Have you ever wondered how machines make perfect gears? A lathe is one of the tools that help create these amazing parts. But there’s a trick to it: the gear tooth pitch calculation.

Pitch sounds fancy, but it’s really just a way to measure the distance between teeth on a gear. Why does this matter? Well, if the teeth are not spaced right, gears won’t fit together properly, and they can break!

Imagine trying to fit puzzle pieces that don’t match. It’s frustrating, right? The same goes for gears. Understanding lathe gear tooth pitch calculation helps makers avoid this problem.

Did you know that one small mistake in pitch can throw off the entire machine? That’s why every detail matters. In this article, we will explore the basics of gear tooth pitch and how to calculate it step by step. Get ready to dive into the world of gears! You might just discover a new hobby!

Lathe Gear Tooth Pitch Calculation: Essential Guide Explained

Lathe Gear Tooth Pitch Calculation

Calculating the tooth pitch for lathe gears is essential for smooth operation. Did you know that inaccurate calculations can lead to poor gear performance? First, understand that tooth pitch measures the distance between gears. Next, use the formula: Pitch = Circumference / Number of Teeth. This helps determine the right spacing. Knowing this can save time and enhance your project’s precision. It’s a small detail that makes a big difference in gear efficiency!Understanding Gear Tooth Pitch

Definition of gear tooth pitch. Importance of calculating gear tooth pitch in machining.Gear tooth pitch is the distance between the center of one tooth and the center of the next. Think of it as the space in between the teeth on a gear, which helps them fit together smoothly. Calculating gear tooth pitch in machining is vital because it ensures gears mesh correctly. If the pitch is off, you might end up with a noisy gear that sounds like a cat trying to sing! Accurate calculations lead to better performance and less wear and tear.

| Term | Definition |

|---|---|

| Gear Tooth Pitch | Distance between centers of adjacent gear teeth. |

| Importance | Ensures proper meshing and smooth operation. |

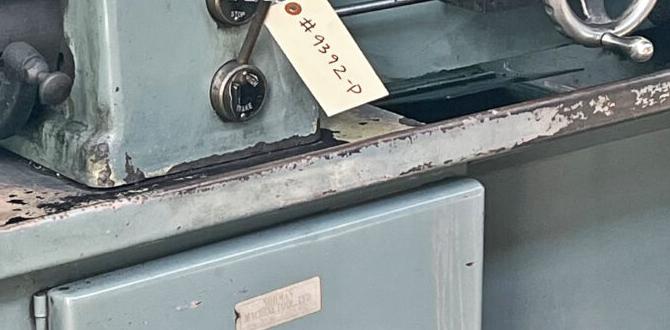

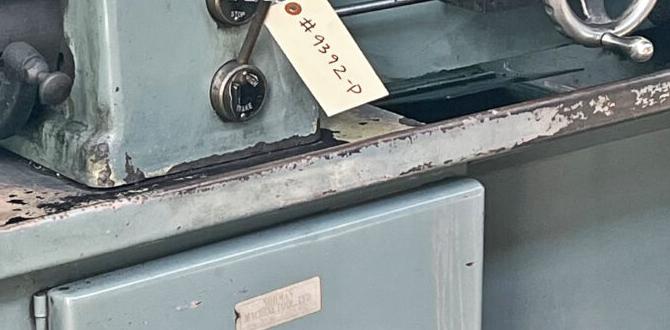

The Role of Lathe in Gear Manufacturing

How lathes are used in gear production. Types of lathes suited for gear manufacturing.Lathes are important in making gears. They help shape and cut metal into round parts. These machines spin the metal while a cutting tool shapes it. This process creates precise gear teeth. Different lathes are used for gear production. Some common types include:

- Engine Lathes: Great for small to medium gears.

- CNC Lathes: Perfect for complex shapes and high efficiency.

- Specialized Lathes: Designed specifically for gear making.

With these tools, manufacturers create strong and accurate gears for many machines.

What are the benefits of using a lathe in gear production?

Using a lathe helps create precise gear designs, saves time, and improves production consistency. This makes the gears last longer and work better in machines.

Step-by-Step Guide to Calculate Tooth Pitch

Required tools and materials for calculation. Formula for calculating tooth pitch.Calculating tooth pitch is simple if you have the right tools. You’ll need a ruler, a calculator, and a piece of paper. These help you find the gear’s size and distance between teeth.

Use this formula to find tooth pitch: Pitch = (Number of Teeth / Diameter). This tells you how far apart each tooth is on the gear. It’s like measuring space between your fingers!

- Ruler

- Calculator

- Paper

Factors Affecting Gear Tooth Pitch Calculation

Influence of gear material and size. Effects of manufacturing tolerances on tooth pitch.Several factors can change how we calculate gear tooth pitch. The type of material used to make the gear can affect strength and wear. Bigger gears need different calculations compared to smaller ones. Also, manufacturing tolerances play a big role. If the parts aren’t made exactly right, the tooth pitch might change. This can lead to issues in how the gears fit and work together.

What materials affect gear tooth pitch?

Metal materials like steel or aluminum usually make stronger gears. Using good materials helps keep the gears working well.

Effects of Manufacturing Tolerances:

- Small errors can change the tooth pitch.

- Adjustments are needed for better fitting.

- More precise tools help reduce errors.

Applications of Gear Tooth Pitch Calculations

Industries that rely on accurate pitch calculation. Realworld examples of applications in machinery.Many industries depend on precise gear tooth pitch calculations. These calculations are vital for machines that need to work smoothly. For example, cars use gears for smooth driving. Any mistake in pitch could lead to clunky rides or even breakdowns! Did you know? The aerospace industry also relies on accurate pitch for safe aircraft operation. In the manufacturing world, gears help machines run efficiently. Without proper calculations, machines might run like a turtle on roller skates!

| Industry | Application |

|---|---|

| Automotive | Gear systems for smooth operation |

| Aerospace | Critical for aircraft safety |

| Manufacturing | Efficient operation of machinery |

Advanced Techniques and Tools for Accurate Calculation

Review of software and tools for gear design. Tips for precision in pitch calculations using technology.Using the right tools makes lathe gear tooth pitch calculation easier and more accurate. Several software options can help. These include gear design programs that automatically calculate pitch. Tips for precision include:

- Always double-check measurements.

- Use high-quality materials to avoid errors.

- Stay updated on the latest software updates.

Many engineers find using these tools saves time and improves accuracy. Always remember that a small mistake can lead to bigger problems later.

What software is best for gear design?

Popular software includes AutoCAD and SolidWorks. They provide great features for gear calculations.

Resources for Further Learning

Books and online courses on gear design. Communities and forums for gear engineering discussions.Learning about gears can be exciting! Here are some great places to boost your knowledge:

- Look for books on gear design in libraries or bookstores.

- Try online courses that focus on gear engineering.

- Join communities or forums where people discuss gear topics.

- Watch video tutorials to see real-life examples.

These resources can help deepen your understanding and make gear design fun!

What are some good resources for gear design?

Books, online courses, and forums are great tools to explore gear design.

Conclusion

In summary, calculating lathe gear tooth pitch is essential for smooth gear operation. We learned that pitch refers to the distance between teeth. You can use simple formulas to find it easily. Try practicing these calculations yourself! For more detailed insights, explore further resources or articles. Understanding these concepts will help improve your machining skills. Happy learning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Gear Tooth Pitch Calculation:Sure! To calculate the tooth pitch on a lathe gear, you need to know two things: the number of teeth and the diameter of the gear. You can find the pitch by dividing the diameter by the number of teeth. This tells you how far apart the teeth are. It helps the gear fit better and work smoothly.

Sure! Just let me know what question you’d like answered.

What Is The Formula For Calculating The Pitch Of Gear Teeth, And How Can It Be Applied To Lathe Gears?To find the pitch of gear teeth, you can use this formula: Pitch = Number of teeth ÷ Diameter of the gear. Pitch tells us how close the teeth are together. For lathe gears, knowing the pitch helps you choose the right gear for cutting materials. This way, we can make sure the machine works smoothly and makes the right shapes.

How Does The Number Of Teeth On A Gear Affect Its Pitch And The Resulting Gear Train Configuration In A Lathe?The number of teeth on a gear changes how it moves. More teeth mean slower movement but more power. Fewer teeth make the gear spin faster but with less force. This affects how gears fit together in a lathe, which helps us shape things like metal or wood. So, choosing the right number of teeth helps us get the best job done!

What Measurement Units Are Commonly Used To Express The Pitch Of Gear Teeth In Lathe Applications?In lathe work, we often use “module” and “diametral pitch” to talk about gear teeth pitch. The module tells us how big the teeth are in metric units. Diametral pitch shows how many teeth fit on a gear in inches. Both help us understand how gears will work together.

How Do You Determine The Proper Gear Tooth Pitch When Designing A Gear System For A Specific Lathe Workpiece?To find the right gear tooth pitch, you start by knowing the size of the workpiece. Then, you check how fast you want the gear to turn. This helps you choose a tooth pitch that fits well with the workpiece size and speed. You can also look at similar designs for help. Finally, make sure the gear can handle the work you want it to do!

What Are Some Practical Considerations When Selecting Gear Tooth Pitch For Improved Performance And Efficiency In Lathe Operations?When picking the gear tooth pitch for a lathe, think about how strong you want it. A finer pitch makes smooth cuts but can wear out faster. A coarser pitch is stronger but can be rough. You should also consider the material you’re working with and how fast you want to go. Matching the pitch to your project helps machines work better!