lines up perfectly. Finally, tighten it up and double-check your measurements to make sure everything is right.

How Can You Determine The Appropriate Gear Ratio For Specific Turning Tasks On A Metal Lathe?To choose the right gear ratio for turning tasks on a metal lathe, we first think about the type of work we need to do. If we want to cut quickly, we need a higher gear ratio. For more detailed or slower work, a lower gear ratio is better. You can check the machine’s manual for the best settings. Always remember to test your settings first to see how they work!

What Are Some Common Symptoms Of Tailstock Misalignment, And How Can They Be Diagnosed And Corrected?Some common signs of tailstock misalignment include uneven cuts and a wobbly piece. You might also see vibrations or hear strange noises while working. To find the problem, you can check the center point between the tailstock and the headstock. If it’s off, you can adjust the tailstock or use a tool to help fix the alignment. This should help your machine work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratio And Metal Lathe Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The gear ratio on a lathe helps you control how fast the machine spins. A higher gear ratio means faster speed. The tailstock of the lathe needs to be aligned properly for accurate work. If it’s not lined up, your parts might not fit right. You can adjust it to make sure it’s straight.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Significance Of Gear Ratios In The Operation Of A Metal Lathe, And How Do They Affect Cutting Speed And Torque?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios in a metal lathe help us control how fast the machine turns. When we change the gear ratio, it changes the cutting speed and the strength, or torque. A higher ratio makes the lathe turn slower but gives more power. A lower ratio makes it turn faster but with less power. This is important to make sure our cuts are smooth and safe.”}},{“@type”: “Question”,”name”: “How Can Misalignment Of The Tailstock Impact The Accuracy Of A Lathe’S Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock on a lathe is not lined up correctly, it can cause problems. You might end up with pieces that are not the right shape or size. This happens because the tool might not touch the material evenly. We need the tailstock to be straight so that everything fits together well. If it’s off, we can make mistakes in our work.”}},{“@type”: “Question”,”name”: “What Are The Steps To Properly Align The Tailstock Of A Metal Lathe For Precision Work?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock of a metal lathe, first, you need to check if it is straight. Place a small piece of metal in the chuck at the front. Next, measure the distance from the point of the tool to the center of the tailstock. If it is not the same, you will need to adjust the tailstock until it lines up perfectly. Finally, tighten it up and double-check your measurements to make sure everything is right.”}},{“@type”: “Question”,”name”: “How Can You Determine The Appropriate Gear Ratio For Specific Turning Tasks On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right gear ratio for turning tasks on a metal lathe, we first think about the type of work we need to do. If we want to cut quickly, we need a higher gear ratio. For more detailed or slower work, a lower gear ratio is better. You can check the machine’s manual for the best settings. Always remember to test your settings first to see how they work!”}},{“@type”: “Question”,”name”: “What Are Some Common Symptoms Of Tailstock Misalignment, And How Can They Be Diagnosed And Corrected?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some common signs of tailstock misalignment include uneven cuts and a wobbly piece. You might also see vibrations or hear strange noises while working. To find the problem, you can check the center point between the tailstock and the headstock. If it’s off, you can adjust the tailstock or use a tool to help fix the alignment. This should help your machine work better!”}}]}