Have you ever wondered how a simple piece of metal can be transformed into an amazing shape? That’s where a lathe comes in. A metal lathe is a powerful machine that helps turn raw metal into finely crafted parts. It does this by spinning the metal and removing bits to create smooth surfaces.

One key to using a lathe is understanding the gear ratio. The gear ratio affects how fast the lathe turns the metal. Imagine trying to ride a bike uphill. You need just the right gear to make it easier. The same idea applies to a lathe. A proper gear ratio helps you achieve the perfect cut.

Taper turning is another exciting feature of a lathe. This technique allows you to create a cone shape, which is useful in many projects. Think about how sharp pencils are made. They often have a tapered end. With a metal lathe and the right gear ratio, you can craft precision shapes.

So, why should you care about lathe gear ratios and taper turning? Because mastering these skills opens a world of possibilities in metalworking. Whether you’re a hobbyist or a professional, these tools can make your projects shine.

Understanding Lathe Gear Ratio For Metal Lathe Taper Turning

Understanding Lathe Gear Ratio for Taper Turning

Discover how lathe gear ratio affects taper turning on a metal lathe. The gear ratio determines the speed of the spindle and the precision of cuts. A correct ratio helps achieve perfect angles and diameters. Have you ever wondered how to make a cone shape? With the right gear settings, it’s simple! Also, knowing gear ratios can save time and improve accuracy in your projects. Mastering this skill opens doors to exciting machining possibilities.What is a Lathe Gear Ratio?

Definition and importance of lathe gear ratios in machining. How gear ratios affect spindle speed and torque.A lathe gear ratio tells us how the motor speed changes when it spins the lathe spindle. It matters a lot in machining. The gear ratio affects two main things: spindle speed and torque. Higher ratios give more speed but less power. Lower ratios provide more power but less speed. Knowing this helps choose the best gear setting for a task. It’s important for making parts smoothly and accurately.

How do gear ratios affect lathe performance?

The right gear ratio can make a difference. A higher gear ratio means faster spindle speeds. This is great for lighter materials. But lower ratios increase torque, which is better for tougher jobs. Choose wisely!

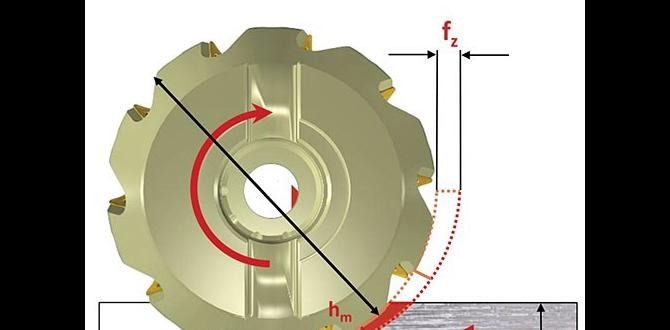

How to Calculate Gear Ratios for Taper Turning

Stepbystep guide on calculating gear ratios for taper turning. Examples of common taper turning applications and gear ratio calculations.Calculating gear ratios for taper turning can be simple and fun. Start by finding the number of teeth on the driving gear and the number on the driven gear. Use this formula: Gear Ratio = Teeth on Driven Gear / Teeth on Driving Gear. For example, if your driving gear has 10 teeth and the driven gear has 40, your gear ratio is 4:1. This means for every turn of the driving gear, the driven gear turns a quarter of a turn. Having the right gear ratio helps create smooth tapers, perfect for crafting beautiful projects!

| Application | Driving Gear Teeth | Driven Gear Teeth | Gear Ratio |

|---|---|---|---|

| Wooden Chair Leg | 10 | 30 | 3:1 |

| Table Lamp Base | 12 | 48 | 4:1 |

Types of Taper Turning Techniques Using Gear Ratios

Different techniques employed in taper turning (e.g., compound rest, taper jig). Relation of gear ratios to each taper turning method.Taper turning techniques help shape materials into cones. Two main methods are the compound rest and the taper jig. Each uses gear ratios to change the lathe’s movement. This makes creating precise tapers easier. Here’s a quick look:

- Compound Rest: Adjusts angle for taper cutting.

- Taper Jig: Guides work for accurate taper shapes.

Understanding lathe gear ratios is key. They determine the power and speed needed for each method. The right ratio helps you cut smoothly, giving the best results.

What are the common taper turning techniques?

Common taper turning techniques include using a compound rest and a taper jig. Both techniques allow for different shapes and sizes of tapers.

Common Gear Ratio Configurations for Metal Lathes

Typical gear ratios used in various lathe models. Pros and cons of different configurations for taper turning.Many metal lathes have common gear ratios. These ratios help in taper turning. Typical gear ratios can range from 1:1 to 4:1. Each gear ratio has its own strengths and weaknesses. Some provide speed, while others offer power and control. Choosing the right ratio affects your project’s results.

- 1:1 Ratio: Good for simple tasks, but lacks speed.

- 2:1 Ratio: Balances speed and torque. Easier for taper work.

- 3:1 Ratio: Offers more power for tougher materials.

- 4:1 Ratio: Best for precise cuts, ideal for detailed work.

Think carefully about your project. Choosing the right gear ratio will lead to better results. It makes taper turning smoother and easier.

How do gear ratios affect taper turning?

Gear ratios affect speed and control during taper turning. A higher ratio means slower speed but more power. A lower ratio allows faster movements but less control.

Choosing the Right Gear Ratio for Your Project

Factors to consider when selecting gear ratios for different taper turning tasks. Tips for optimizing gear ratios for specific materials and cuts.Selecting the right gear ratio is crucial for your taper turning projects. Different tasks need different settings. Here are some key factors to keep in mind:

- Material Type: Softer materials spin easier; harder ones need different ratios.

- Cutting Depth: Deep cuts require a lower ratio for better control.

- Speed: Faster speeds can lead to smoother finishes.

To optimize gear ratios, match them to your material and desired finish. For example, consider using lower ratios for metals and higher for plastics. This approach can help you achieve better results and save time.

What is the best gear ratio for taper turning?

The best gear ratio depends on your project’s specifics. For most taper turning tasks, a range between 2:1 to 4:1 works well. This balance gives you speed and precision.

Troubleshooting Gear Ratio Issues in Lathe Operations

Common problems associated with gear ratios during taper turning. Solutions and adjustments to correct gear ratio issues.When you work with gear ratios in lathe operations, some problems can arise. Common issues include gear slipping or uneven taper shape. These can happen if the gears are worn out or not properly aligned. To fix these problems, you can:

- Check the gear teeth for wear.

- Ensure gears are tightly fitted.

- Adjust the tension in the belts.

Making these adjustments can help keep your lathe running smoothly and improve the quality of your taper turning.

What should I do if my lathe has gear ratio problems?

If you have gear ratio problems, start by inspecting the gears for damage. Tighten any loose parts and adjust your machine settings for better performance.

Future Trends in Lathe Gear Technology

Innovations in gear mechanisms and their potential impact on lathe functionality. Anticipated advancements in gear ratios and taper turning techniques.Many exciting changes are coming in lathe gear technology. New gear mechanisms can make lathes work faster and more smoothly. These innovations might allow for better gear ratios. This change will help with taper turning, making it more precise. As we move forward, we expect big improvements.

- Advanced gear designs can reduce noise and wear.

- New materials may increase durability and efficiency.

- Smart technology could allow for easier adjustments.

What are the anticipated advancements in lathe technology?

Future advancements in lathe technology focus on efficiency and precision. Expect enhancements in gear ratios that improve machining speed. Additionally, taper turning techniques will become more accurate, making it easier for users.

Conclusion

In summary, understanding lathe gear ratios is essential for effective taper turning. These ratios affect your machine’s speed and precision. By learning how to adjust them, you can improve your projects. If you’re interested in metalworking, practice using different gear ratios. For more tips, consider reading beginner guides or watching tutorials to enhance your skills further.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios And Taper Turning On A Metal Lathe:Sure! Here are some answers about lathe gear ratios and taper turning: 1. **What is a gear ratio?** A gear ratio is like a teamwork number. It tells us how fast one gear turns compared to another. 2. **How do we use gear ratios on a lathe?** We use gear ratios to change the speed of the lathe. This helps us cut different shapes and sizes. 3. **What is taper turning?** Taper turning means making one end of something smaller than the other. It helps create fun shapes like cones. 4. **Why is taper turning important?** Taper turning is important because it helps fit parts together. It can also help make things look nicer. 5. **What safety tips do we need for using a lathe?** Always wear safety glasses and keep your hands clear. Pushing too hard can be dangerous, so be careful!

Sure! Just go ahead and ask your question, and I’ll be happy to help you with a short answer.

What Is The Importance Of Gear Ratios In A Metal Lathe, And How Do They Affect Cutting Speed And Torque?Gear ratios in a metal lathe help control how fast the machine turns. When we change the gear ratio, it affects the cutting speed and the power, called torque. A higher gear ratio gives more speed but less power. A lower gear ratio gives more power but less speed. Using the right gear ratio helps us get the best results while cutting metal.

How Is Taper Turning Achieved On A Metal Lathe, And What Adjustments Need To Be Made To The Gear Ratio For Different Tapers?You can make a taper on a metal lathe by changing the angle of the tool. First, you adjust the tool holder so it’s tilted. This angle makes one end of the piece smaller than the other. To change the taper size, you might need to change the gear ratio, which controls the speed of the lathe. This helps you make different slants on your metal piece.

What Are The Common Methods Of Taper Turning On A Metal Lathe, And How Do Gear Ratios Influence Each Method?We can use different methods to turn a taper on a metal lathe. One way is to set the tailstock at an angle. Another way is to move the compound rest at a slant. Gear ratios are important because they help control the speed and force of the lathe. When we change the gear ratio, we can make the taper smoother or faster.

How Can A Machinist Calculate The Required Gear Ratio For A Specific Taper Angle When Setting Up A Metal Lathe?To find the right gear ratio for a taper angle, you first need to know the angle you want. Then, you can use a formula that connects the angle to the ratio. For example, you divide the angle by a number related to the lathe. After you calculate that, you set the gears on the lathe to match it. This way, you make the taper correctly!

What Types Of Gear Systems Are Typically Used In Metal Lathes For Taper Turning, And How Do They Compare In Terms Of Efficiency And Precision?In metal lathes for taper turning, we usually see gear systems like the compound rest and taper attachment. The compound rest helps you quickly change the angle for different shapes. The taper attachment allows you to make long and accurate tapered pieces. Both are efficient but can vary in precision; the taper attachment is more accurate for longer taps. You can choose based on what you need to create!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gear Ratios And Taper Turning On A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers about lathe gear ratios and taper turning: 1. **What is a gear ratio?** A gear ratio is like a teamwork number. It tells us how fast one gear turns compared to another. 2. **How do we use gear ratios on a lathe?** We use gear ratios to change the speed of the lathe. This helps us cut different shapes and sizes. 3. **What is taper turning?** Taper turning means making one end of something smaller than the other. It helps create fun shapes like cones. 4. **Why is taper turning important?** Taper turning is important because it helps fit parts together. It can also help make things look nicer. 5. **What safety tips do we need for using a lathe?** Always wear safety glasses and keep your hands clear. Pushing too hard can be dangerous, so be careful!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just go ahead and ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Is The Importance Of Gear Ratios In A Metal Lathe, And How Do They Affect Cutting Speed And Torque?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratios in a metal lathe help control how fast the machine turns. When we change the gear ratio, it affects the cutting speed and the power, called torque. A higher gear ratio gives more speed but less power. A lower gear ratio gives more power but less speed. Using the right gear ratio helps us get the best results while cutting metal.”}},{“@type”: “Question”,”name”: “How Is Taper Turning Achieved On A Metal Lathe, And What Adjustments Need To Be Made To The Gear Ratio For Different Tapers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make a taper on a metal lathe by changing the angle of the tool. First, you adjust the tool holder so it’s tilted. This angle makes one end of the piece smaller than the other. To change the taper size, you might need to change the gear ratio, which controls the speed of the lathe. This helps you make different slants on your metal piece.”}},{“@type”: “Question”,”name”: “What Are The Common Methods Of Taper Turning On A Metal Lathe, And How Do Gear Ratios Influence Each Method?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use different methods to turn a taper on a metal lathe. One way is to set the tailstock at an angle. Another way is to move the compound rest at a slant. Gear ratios are important because they help control the speed and force of the lathe. When we change the gear ratio, we can make the taper smoother or faster.”}},{“@type”: “Question”,”name”: “How Can A Machinist Calculate The Required Gear Ratio For A Specific Taper Angle When Setting Up A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right gear ratio for a taper angle, you first need to know the angle you want. Then, you can use a formula that connects the angle to the ratio. For example, you divide the angle by a number related to the lathe. After you calculate that, you set the gears on the lathe to match it. This way, you make the taper correctly!”}},{“@type”: “Question”,”name”: “What Types Of Gear Systems Are Typically Used In Metal Lathes For Taper Turning, And How Do They Compare In Terms Of Efficiency And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes for taper turning, we usually see gear systems like the compound rest and taper attachment. The compound rest helps you quickly change the angle for different shapes. The taper attachment allows you to make long and accurate tapered pieces. Both are efficient but can vary in precision; the taper attachment is more accurate for longer taps. You can choose based on what you need to create!”}}]}