Have you ever wondered how a lathe works? It’s a fascinating machine that shapes metal into useful parts. But there’s more to it than meets the eye. One important concept is the lathe gear ratio.

The gear ratio affects how much torque a lathe can produce. Torque is the force that allows the machine to turn and shape the metal. A higher gear ratio gives more power, which means it can handle tougher materials.

Imagine trying to cut a thick piece of steel. If your lathe has the right gear ratio, it makes the job easier. But what if it doesn’t? You might struggle and get poor results.

Here’s a fun fact: Many professional machinists consider gear ratio to be a key part of their work. A good understanding of lathe gear ratios can lead to better projects and more efficient work.

In this article, we will explore the importance of lathe gear ratios, how they affect torque, and why every metal lathe user should know about them. Ready to dive in?

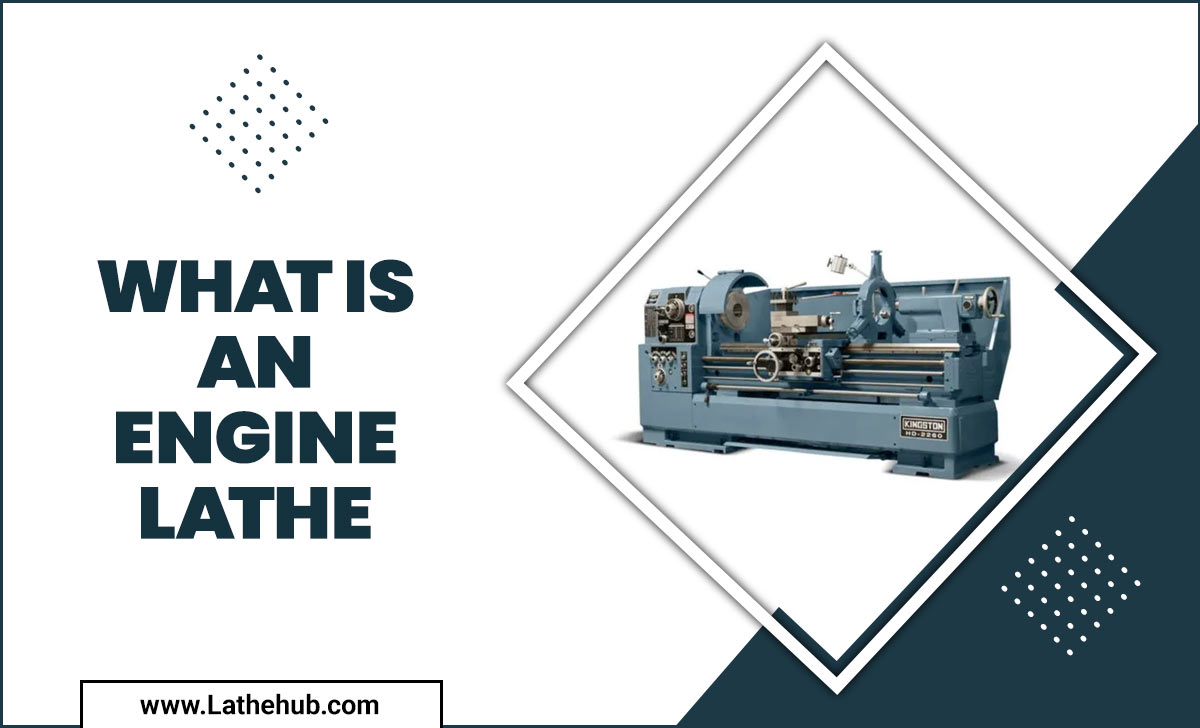

Understanding Lathe Gear Ratio For Metal Lathe Torque

Understanding Lathe Gear Ratio, Metal Lathe, and Torque

Lathe gear ratio influences the speed and power of a metal lathe. A higher gear ratio usually means more torque, which helps cut through tough materials. Imagine trying to slice a thick cake; more force makes it easier, right? Gear ratios also affect the lathe’s precision and finish quality. Understanding this concept lets you choose or adjust your lathe for better results. Knowing how gear ratios work might just make your next project smoother!What is Gear Ratio in Metal Lathes?

Definition and importance of gear ratios in lathes. Explanation of how gear ratio affects lathe performance.The gear ratio in a metal lathe is a magic number. It tells you how many times the motor spins compared to the spindle. This is important because it affects the lathe’s performance. A higher gear ratio gives more torque, which is the twisting power to cut metal. Imagine trying to turn a stubborn screw with a tiny screwdriver! The right gear ratio makes everything much smoother.

| Gear Ratio | Torque Output |

|---|---|

| 1:1 | Low |

| 3:1 | Higher |

| 5:1 | Even Higher |

In summary, understanding gear ratios helps you pick the right settings for your job. It’s like choosing the right bike gear to climb a hill—too easy and you won’t get anywhere, too hard and you’ll tire out!

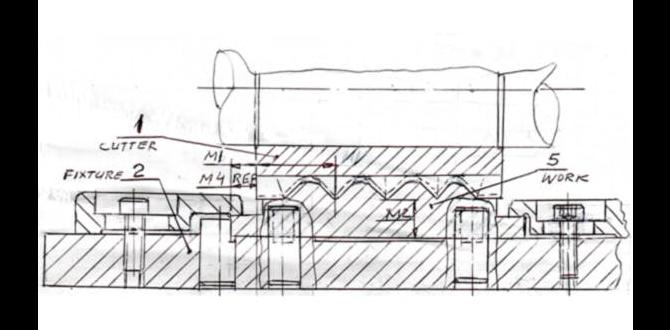

Calculating Gear Ratios for Metal Lathes

Stepbystep guide to calculating gear ratios. Key factors to consider when calculating gear ratios.Calculating gear ratios for metal lathes can seem tricky, but it’s as easy as pie, or maybe easier! First, you measure the number of teeth on your gear. The gear ratio is found by comparing the driving gear to the driven gear. Here’s a quick guide:

| Step | Action |

|---|---|

| 1 | Count the teeth on both gears. |

| 2 | Divide the teeth of driving gear by the driven gear. |

| 3 | That’s your ratio! Remember, higher numbers mean more torque. |

Key factors include the type of material you’re working with and the desired speed. A lower gear ratio gives you more torque but less speed. Conversely, a higher ratio yields more speed but less torque. Think of it like a turtle and a rabbit in a race—who’s going to win depends on your goals!

The Relationship Between Gear Ratio and Torque

Explanation of how gear ratio influences torque output. Examples of gear ratio adjustments and their torque implications.The gear ratio plays a big role in how much torque a lathe can produce. Gear ratio tells us how fast the lathe spins compared to the motor. A higher gear ratio can give more power or torque, while a lower ratio can make the lathe spin faster but with less torque. For example, if we change the gear from 1:1 to 2:1, we get double the torque. This helps in working with tougher materials.

- High Gear Ratio (2:1): More torque, less speed.

- Low Gear Ratio (1:2): More speed, less torque.

So, adjusting the gear ratio affects the power and speed, helping you do different jobs better.

How does gear ratio affect torque?

Gear ratio affects the balance between speed and torque in a lathe. Higher ratios mean more torque for tougher tasks, while lower ratios favor speed for lighter jobs.

Adjusting Gear Ratios for Enhanced Performance

Methods to modify gear ratios in metal lathes. Recommendations for adjusting ratios based on material types and projects.Tweaking gear ratios can turn your metal lathe into a real powerhouse. You can change these ratios by swapping out gears or using a different speed setting. For softer materials, like aluminum, go for a higher ratio to keep things smooth. But when tackling tough steel, lower the ratio to boost torque. Remember, with great power comes great… well, torque! It’s all about matching the ratio to the job.

| Material Type | Recommended Gear Ratio |

|---|---|

| Aluminum | High Ratio |

| Steel | Low Ratio |

| Bronze | Medium Ratio |

Impact of Gear Ratio on Machining Efficiency

Discussion of how gear ratios affect feed rates and cutting speeds. Analysis of efficiency gains achieved through optimal gear ratio selection.Gear ratios play a key role in machining efficiency. They influence how fast the feed rates and cutting speeds are during operation. A higher gear ratio means quicker cutting movements, speeding up work. Picking the right gear ratio can lead to big gains in efficiency. With the correct settings, machines use less energy and provide smoother finishes. This not only saves time but also reduces wear and tear on the tools.

How do gear ratios affect cutting speeds?

Gear ratios change the speed of the lathe and the cutting tools. A higher gear ratio increases cutting speed, while a lower ratio offers more control.

Quick Points:

- Higher ratio = faster cutting

- Lower ratio = better control

- Optimal ratios improve overall efficiency

Common Mistakes in Gear Ratio Selection

Highlight frequent errors when choosing gear ratios. Tips to avoid these pitfalls for better performance.Choosing the right gear ratio can feel like trying to pick the best ice cream flavor—so many options! Some common mistakes include picking ratios that are too high or too low. This can lead to weak torque or slow performance, and nobody wants a lazy lathe! To avoid these blunders, always check the specs of your machinery. Remember, balance is key! And hey, don’t forget to ask for advice; even the best chefs don’t cook alone!

| Mistakes | Tips |

|---|---|

| Choosing a high gear ratio | Check machine specifications to ensure torque is sufficient. |

| Ignoring load capacity | Always consider the maximum load your lathe can handle. |

| Not testing various ratios | Experiment to find the best fit for your projects! |

Future Trends in Gear Ratio Technology for Metal Lathes

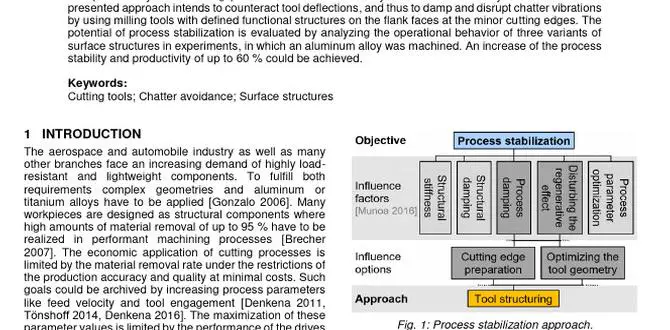

Exploration of emerging technologies affecting gear ratios. Predictions for the future of lathe technology related to gear ratios and torque.New technologies are changing gear ratios in metal lathes. Smart sensors now help measure torque better. This means lathes can operate more efficiently. We can expect two main trends in the future:

- Improved automation: Machines will adjust gear ratios automatically based on the task.

- Advanced materials: Lighter, stronger materials will enhance performance and reduce wear.

With these changes, metal lathes will become smarter and more powerful. They will help create more precise workpieces in less time. It’s an exciting time for lathe technology!

What are the future trends in lathe technology?

Future trends include better automation and the use of advanced materials. These improvements will enhance both gear ratio performance and overall machinery efficiency.

Conclusion

In conclusion, understanding lathe gear ratios helps you control torque effectively. A higher gear ratio increases torque, making tough tasks easier. You should always match gear settings to your project needs. Remember to experiment and practice with your metal lathe to improve your skills. If you’re curious, explore more on lathe mechanics for deeper learning!FAQs

What Is The Importance Of Gear Ratio In Determining The Torque Output Of A Metal Lathe?The gear ratio tells us how much power the lathe can use to spin. A higher gear ratio gives more torque, which helps cut harder materials. This means you can do tougher jobs more easily. If the gear ratio is low, the machine spins faster but cuts less powerfully. So, it’s important to choose the right gear ratio for the task.

How Do Different Gear Ratios Affect The Cutting Speed And Torque On A Metal Lathe?Different gear ratios change how fast the lathe cuts metal. A high gear ratio makes the lathe spin faster and cuts quicker. This is good for thin materials. A low gear ratio offers more torque, which means it can push harder through thick metal. We need to pick the right gear ratio for the job!

What Calculations Are Necessary To Determine The Ideal Gear Ratio For Specific Machining Tasks On A Metal Lathe?To find the right gear ratio for a metal lathe, you need to know two things: the speed of the motor and the speed you want for the tool. First, measure the motor speed in revolutions per minute (RPM). Then, decide how fast you want the tool to turn. You can calculate the gear ratio by dividing the motor speed by the tool speed. This tells you how many times the motor turns for each turn of the tool.

How Can Adjusting The Gear Ratio On A Metal Lathe Influence The Quality Of The Finished Product?Adjusting the gear ratio on a metal lathe changes how fast the machine spins. When you pick the right speed, you get a smoother finish. If it spins too fast, it can cause mistakes. If it spins too slow, it might take longer. So, finding the best speed helps you make better products!

What Are The Potential Consequences Of Using An Incorrect Gear Ratio In Terms Of Torque And Performance On A Metal Lathe?Using the wrong gear ratio on a metal lathe can cause problems. You might not get enough power or torque, which makes it hard to cut metal. This can lead to bad cuts or even break the tools. If the lathe spins too fast, it can make your work unsafe and messy. Using the right gear ratio helps keep everything running smoothly.