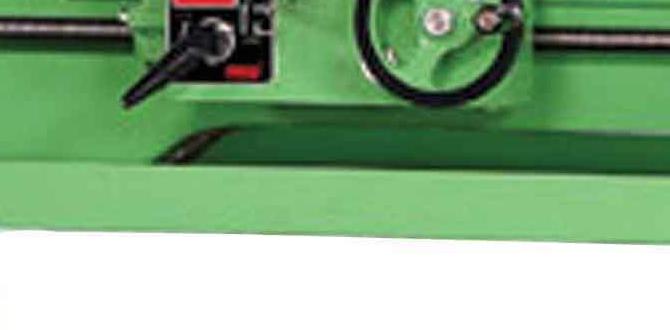

Have you ever wondered how metal working machines operate smoothly? One key element is the lathe gear ratio. This ratio helps control the speed and torque of the lathe. But how does it all fit together?

Understanding the metal lathe wiring diagram can seem tricky. However, once you grasp the basics, it becomes simple. Imagine building a machine that shapes metal precisely. You’d want to know how each part works, right?

Here’s a fun fact: the right gear ratio can make a huge difference in your project. It can speed up your work or give you more power when needed. Understanding this makes you a better builder and creator.

In this article, we will explore lathe gear ratios and wiring diagrams. We’ll break it down step by step. By the end, you’ll feel like a pro. Ready to dive in and learn more?

Lathe Gear Ratio: Understanding Metal Lathe Wiring Diagram

Understanding Lathe Gear Ratio and Wiring

Learning about lathe gear ratio and metal lathe wiring diagrams reveals key aspects of woodworking and metalwork. A lathe’s gear ratio affects speed and torque, making it vital for different tasks. Curious how gear adjustments influence cuts? With a proper wiring diagram, you can easily set up your lathe for optimal performance. Did you know a small change in gear ratio can drastically alter your project’s outcome? Understanding these elements boosts your skills and results!What is Gear Ratio in Metal Lathes?

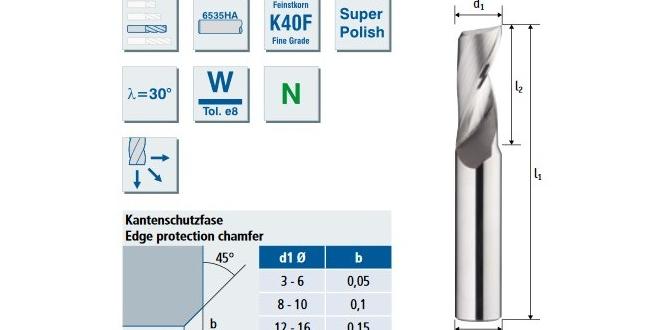

Definition of gear ratio and its significance in metal lathes. How gear ratio affects cutting speed and torque.Gear ratio is a way to compare the speeds of two gears in a machine. In metal lathes, it matters because it affects how fast the tool can cut and how much force it can use. A higher gear ratio means the lathe can cut at a slower speed with more torque. This is useful for hard materials. In contrast, a lower gear ratio allows for faster cutting speeds but with less torque. Understanding this helps users choose the right settings for their project.

What does gear ratio do in metal lathes?

Gear ratio changes the cutting speed and torque. A higher ratio gives more power for tough jobs, while a lower ratio speeds up the process. Knowing how they work helps workers make the best choices.

Key Points:

- Higher gear ratio = more torque

- Lower gear ratio = faster speed

Calculating Gear Ratio for Metal Lathes

Stepbystep guide on calculating gear ratios. Example calculations for different lathe models.To calculate the gear ratio for metal lathes, follow these steps:

- Identify the number of teeth on the drive gear.

- Count the teeth on the driven gear.

- Use the formula: Gear Ratio = Teeth on Driven Gear / Teeth on Drive Gear.

For example:

- Lathe Model A: 20 teeth drive gear and 60 teeth driven gear. Gear ratio = 60/20 = 3.

- Lathe Model B: 30 teeth drive gear and 90 teeth driven gear. Gear ratio = 90/30 = 3.

This helps you understand the machine’s speed and torque. Knowing these ratios makes working with metal lathes easier!

What is a gear ratio?

A gear ratio is the relationship between the number of teeth on two gears that are connected. It impacts how fast a machine runs.

Importance of Gear Ratio in Machining

Impact of gear ratio on machining accuracy and efficiency. How different applications require specific gear ratios.Gear ratio plays a big role in how machines work. It affects both accuracy and efficiency. A proper gear ratio leads to smoother operations and better results. For different jobs, different gear ratios are needed. For example, a higher ratio helps cut through tough materials. Meanwhile, a lower ratio increases speed for simpler tasks.

- Higher gear ratios = More torque, less speed

- Lower gear ratios = More speed, less torque

Choosing the right ratio boosts production and reduces waste.

Why is gear ratio important in machining?

Gear ratio impacts both the accuracy of cuts and the overall efficiency of operations.

What are the applications for specific gear ratios?

- Heavy machining needs higher ratios for power.

- Precision work requires lower ratios for accuracy.

Interpreting a Metal Lathe Wiring Diagram

Key symbols and terms in wiring diagrams. How to read and understand a typical wiring diagram.Reading a metal lathe wiring diagram can feel like deciphering a treasure map, but it’s actually quite straightforward. Key symbols show you where wires go and what each part does. Familiarize yourself with simple terms like volt and ground. When you see lines connecting components, they indicate a connection. Don’t let it confuse you! It’s like a game of connect-the-dots. Understanding these parts makes the process much easier—and much less like a puzzle without a picture!

| Symbol | Meaning |

|---|---|

| V | Voltage |

| GND | Ground |

| AC | Alternating Current |

| DC | Direct Current |

Common Issues with Gear Ratios and Wiring

Troubleshooting common gear ratiorelated problems. Electrical issues related to wiring in metal lathes.Metal lathes can be tricky little machines. Sometimes, the gear ratios cause strange problems. If your lathe speeds up or slows down unexpectedly, the gear ratio might be off. You might need to check the settings or ensure the gears are aligned. Electrical issues also pop up. Wires might get loose, causing the motor to stall. Always check connections! Here’s a quick table for common problems:

| Problem | Solution |

|---|---|

| Misaligned gears | Adjust the gear settings |

| Loose wiring | Tighten all connections |

| Motor not running | Check power supply |

Stay sharp with troubleshooting, and your lathe will be as smooth as butter!

Upgrading Gear Ratio and Wiring Systems

Benefits of upgrading gear ratios for performance. Tips for modernizing wiring systems for safety and efficiency.Upgrading gear ratios can immensely boost your lathe’s performance. Higher gear ratios provide more torque, allowing for smoother cutting and better results. It can also speed up machining times, helping you finish projects faster. Modernizing wiring systems ensures safety and improves efficiency. Using newer wiring reduces the risk of shorts and fires. Here are some tips:

- Use high-quality wires for better conductivity.

- Install fuses to protect against overload.

- Keep connections clean and tight.

Take these steps to enhance your lathe experience!

What are the benefits of upgrading gear ratios?

Upgrading gear ratios improves performance, increases torque, and reduces machining time.What should you consider when modernizing wiring systems?

Focus on safety, use quality materials, and ensure tidy connections.Resources for Further Learning

Recommended books and online resources on lathe maintenance. Forums and communities for lathe enthusiasts and operators.Learning about lathe maintenance can be fun and helpful. Check out these books and online resources:

- The Complete Manual of Woodworking – Offers great tips.

- Lathe Fundamentals – Perfect for beginners.

- Online forums – Join communities like Practical Machinist or Reddit’s Machining for support.

These resources can help you become a better lathe operator.

What are some good books for lathe maintenance?

Some recommended titles include Lathe Handbook and Essential Lathe Techniques. They offer hands-on advice and tips.

Conclusion

In conclusion, understanding the lathe gear ratio helps you control speed and torque. A clear wiring diagram is essential for safe setup and operation. Use this knowledge to improve your metalworking skills. If you’re eager to learn more, explore tutorials online or ask experienced makers for tips. Happy turning!FAQs

What Is The Importance Of Gear Ratio In Metal Lathes, And How Does It Affect Machining Performance?Gear ratio in metal lathes is important because it controls the speed and power of the machine. A good gear ratio helps the lathe cut metal smoothly and easily. If the ratio is too high, it can go too fast and mess things up. If it’s too low, it might struggle to cut. We want the right gear ratio for the best work.

How Do I Read And Understand A Wiring Diagram For A Metal Lathe, Specifically In Relation To Its Gear System?To read a wiring diagram for a metal lathe, look at the lines and symbols. Lines show wires, and symbols show parts like gears. You need to find where the gears connect to the motor. Follow the lines to see how electricity flows. This helps you understand how the gear system works together.

What Are The Common Gear Ratios Used In Metal Lathes, And How Do They Influence Cutting Speed And Torque?Common gear ratios in metal lathes include 1:1, 2:1, and 4:1. These numbers tell you how fast the cutting tool spins. For example, a 2:1 ratio makes it spin faster, which helps cut quickly. But a 4:1 ratio gives more power, making it easier to cut tough metal. So, the right gear ratio helps you cut better!

Can You Provide Step-By-Step Instructions On How To Adjust The Gear Ratio On A Typical Metal Lathe?To adjust the gear ratio on a metal lathe, follow these steps: 1. First, turn off the lathe and unplug it for safety. 2. Open the cover to find the gears inside. 3. Look for the gear ratio settings; they are usually marked with numbers. 4. Loosen the screws holding the gears in place. 5. Move the gears to the desired position and tighten the screws. 6. Close the cover and plug in the lathe again. You’re now ready to use your metal lathe with the new gear ratio!

What Safety Precautions Should Be Taken When Working With The Wiring And Gear Systems Of A Metal Lathe?When using a metal lathe, always unplug it before working on the wiring. Make sure to wear safety goggles to protect your eyes. Keep your hands away from moving parts to avoid injuries. Check for any loose wires or parts, and fix them before starting. Lastly, remember to follow the instructions and ask for help if you’re unsure.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Importance Of Gear Ratio In Metal Lathes, And How Does It Affect Machining Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Gear ratio in metal lathes is important because it controls the speed and power of the machine. A good gear ratio helps the lathe cut metal smoothly and easily. If the ratio is too high, it can go too fast and mess things up. If it’s too low, it might struggle to cut. We want the right gear ratio for the best work.”}},{“@type”: “Question”,”name”: “How Do I Read And Understand A Wiring Diagram For A Metal Lathe, Specifically In Relation To Its Gear System? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To read a wiring diagram for a metal lathe, look at the lines and symbols. Lines show wires, and symbols show parts like gears. You need to find where the gears connect to the motor. Follow the lines to see how electricity flows. This helps you understand how the gear system works together.”}},{“@type”: “Question”,”name”: “What Are The Common Gear Ratios Used In Metal Lathes, And How Do They Influence Cutting Speed And Torque? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common gear ratios in metal lathes include 1:1, 2:1, and 4:1. These numbers tell you how fast the cutting tool spins. For example, a 2:1 ratio makes it spin faster, which helps cut quickly. But a 4:1 ratio gives more power, making it easier to cut tough metal. So, the right gear ratio helps you cut better!”}},{“@type”: “Question”,”name”: “Can You Provide Step-By-Step Instructions On How To Adjust The Gear Ratio On A Typical Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the gear ratio on a metal lathe, follow these steps: 1. First, turn off the lathe and unplug it for safety. 2. Open the cover to find the gears inside. 3. Look for the gear ratio settings; they are usually marked with numbers. 4. Loosen the screws holding the gears in place. 5. Move the gears to the desired position and tighten the screws. 6. Close the cover and plug in the lathe again. You’re now ready to use your metal lathe with the new gear ratio!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working With The Wiring And Gear Systems Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always unplug it before working on the wiring. Make sure to wear safety goggles to protect your eyes. Keep your hands away from moving parts to avoid injuries. Check for any loose wires or parts, and fix them before starting. Lastly, remember to follow the instructions and ask for help if you’re unsure.”}}]}